Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Regular maintenance, cleaning, and sticking to the user manual help maintain or increase the efficiency of an automatic powder packaging machine. Nonetheless, there are other steps you can take to improve its efficiency. Please read on!

What does a powder packaging machine do?

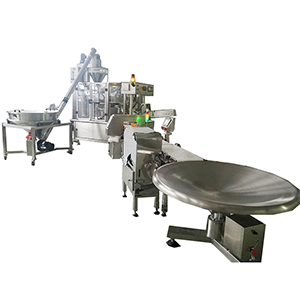

A powder packaging machine deals with the products in the form of powder. For instance, Albumen powder, milk powder, tiny white sugar, solid drink, coffee powder, nutrition powder, and so on.

Moreover, it is responsible for the following actions:

· It loads the materials.

· It weights.

· It fills.

· It packs.

When it comes to packaging, this equipment usually employs a hybrid of electrical and mechanical parts for the best results. Filling by volume or weight, feeding by auger or screw, and airtight packaging are all possible powder-preserving machine additions.

Machines like these see widespread use in the food, pharmaceutical, and chemical industries, among others, because of the importance of careful and efficient packaging in these fields. The machines could additionally have control systems to monitor the packaging procedure and make necessary adjustments.

If a business wants to streamline its powder packaging operations and increase efficiency and accuracy, it needs an auger filler powder packing machine.

Finally, you can adapt to container types that meet your requirements, including bags, pouches, bottles, jars, and cans. Different package style cannot be handled by the same machine, so choose the right container type is the key to the success of packaging.

Additionally, you should consider finding a reliable supplier who can help you with choosing materials and selecting equipment that best suits your production needs.

Increasing the efficiency of a powder packaging machine

To improve efficiency, you can take the following steps:

· Never skip scheduled maintenance or overhaul.

· Regularly clean.

· Stick to the user manual that came with the machine.

· Train your workers on how to use it efficiently.

· Regularly check all the mechanical and electrical parts of the machine.

· Adjust the motor speeds as per your needs. Overspeeding can cause a spike in power bills and mishandling the product on the manual end.

· Contact the manufacturer in case of an unexpected outcome.

· Streamline and enhance manufacturing processes by working smartly.

Benefits of increased efficiency

With an efficient powder packaging machine, the possibilities are endless. Firstly it is mostly automated, so you need fewer hands to do the extra work. So, it saves you a lot of money in terms of labor costs.

Secondly, an efficient machine is much faster and more accurate. This factor can help you maintain a good and trusted name in the market. So your brand will prosper.

Finally, an efficient machine will likely consume less maintenance cost. At Smart Weigh, we have manufactured highly efficient powder-packing machines. You can ask for a FREE quote now!

Conclusion

Taking care of your machines always benefits you in terms of better productivity and efficiency. So, always keep the user manual of your powder packing machine close to you and ask your maintenance staff to be vigilant. Thanks for the Read!

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved