Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

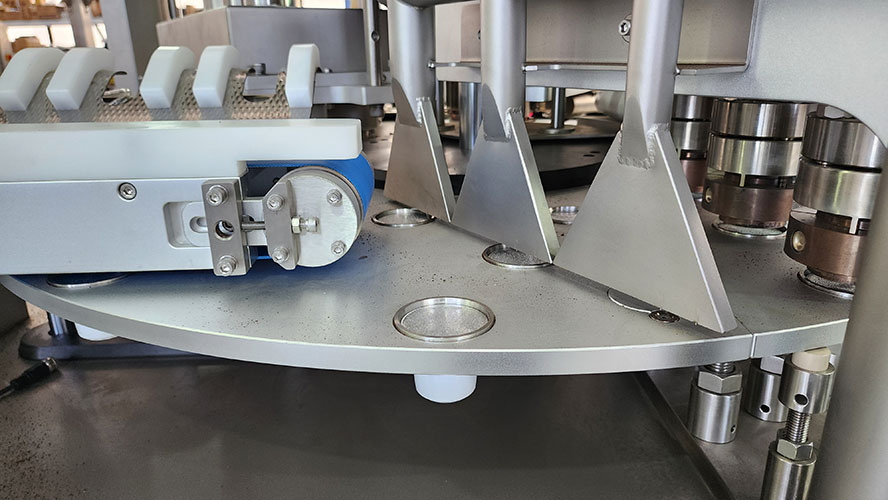

Smart Weigh's SW-KC series offers advanced solutions tailored for K-Cup production. These machines integrate the functionalities of K-Cup filling, sealing, and packaging, ensuring a streamlined and efficient manufacturing process.

SEND INQUIRY NOW

If you're aiming to elevate your single-serve coffee production line, Smart Weigh's SW-KC series offers advanced solutions tailored for K-Cup production. These machines integrate the functionalities of K-Cup filling, sealing, and packaging, ensuring a streamlined and efficient manufacturing process.

Smart Weigh's SW-KC series is engineered to meet the demands of modern coffee manufacturers. These machines serve as comprehensive K-Cup manufacturing solutions, combining the roles of K-Cup filling machines, sealing machines, and packaging equipment. With a production capacity ranging from 180 cups per minute, they cater to both small-scale and large-scale operations.

| Model | SW-KC03 |

| Capacity | 180 cups/minute |

| Container | K cup/capsule |

| Filling Weight | 12 grams |

| Accuracy | ±0.2g |

| Power consumption | 8.6KW |

Air consumption | 0.4m³/min |

| Pressure | 0.6Mpa |

| Voltage | 220V, 50/60HZ, 3 phase |

| Machine Size | L1700×2000×2200mm |

Filling Precision: A high-resolution servo auger, paired with real-time weight feedback, maintains ±0.2 g accuracy—even with micro-ground specialty coffees or functional additives. Decades of powder-handling R&D are built into the software’s adaptive dosing algorithm, ensuring consistent yield and preserving flavor profiles as you introduce new SKUs.

Efficiency: The rotary turret indexes at 60 cycles per minute, and each turret nests three capsules—delivering a sustained output of 180 capsules/minute on a single lane. This throughput translates to >10,000 pods per shift, letting you consolidate multiple legacy fillers into one footprint and freeing space for future roasting or packaging lines.

Sanitation: Engineered to GMP standards, every product-contact surface is crafted with seamless 304/316L stainless steel and radiused corners to eliminate dirt traps. Tool-free disassembly shortens your sanitation cycles and supports increasingly strict FSMA and retailer audits, helping your plant stay audit-ready as food-safety expectations rise.

Safety & Protection: An interlocked “open-door stop” mechanism halts the entire system the moment a guard door is unlatched, while a TÜV-certified safety relay continuously monitors all circuits. This dual layer of protection safeguards operators against accidental contact, reduces downtime caused by emergency stops, and aligns with evolving global safety regulations—future-proofing your production floor.

Changeable Formula (Zero-Adjustment Recipe Switching): Digital "recipe cards" store auger speed, dwell time, vacuum assist, and nitrogen flush parameters. When you select a new blend on the HMI, the machine auto-reconfigures without manual tweaks or mechanical parts swaps, slashing changeover to under 5 minutes and enabling agile, small-batch production that responds to market trends.

Stabilization: A hybrid drive train—servo indexing for precise positioning and a robust mechanical cam for sealing—delivers both accuracy and longevity. The balanced design minimizes vibration, extending component life and maintaining seal integrity even as production volumes scale up in the years ahead.

Easy to Clean: The quick-release hopper slides horizontally on guide rails, so operators can pull it clear for washdown without lifting equipment overhead. This ergonomic, spill-free removal cuts clean-in-place time, reduces allergen-cross-contamination risk, and supports lean sanitation staffing models.

Firm & Aesthetic Sealing: A proprietary "floating ring" heat-sealing head adapts to slight lid-stock variations, producing wrinkle-free seams that pass 100 kPa burst tests while showcasing a retail-ready appearance. Consistent, visually appealing seals reinforce brand quality and help you meet premium-pod shelf-presentation standards.

Human-Centered Operation: Built on object-oriented PLC architecture, the UI mirrors smartphone logic—drag-and-drop recipe icons, contextual pop-ups, and multilingual support. New hires reach full proficiency in days, not weeks, decreasing onboarding costs and making the system adaptable for a diverse, global workforce.

Smart Weigh stands out in the industry for its commitment to innovation and quality. The K-Cup filler machines are designed with the latest technology to ensure reliability and efficiency. By integrating multiple functions into a single unit, they reduce the need for multiple machines, saving on space and operational costs.

Let Smart Weigh's SW-KC series coffee capsule filling and sealing machine improve your manufacturing process with its unsurpassed efficiency, pinpoint accuracy, and high hygiene standards. With our SW-KC series equipment, you can increase productivity and profitability in the coffee capsule packing industry. With Smart Weigh, you can easily navigate towards premium coffee experiences with a single button click.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved