Ƙwararrun Ƙwararrun Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙaƙwalwa marufi kayan aiki Line Production

Aikace-aikace | Abinci, Abin sha, Likitanci, Pharmaceutical, Hatsi da dai sauransu |

Sunan injin | Injin kwalba/Cikin cikawa |

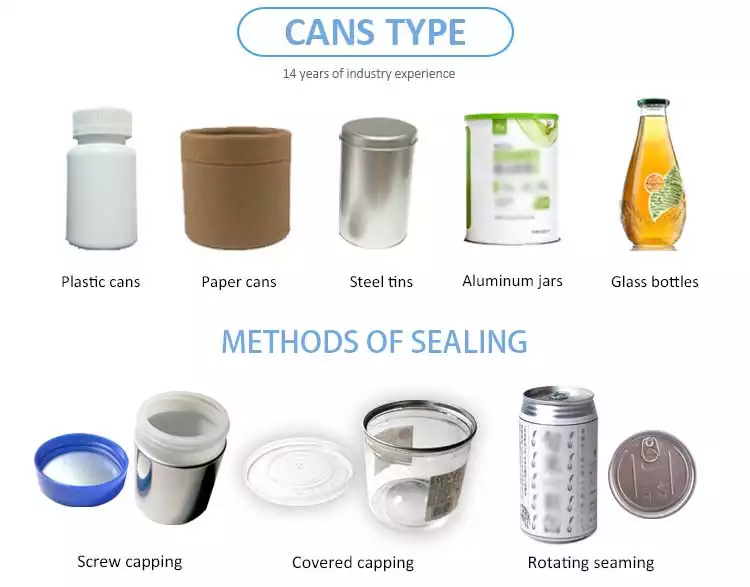

Kayan tattarawa | Filastik, takarda, karfe, Tin Can |

Digiri na atomatik | Cikakken-atomatik |

Nau'in tuƙi | Wutar Lantarki |

Saurin cikawa | 30-50bottles / min, ya dogara da nauyin kowane kwalban |

Cika daidaito | ± 1% |

Cika kewayon nauyi | 50-2000 g |

Hanyar aunawa | Electroni awo/Piston filler/Pump |

Tushen wutan lantarki | Mataki na uku 380/220V 50-60Hz/2kw |

Abubuwan mahimmanci | Motoci, PLC da dai sauransu |

Kayan na'ura | Bakin karfe 304 ko 316 |

Nauyi | 720KGS |

Girma (L*W*H) | 3000x900x1800mm |

1. An sanye shi da kariyar aminci, bi m's aminci management bukatun.

2. Aikace-aikace masu sassauƙa don Hatsi, Granule, ko Granules masu haɗa kayan ruwa Bottling ko Canning ta canza kayan aiki daban-daban. Granule da samfuran hatsi suna yin allura ta hanyar ma'aunin shugabanni da yawa ko ma'aunin Liner. Abubuwan da ake amfani da ruwa ta hanyar Filler ko Pump.

3. Yi amfani da PLC Servo System da tsarin kula da pneumatic da babban allon taɓawa don tsara cibiyar kula da tuƙi wanda ke haɓaka injin duka.'s sarrafa daidaici, dogaro da kaifin basira.

4. Touch allo iya adana fasaha sigogi na daban-daban irin kayayyakin, shi ne ba dole ba a sake saiti yayin da kayayyakin.

canzawa.

5. Tare da kuskuren nuna tsarin , wanda ke taimakawa wajen magance matsalar nan da nan.

6. Akwai don haɗi tare da na'ura na Capping, duba sikelin, Labeling Machine da cartoning machine don samun dukan kwalabe ko Cans marufi line.

7.Duk sassan da majalisai da ke hulɗa da foda an yi su ne daga S.S.304 kuma ana iya cirewa da sauƙi don canza canji.

8. BABU IYA, BA A CIKA" Tsarin yana kawar da ɓarna na foda mai tsada, kawai lokacin da za'a iya aiki sannan a fara cikawa.

9. Can Ciyar da aka sarrafa ta hanyar servo tsarin fasali tare da barga aiki da kuma daidai matsayi.

10.Powder Filling tsarin an sarrafa shi ta hanyar tsarin servo tare da daidaitawar saurin cikawa da daidaitattun daidaito

Wannan na'ura mai cike da ma'auni ta atomatik da injin marufi ya dace da ɗaukar granule, yanki, yi ko kayan sigar da ba ta dace ba kamar alewa, iri, jelly, soya, granule kofi, gyada, abinci mai bushewa, biscuit, cakulan, goro, abincin dabbobin yogurt, abinci daskararre. , da dai sauransu.