Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. powder filling line If you are interested in our new product powder filling line and others, welcome you to contact us.The product benefits people by retaining the original nutrients of food such as vitamins, minerals, and natural enzymes. A journal of American even said that the dried fruits had twice the amount of antioxidants as their fresh ones.

| MR Series | SW-200R | SW-200RW | SW-300R | -400R |

|---|---|---|---|---|

| Capacity | up to 80bags/min | up to 80bags/min | up to 80bags/min | up to 80bags/min |

| Filling Volume | 5 – 2500g | 5 – 2500g | 10 – 2500g | 10 – 3500g |

| Total Power Consumption | 3.3kw | 3.3kw | 3.3kw | 3.3kw |

| Dimension | 1460 * 2500 * 1400mm | 1710 * 1505 * 1640mm | 2460 * 1830 * 1460mm | 2400 * 1750 * 1600mm |

| Compress Air Requirement (supply by user) | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min |

| Bag Width | 55 – 200mm 2 – 7.9in | 55 – 200mm 2 – 7.9in | 180 – 300mm 7 – 11.8in | 280 – 400mm 11 – 15.7in |

| Bag Length | ≤ 350mm ≤ 13.8in | ≤ 350mm ≤ 13.8in | ≤ 350mm ≤ 13.8in | ≤ 650mm ≤ 25.6in |

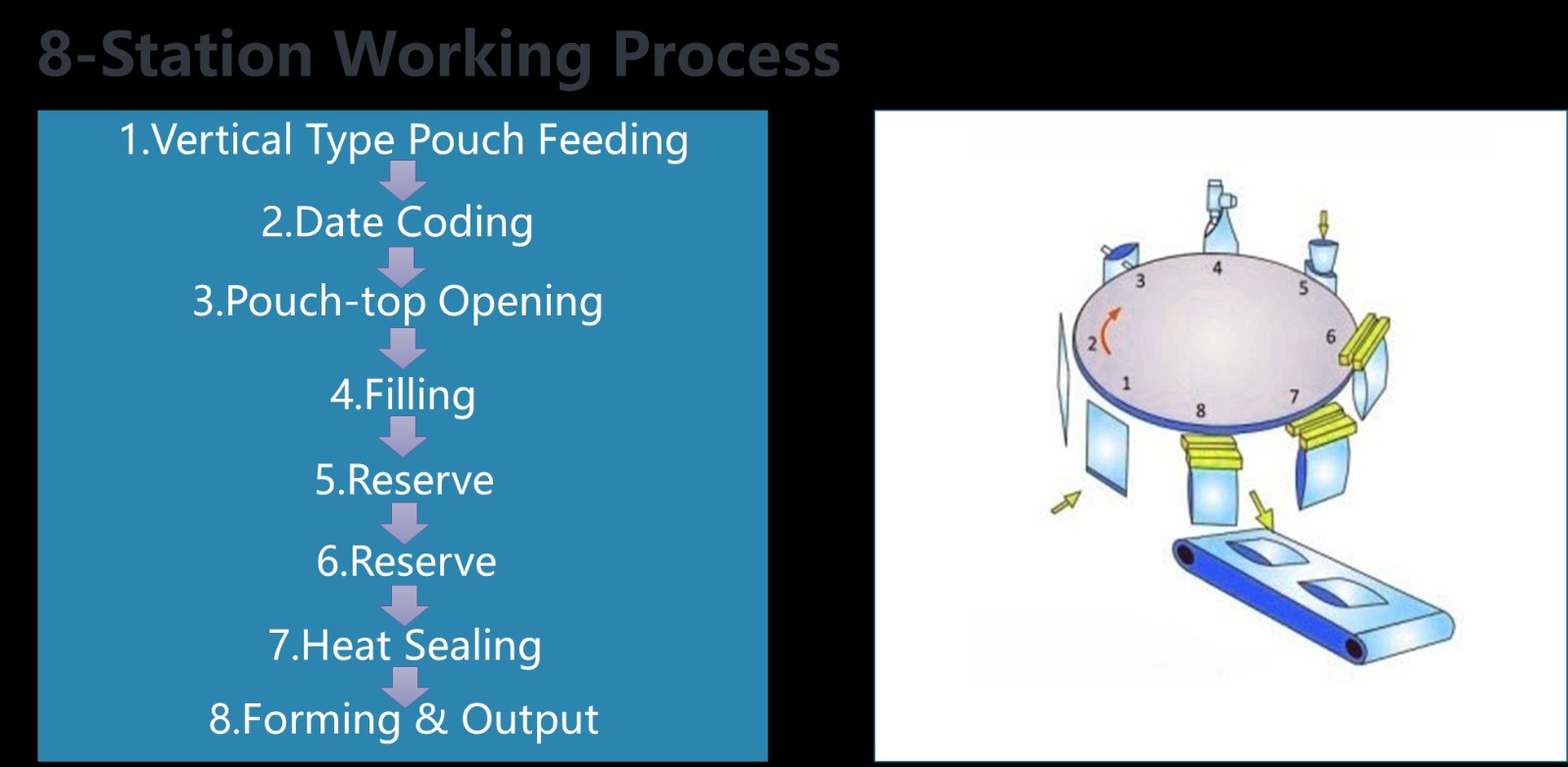

CE 6/8 working stations automatic rotary powder premade bag packaging machine masala pouch packing sealing machine

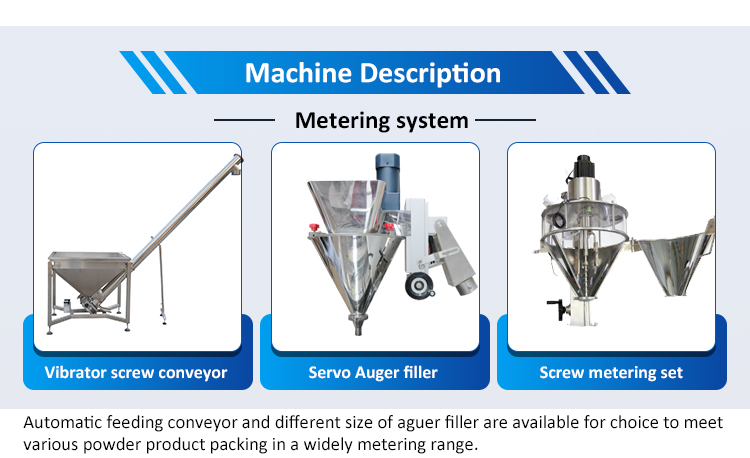

All kinds of powder, like milk powder, coffee, spices, additives ,washing powder,seasoning,sugar powder, coffee powder, wheat flour, detergent powder, coconut powder, etc.

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved