Company Advantages1. The raw materials of Smartweigh Pack are treated with several procedures. Materials enrichment, refining, and smelt process will be conducted to make the materials into a product with high purity. Less maintenance is required on Smart Weigh

packing machines

2. Strict quality assurance is under the control in Smartweigh Pack to ensure the quality. Smart Weigh vacuum packaging machine is set to dominate the market

3. sealing machines have such characteristics as , thus has good prospections. Smart Weigh packing machine features precision and functional reliability

4. sealing machines is widely used as it has the property of long service life and . The packing process is constantly updated by Smart Weigh Pack

5. sealing machines has been improved on the basis of the old types and such properties as have been realized. Smart Weigh packing machines are offered at competitive prices

Main parameters: |

Number of sealing head | 1 |

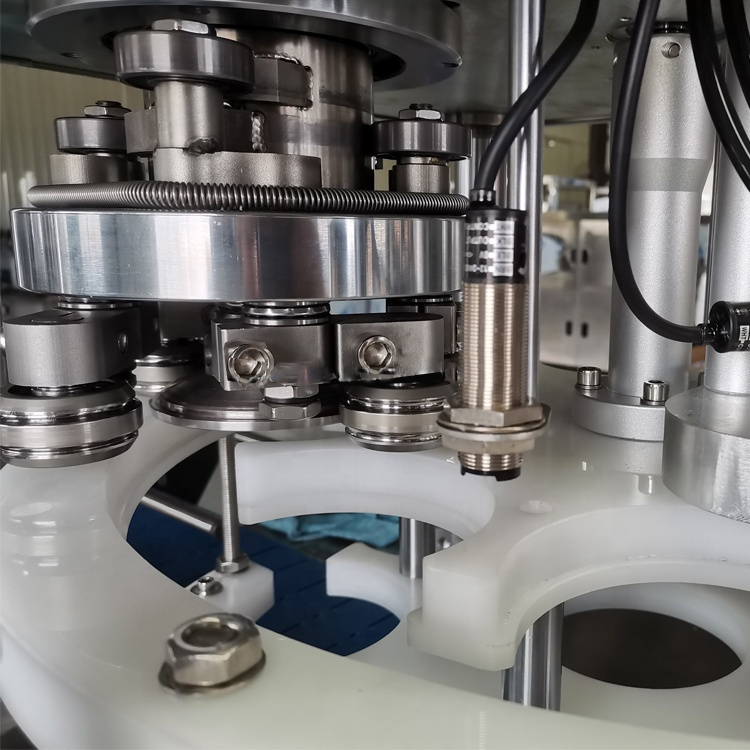

Number of seaming rollers | 4 (2 first operation, 2 second operation) |

Sealing speed | 33 cans/ min (Not adjustable) |

Sealing height | 25-220mm |

Sealing can diameter | 35-130mm |

Working temperature | 0-45℃ |

Working humidity | 35-85% |

Working power supply | Single-phase AC220V S0/60Hz |

Total power | 1700W |

Weight | 330KG (about) |

Dimensions | L 1850 W 8404H 1650mm |

Features: |

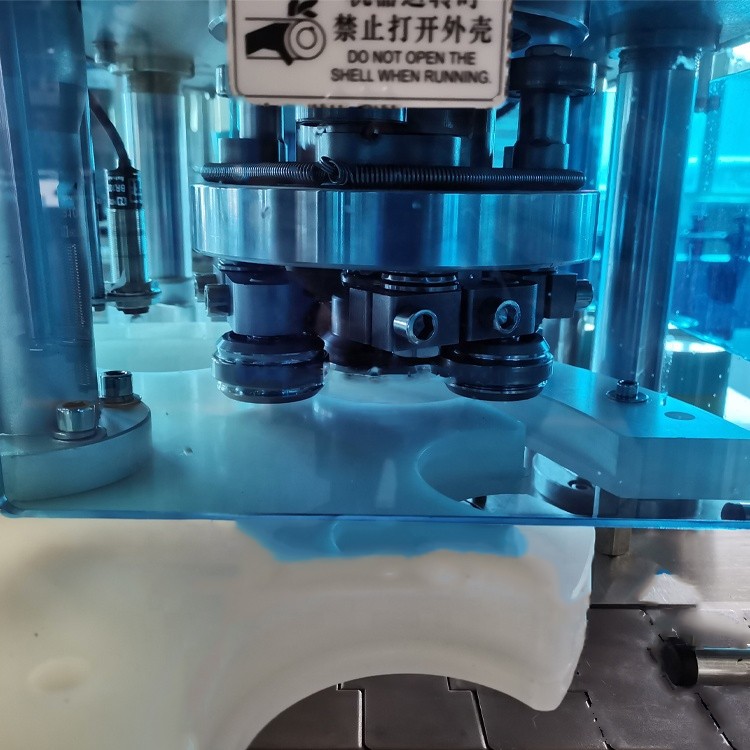

1. | Whole machine servo control makes the equipment run safer, more stable and smarter. The turntable only runs when there is a can, speed can be adjusted separately: when there is can stuck, the turntable will automatically stop. Ater one button reset, the error can be released and machine restart to run: When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial Equipment damage and safety accidents caused by incorre coperation of the equipment.

|

2. | A total of a seaming rollers are completed at the same time to ensure high sealing performance |

3. | The can body does not rotate during the sealing process, which is safer and is especially,suitable for fragile and liquld products. |

4. | The sealing speed is fixed at 33 cans per minute, production is automated, which improvesproduction efficiency and saves labor costs. |

Applicable to tin cans, aluminum cans, plastic cans and composite paper can, it is the idea packaging equipment for food, beverage, Chinese medicine drinks, chemical industry etc.

Company Features1. We have excellent manufacturing and innovation capabilities guaranteed by international advanced sealing machinesequipment.

2. Guangdong Smart Weigh Packaging Machinery Co., Ltd is capable of providing one stop solution for sealing machines. Ask!