ከ2012 ጀምሮ - ስማርት ዌይግ ደንበኞች ምርታማነትን በተመጣጣኝ ዋጋ እንዲያሳድጉ ለመርዳት ቁርጠኛ ነው።

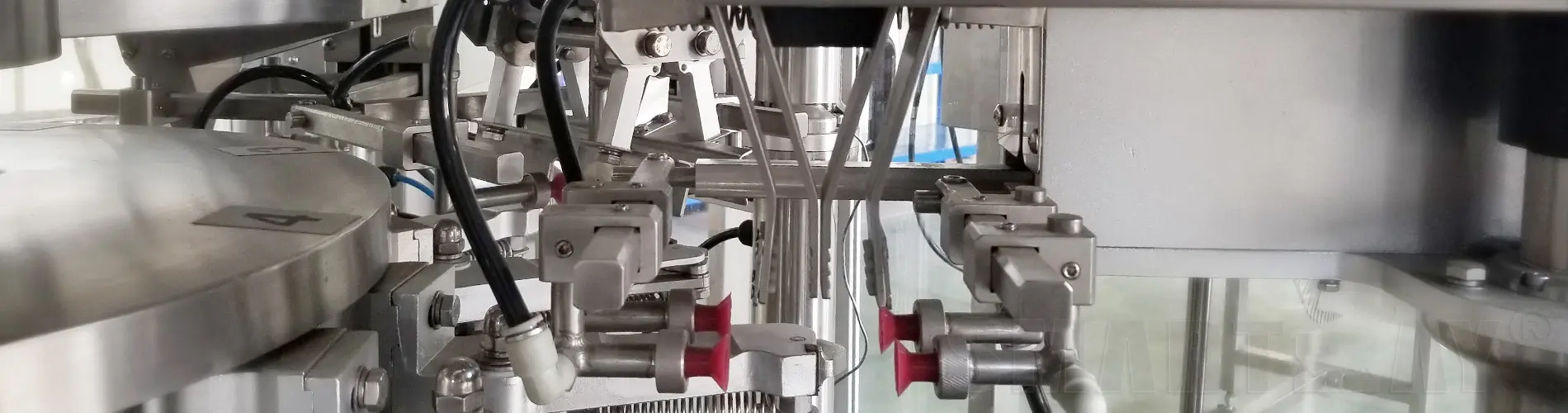

እንደ ዋና የከረጢት ማሸጊያ ማሽን አምራች ከቻይና የመጣነው እኛ 12 ዓመታት የኢንዱስትሪ ልምድ ያለን እኛ ስማርት ዌይግ ሰፊ የከረጢት ማሸጊያ ማሽኖችን በመንደፍ እና በማምረት ላይ እንሰራለን። የእኛ ፖርትፎሊዮ እንደ ሮታሪ ከረጢት ማሸጊያ ማሽን፣ አግድም ከረጢት ማሸጊያ ማሽን፣ የቫኩም ከረጢት ማሸጊያ ማሽን እና ኮምፓክት ሚኒ ከረጢት ማሸጊያ ማሽን ያሉ የላቁ ሞዴሎችን ያካትታል። እያንዳንዱ ማሽን የደንበኞቻችንን የተለያዩ ፍላጎቶች እንደሚያሟላ በትክክለኛነት እና በጥንቃቄ የተሰራ ነው።

የእኛ ዘመናዊ አስቀድሞ የተሰሩ የከረጢት ማሸጊያ ማሽኖች እጅግ በጣም ብዙ ቁሳቁሶችን እና አስቀድሞ የተሰሩ የከረጢት ቅርጸቶችን ለማስተናገድ የተነደፉ ናቸው። ይህም ሁለገብ የሆኑ የቆመ ከረጢቶችን፣ ክላሲክ ጠፍጣፋ ከረጢቶችን፣ ለአጠቃቀም ምቹ የሆኑ የዚፐር ዶይፓኮችን፣ በሚያምር ሁኔታ ደስ የሚሉ የ8 ጎን ማህተም ከረጢቶችን እና ጠንካራ ጠፍጣፋ የታችኛውን ከረጢቶችን ያካትታል። ይህ ሰፊ የተኳኋኝነት ክልል ንግዶች የተለያዩ ምርቶችን እንዲያሽጉ ያስችላቸዋል፣ ከገበያ አዝማሚያዎች እና ከሸማቾች ምርጫዎች ጋር በቀላሉ እንዲላመዱ ያስችላቸዋል። ብዙ ማሽኖች ሳያስፈልጉ የማሸጊያ ቅጦችን የመቀየር ችሎታ ምቾት ብቻ አይደለም፤ በዛሬው ፈጣን ገበያ ውስጥ ስትራቴጂካዊ ጥቅም ነው።

በስማርት ዌይግ፣ የማሸጊያ ፍላጎቶች ከማሽኑ በላይ እንደሚዘልቁ እንረዳለን። ለዚህም ነው ሁሉን አቀፍ የተርንኪ ማሸጊያ መፍትሄዎችን የምናቀርበው። እነዚህ መፍትሄዎች መክሰስ፣ ከረሜላ፣ ጥራጥሬዎች፣ ቡና፣ ለውዝ፣ ደረቅ ፍራፍሬዎች፣ ስጋ፣ የቀዘቀዘ ምግብ እና ለመበላት ዝግጁ የሆኑ ምግቦችን ጨምሮ ለተለያዩ ምርቶች የተነደፉ ናቸው። የተርንኪ መፍትሔዎቻችን ከምርት አያያዝ እና ክብደት እስከ ማሸግ እና ማሸግ የመጨረሻ ደረጃዎች ድረስ የማሸጊያ ሂደትዎን ለማቀላጠፍ የተነደፉ ናቸው። ይህ የተቀናጀ አካሄድ በማሸጊያ መስመርዎ ውስጥ ቅልጥፍናን፣ ወጥነትን እና ጥራትን ያረጋግጣል።

በተጨማሪም፣ ለፈጠራ እና ለጥራት ያለን ቁርጠኝነት በምርቶቻችን ላይ ብቻ አያበቃም። ደንበኞቻችን ምርጥ ማሽኖችን ብቻ ሳይሆን ምርጡን ተሞክሮም እንዲያገኙ በማረጋገጥ ልዩ የደንበኞች አገልግሎት እና ድጋፍ እናቀርባለን። እንደ ባለሙያ የከረጢት ማሸጊያ ማሽን አምራች ፣ የባለሙያዎቻችን ቡድን ለእርስዎ ፍላጎቶች ትክክለኛውን ማሽን እና ውቅር ከመምረጥ ጀምሮ እስከ ቀጣይነት ያለው የድጋፍ እና የጥገና አገልግሎቶችን እስከመስጠት ድረስ መመሪያ ለመስጠት ሁልጊዜ ዝግጁ ነው።

ብዙ ከረጢቶች በአንድ ጊዜ ሊሞሉ እና ሊታሸጉ የሚችሉበትን ካሮሰል በማሽከርከር ይሰራሉ። ይህ ዓይነቱ ማሽን ለተለያዩ ምርቶች ተስማሚ ነው፣ ለምሳሌ ፈሳሾችን፣ ዱቄቶችን እና ጥራጥሬዎችን ጨምሮ። ከፍተኛ ፍጥነት ያለው አሠራሩ ጊዜ እና ቅልጥፍና ወሳኝ ለሆኑ ትላልቅ የምርት አካባቢዎች ተስማሚ ያደርገዋል።

የተለመደው ሞዴል 8 ጣቢያዎች ያሉት ሮታሪ ከረጢት ማሸጊያ ማሽን ነው። በተጨማሪም፣ ለአነስተኛ እና ለትላልቅ የከረጢት መጠኖች ልዩ ሞዴሎችን እናቀርባለን።

ሞዴል | SW-R8-200R | SW-R8-300R |

የመሙላት መጠን | 10-2000 ግ | 10-3000 ግ |

የከረጢት ርዝመት | 100-300 ሚሜ | 100-350 ሚሜ |

የከረጢት ስፋት | 80-210 ሚሜ | 200-300 ሚሜ |

ፍጥነት | 30-50 ፓኮች/ደቂቃ | 30-40 ፓኮች/ደቂቃ |

የከረጢት ቅጥ | አስቀድሞ የተሰራ ጠፍጣፋ ከረጢት፣ የዶይፓክ፣ ዚፐር የተለጠፈ ቦርሳ፣ የጎን ጉሴት ከረጢቶች፣ የአፍንጫ ከረጢቶች፣ የሪቶርት ከረጢት፣ 8 የጎን ማኅተም ከረጢቶች | |

በአግድም ፍሰት ውስጥ አስቀድመው የተሰሩ ከረጢቶችን ያነሳሉ፣ ይከፍታሉ፣ ይሞላሉ እና ይዘጉታል። የአግድም ከረጢት ማሸጊያ ማሽኖች አነስተኛ አሻራ ስላላቸው እና ከ rotary ማሸጊያ ማሽን ጋር ሲነፃፀሩ ተመሳሳይ የፍጥነት አፈፃፀም ስላላቸው ትኩስ ምርት ይሆናሉ።

ሁለት የከረጢት የመመገቢያ መንገዶች አሉ፤ እነሱም ቀጥ ያለ ማከማቻ እና አግድም ማከማቻ ከረጢቶችን ለማንሳት። አቀባዊ ዓይነት ቦታ ቆጣቢ ዲዛይን ያለው ሲሆን የማከማቻ ከረጢቶችን ብዛት ግን ይገድባል፤ በምትኩ፣ አግድም ዓይነት ብዙ ከረጢቶችን ሊይዝ ይችላል፣ ነገር ግን ለዲዛይኑ ረዘም ያለ ቦታ ያስፈልገዋል።

ሞዴል | SW-H210 | SW-H280 |

የመሙላት መጠን | 10-1500 ግ | 10-2000 ግ |

የከረጢት ርዝመት | 150-350 ሚሜ | 150-400 ሚሜ |

የከረጢት ስፋት | 100-210 ሚሜ | 100-280 ሚሜ |

ፍጥነት | 30-50 ፓኮች/ደቂቃ | 30-40 ፓኮች/ደቂቃ |

የከረጢት ቅጥ | አስቀድሞ የተሰራ ጠፍጣፋ ከረጢት፣ የዶይፓክ፣ የዚፐር ቦርሳ | |

አነስተኛ የከረጢት ማሸጊያ ማሽኖች ለአነስተኛ ደረጃ ስራዎች ወይም ውስን ቦታ ላላቸው ተለዋዋጭነት ለሚያስፈልጋቸው ንግዶች ፍጹም መፍትሄ ናቸው። እነዚህ ማሽኖች አነስተኛ መጠን ቢኖራቸውም፣ የከረጢት መክፈት፣ መሙላት፣ ማሸግ እና አንዳንድ ጊዜ ማተምን ጨምሮ በአነስተኛ ጣቢያ ውስጥ የተለያዩ ተግባራትን ያቀርባሉ። እነዚህ ማሽኖች የኢንዱስትሪ ማሽኖችን ሳይጠቀሙ ውጤታማ የማሸጊያ መፍትሄዎችን ለሚፈልጉ ጅምር ኩባንያዎች ወይም አነስተኛ ንግዶች ተስማሚ ናቸው።

ሞዴል | SW-1-430 | SW-4-300 |

የስራ ጣቢያ | 1 | 4 |

የከረጢት ርዝመት | 100-430 ሚሜ | 120-300 ሚሜ |

የከረጢት ስፋት | 80-300 ሚሜ | 100-240 ሚሜ |

ፍጥነት | 5-15 ፓኮች/ደቂቃ | 8-20 ፓኮች/ደቂቃ |

የከረጢት ቅጥ | አስቀድሞ የተሰራ ጠፍጣፋ ከረጢት፣ የዶይፓክ፣ ዚፐር የተለጠፈ ቦርሳ፣ የጎን ጉሴት ከረጢት፣ ኤም ከረጢት | |

ሞዴል | SW-ZK14-100 | SW-ZK10-200 |

የመሙላት መጠን | 5-50 ግ | 10-1000 ግ |

የከረጢት ርዝመት | ≤ 190 ሚሜ | ≤ 320 ሚሜ |

የከረጢት ስፋት | 55-100 ሚሜ | 90-200 ሚሜ |

ፍጥነት | ≤ 100 ቦርሳዎች/ደቂቃ | ≤ 50 ቦርሳዎች/ደቂቃ |

የከረጢት ቅጥ | አስቀድሞ የተሰራ ጠፍጣፋ ከረጢት | |

ቀድሞ የተሰሩ የኪስ መሙያ ማሽኖች መስመራዊ መመዘኛዎችን፣ ባለብዙ ጭንቅላት መመዘኛዎችን፣ የቮልሜትሪክ ኩባያ መሙያዎችን፣ የኤገር መሙያዎችን እና ፈሳሽ መሙያዎችን ያካትታሉ።

የምርት አይነት | የምርቶች ስም | የከረጢት ማሸጊያ ማሽን አይነት |

የጥራጥሬ ምርቶች | መክሰስ፣ ከረሜላ፣ ለውዝ፣ ደረቅ ፍራፍሬዎች፣ እህሎች፣ ባቄላ፣ ሩዝ፣ ስኳር | ባለብዙ ራስ ክብደት/መስመራዊ ክብደት ከረጢት ማሸጊያ ማሽን |

የቀዘቀዘ ምግብ | የቀዘቀዘ የባህር ምግብ፣ የስጋ ቦልሶች፣ አይብ፣ የቀዘቀዙ ፍራፍሬዎች፣ ዱባዎች፣ የሩዝ ኬክ | |

ለመብላት ዝግጁ የሆነ ምግብ | ኑድል፣ ስጋ፣ የተጠበሰ ሩዝ፣ | |

ፋርማሲዩቲካል | ክኒኖች፣ ፈጣን መድኃኒቶች | |

የዱቄት ምርቶች | የወተት ዱቄት፣ የቡና ዱቄት፣ ዱቄት | የአገር መሙያ ከረጢት ማሸጊያ ማሽን |

ፈሳሽ ምርቶች | ሶስ | ፈሳሽ መሙያ ከረጢት ማሸጊያ ማሽን |

ለጥፍ | የቲማቲም ፓስታ |

ህንፃ ቢ፣ ኩንክሲን ኢንዱስትሪያል ፓርክ፣ ቁጥር 55፣ ዶንግ ፉ መንገድ፣ ዶንግፌንግ ከተማ፣ ዞንግሻን ከተማ፣ ጓንግዶንግ ግዛት፣ ቻይና፣ 528425

ኢሜይል፡export@smartweighpack.com

ስልክ: +86 760 87961168

ፋክስ፡ +86-760 8766 3556

አድራሻ፡ ህንፃ ቢ፣ ኩንክሲን ኢንዱስትሪያል ፓርክ፣ ቁጥር 55፣ ዶንግ ፉ መንገድ፣ ዶንግፌንግ ከተማ፣ ዞንግሻን ከተማ፣ ጓንግዶንግ ግዛት፣ ቻይና፣ 528425