Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Widely used in the food and non-food industries, weigher machine can help you weigh materials quickly and can also work with packaging machines for automatic packaging. However, the types of combination weighers are complex, and different models of multi-head weighers have different functions and specially designed structures. Therefore, it is particularly important to learn to choose a suitable multihead weigher.

The selection of multi-head weighers mainly refers to the following factors:

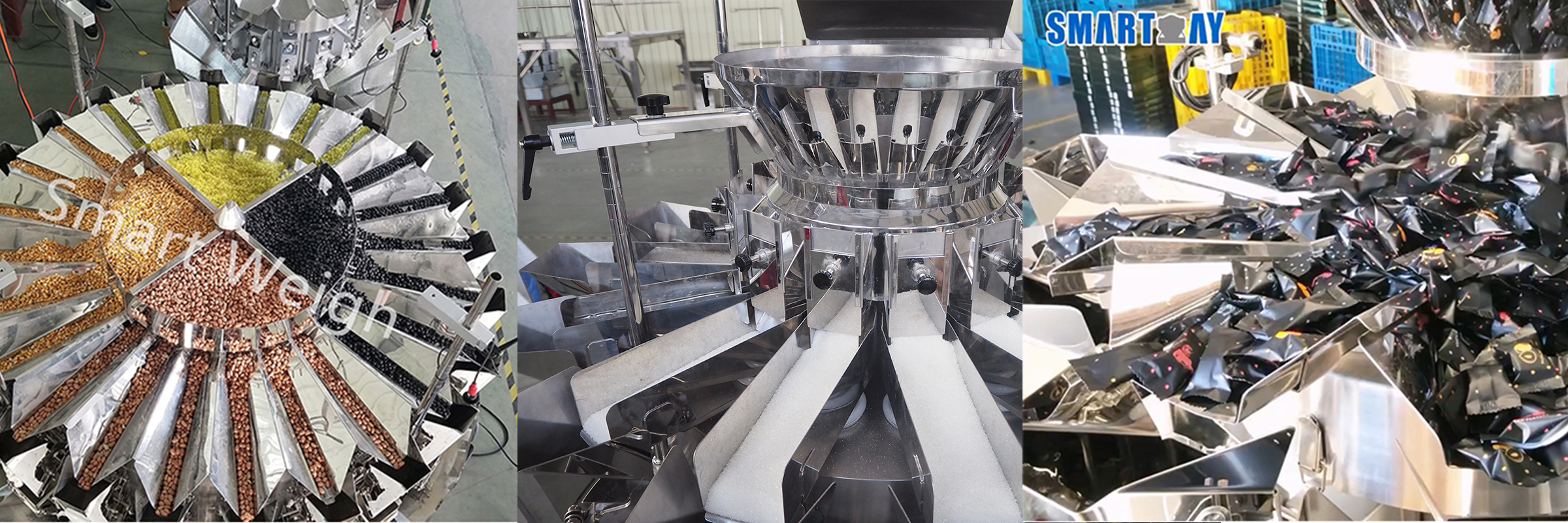

For products with high precision requirements, if it is a light weight and small package, we recommend a mini 14 head weigher with accuracy of 0.1-0.8 g; if it is a large weight and large package of food, try to choose a multi-head weigher with a large number of weighing heads. The more weighing heads, the more precise the combined operation.

Mini multihead weigher for marijuana, CBD candy, pills, etc.

For products with higher speed requirements, you can refer to the frequency of load cell, because higher frequency means shorter settling time.

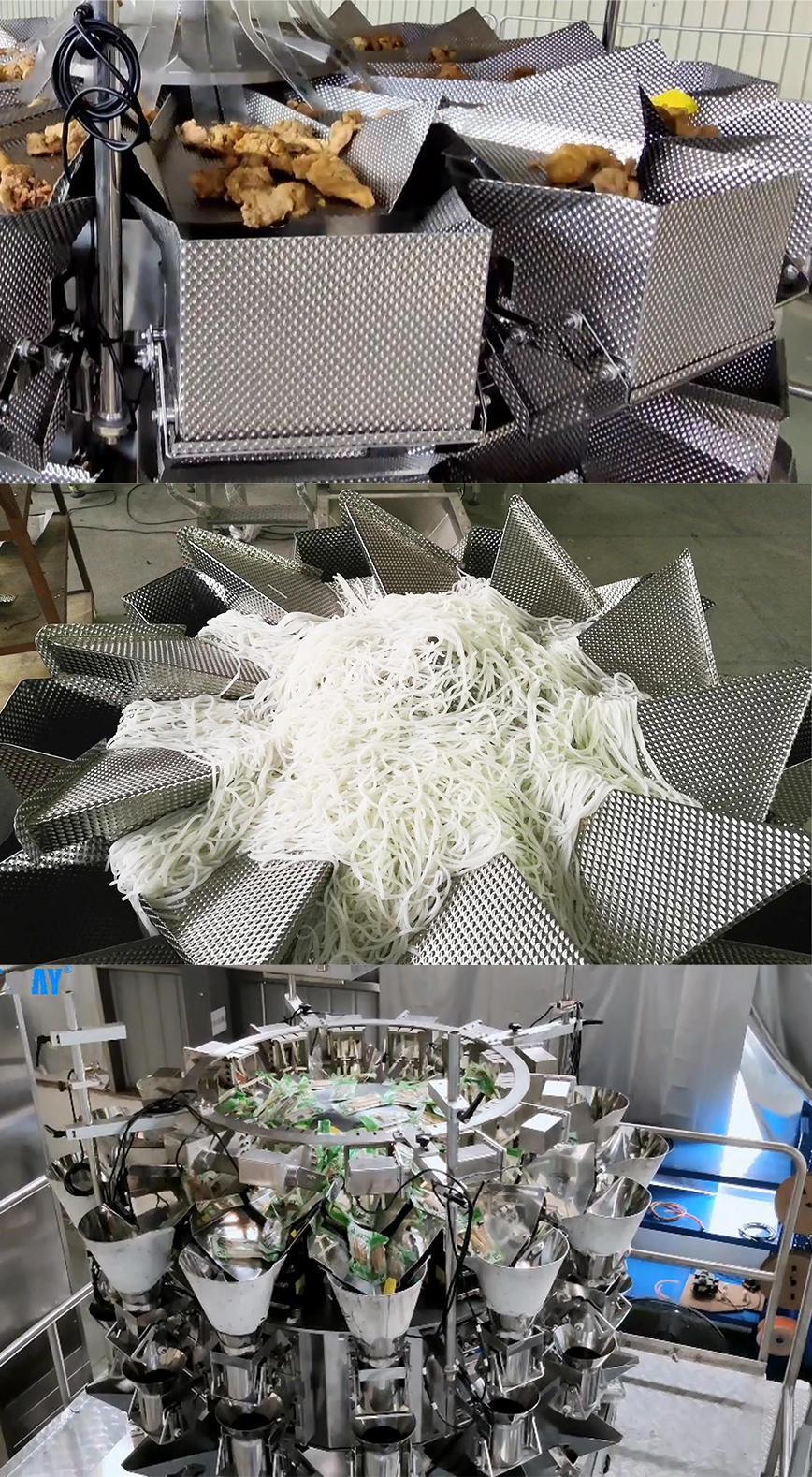

The size and shape of the hopper should match the volume, length and shape of the material. For example, a customized 7L 14-head weigher can accommodate long strips material within 21cm, a noodle weigher is suitable for products with a maximum length of 300mm, and a 16-head stick shape weigher is suitable for materials with a maximum length of 200mm and stick shape.

If the size or shape of the hopper does not match the material, the product will be easily stuck or even pinched during the weighing process, resulting in material waste and affecting the weighing accuracy.

The food industry has high requirements for food safety, and a multi-head weigher made of SUS304 stainless steel should be selected to avoid metal mixing into food and ensure food safety.

For viscous materials, dimple plate hopper (Teflon coating) is an ideal choice. By reducing the contact area with the material, it can effectively improve the fluidity of the material and prevent the material from sticking.

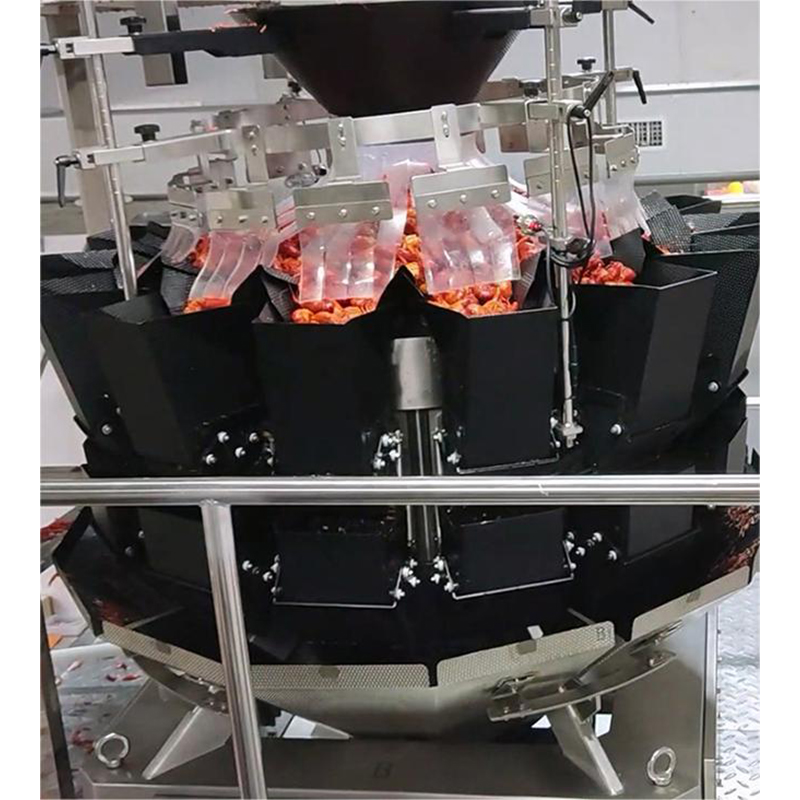

In order to meet the needs of diversified food packaging, customizing special multi-head weighers can make you do more with less. For example, a 24 heads mixture weigher can weigh multiple products at the same time, which not only improves efficiency, but also saves costs and plant space. White sugar weigher with leak-proof device can improve the weighing accuracy of small particles and help you reduce the waste of materials. The 16-head bag in bag weigher can meet the dual requirements of quantity and weight at the same time.

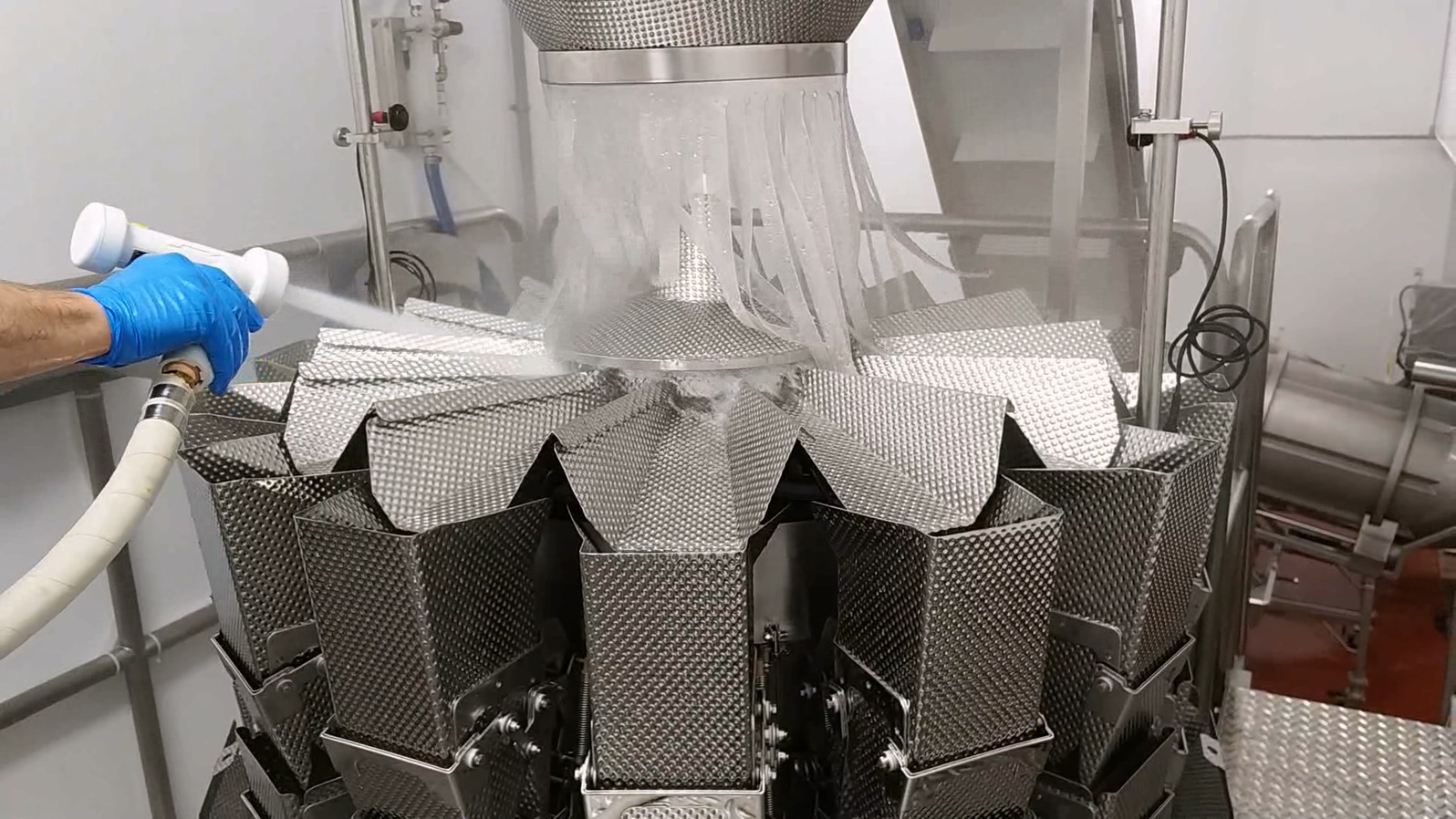

bgChoosing a multi-head weigher with low driving power not only has low energy consumption, but also has low noise, stable operation and low maintenance cost. In order to facilitate daily cleaning work, try to choose a multi-head weigher with IP65 waterproof level, and the parts in contact with food can be manually disassembled and washed directly.

If the workshop environment is humid, there is a lot of steam, and the packaged materials are rich in oil, vinegar, salt, etc., ordinary multi-head weighers are easily damaged. It is recommended to choose a multi-head weigher made of 304 stainless steel and anodized aluminum, which can reduce maintenance costs.

In order to reduce the production cost, many food factories tend to buy multiple cheap standard multi-head weighers. But more importantly, formulate the optimal weighing and packaging plan, rationally allocate the workshop space, and obtain the highest profit with the lowest cost.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved