Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Always striving toward excellence, Smart Weigh has developed to be a market-driven and customer-oriented enterprise. We focus on strengthening the capabilities of scientific research and completing service businesses. We have set up a customer service department to better provide customers with prompt services including order tracking notice. packaging equipment manufacturers Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product packaging equipment manufacturers or our company, feel free to contact us.The product dehydrates the food evenly and thoroughly. During the drying process, heat conduction, and radiant heat transfer are perfectly utilized to ensure the hot air fully contacts with the food.

| Item | SW-160 | SW-210 | |

| Packing Speed | 30 - 50bags / min | ||

| Bag Size | Length | 100 - 240mm | 130 - 320mm |

| Width | 80 - 160mm | 100 - 210mm | |

| Power | 380v | ||

| Gas Consumption | 0.7m³ / min | ||

| Machine Weight | 700kg | ||

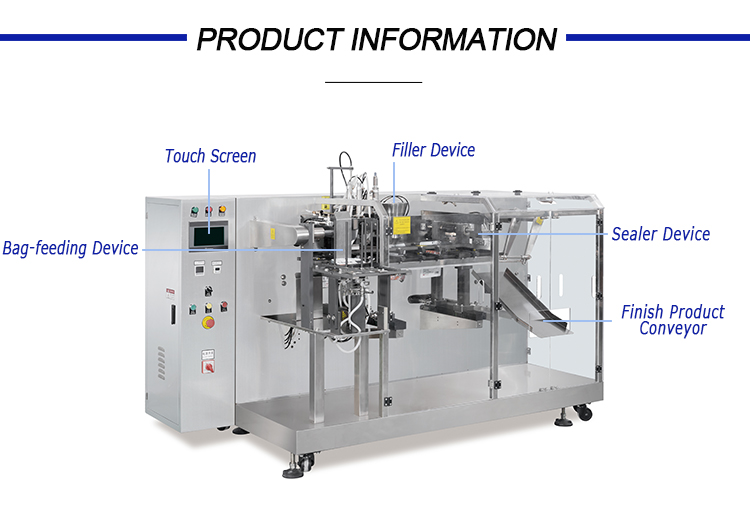

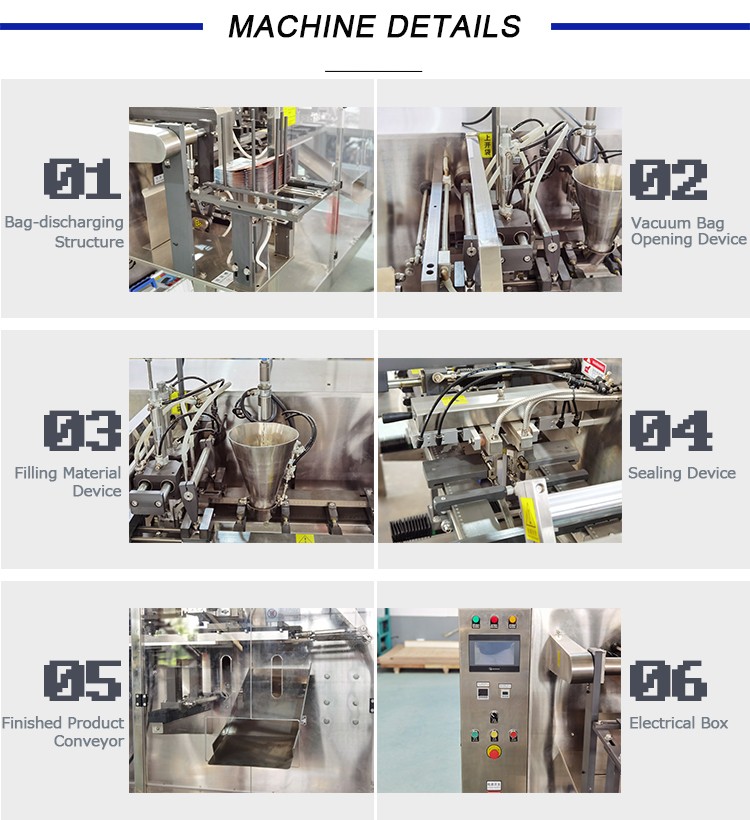

The machine adopts the appearance of stainless 304, and the carbon steel frame part and some parts are processed by acid-proof and salt-resistant anti-corrosion treatment layer.

Material selection requirements: Most of the parts are molded by moulding.The main materials are 304 stainless steel and alumina.bg

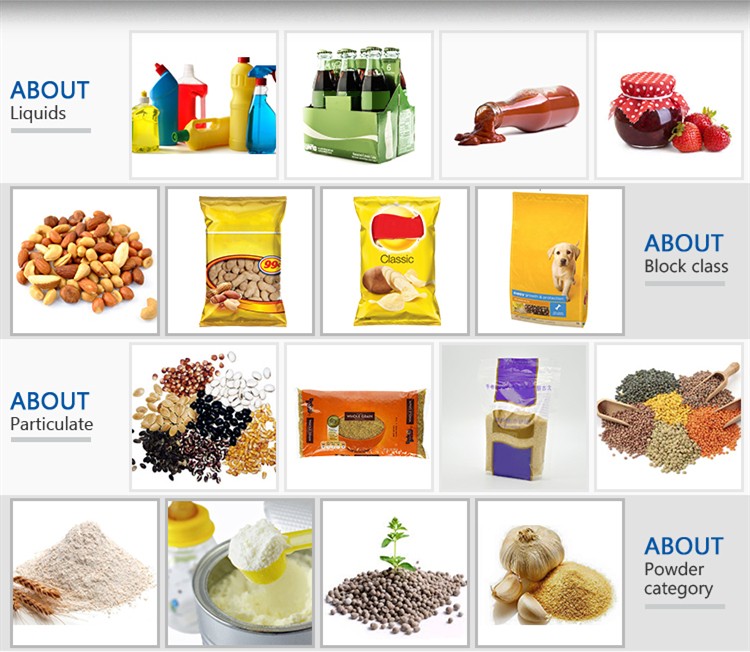

The Filling System is Just for Your Reference.We Will Offer You the Best Solution According to Your Product Mobility, Viscosity, Density, Volume, Dimensions, Etc.

Powder Packing Solution —— Servo Screw Auger Filler Is Specialized for Power Filling Such as Nutrients Power, Seasoning Powder, Flour, Medicinal Powder, Etc.

Liquid Packing Solution —— Piston Pump Filller Is Specialized for Liquid Filling Such as Water, Juice, Laundry Detergent, Ketchup, Etc.

Solid Packing Solution —— Combination Multi-head Weigher Is Specialized for Solid Filling Such as Candy, Nuts, Pasta, Dried Fruit, Vegetable, Etc.

Granule Pack Solution —— Volumetric Cup Fillier Is Specialized for Granule Filling Such as Chemial, Beans, Salt, Seasoning, Etc.

To draw in more users and consumers, industry innovators are continually developing its qualities for a larger range of application scenarios. Additionally, it can be customized for clients and has a reasonable design, all of which help grow the customer base and loyalty.

Regarding the attributes and functionality of the packaging equipment manufacturers, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In China, ordinary working time is 40 hours for employees who work full time. In Smart Weigh Packaging Machinery Co., Ltd., most employees work abiding by this kind of rule. During their duty time, each of them devotes their full concentration to their work so as to provide customers with the highest-quality Inspection Machine and an unforgettable experience of partnering with us.

Regarding the attributes and functionality of the packaging equipment manufacturers, it is a kind of product that will always be in vogue and offer consumers limitless benefits. It can be a long-lasting friend for people because it is constructed from high-quality raw materials and has a lengthy lifespan.

In essence, a long-standing packaging equipment manufacturers organization runs on rational and scientific management techniques that were developed by smart and exceptional leaders. The leadership and organizational structures both guarantee that the business will offer competent and high-quality customer service.

Smart Weigh Packaging Machinery Co., Ltd. always considers communicating through phone calls or video chat the most time-saving yet convenient way, so we welcome your call for asking for the detailed factory address. Or we've displayed our e-mail address on the website, you are free to write an E-mail to us about the factory address.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved