Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

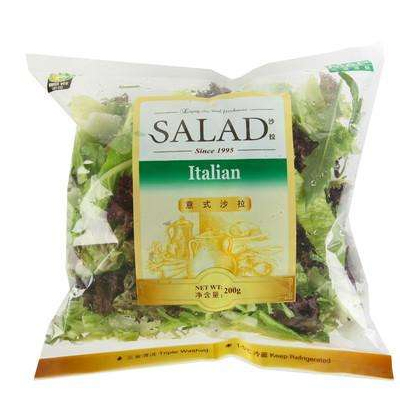

Lettuce Leafy Vegetables Vertical Packing Machine

1. Incline conveyor

2. 5L 14 head multihead weigher

3. Supporting platform

4. Incline conveyor

5. Vertical packing machine

6. Output conveyor

7. Rotary table

Model | SW-PL1 |

Weight (g) | 10-500 grams of vegetables |

Weighing Accuracy(g) | 0.2-1.5g |

Max. Speed | 35 bags/min |

Weigh Hopper Volume | 5L |

| Bag Style | Pillow bag |

| Bag Size | Length 180-500mm, width 160-400mm |

Control Penal | 7" Touch Screen |

Power Requirement | 220V/50/60HZ |

The salad packaging machine fully-automatically procedures from material feeding, weighing, filling, forming, sealing, date-printing to finished product output.

Electronic control system label dispenser machine LD-130 Specifications:

| Model | LD-100 | LD-130 | LD-180 |

Available Width: | 5 - 100mm | 5 - 130mm | 5 - 180mm |

| Stripping label length | 4-250mm | 4 - 250mm | 4 - 250mm |

| Feed Speed | 5m/min | 5m/min | 5m/min |

| Max. OD of Roll | 250mm | 250mm | 250mm |

| Inner of roller | ≥25mm | ≥25mm | ≥25mm |

| Power Supply | AC110/220V | AC110/220V | AC110/220V |

| Measurement | 136*174*280mm | 166*174*280mm | 206*174*280mm |

| N/G weight | 3.6/4.5Kg/pcs | 4.1/5.0Kg/pcs | 5.2/6.0Kg/pcs |

| Please inform us the label size when you order! :-) | |||

Feature:

Method of use:

Note: For wide labels, will pull out of tag bottom paper screened sensor. pls pay attention.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved