Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Ten Multi-lane vertical stick pack instant coffee packing machines were ordered by a Portuguese customer from Smart Weigh, which successfully addressed the issue of automatic powder packing and prevented powder leakage during the packaging process.

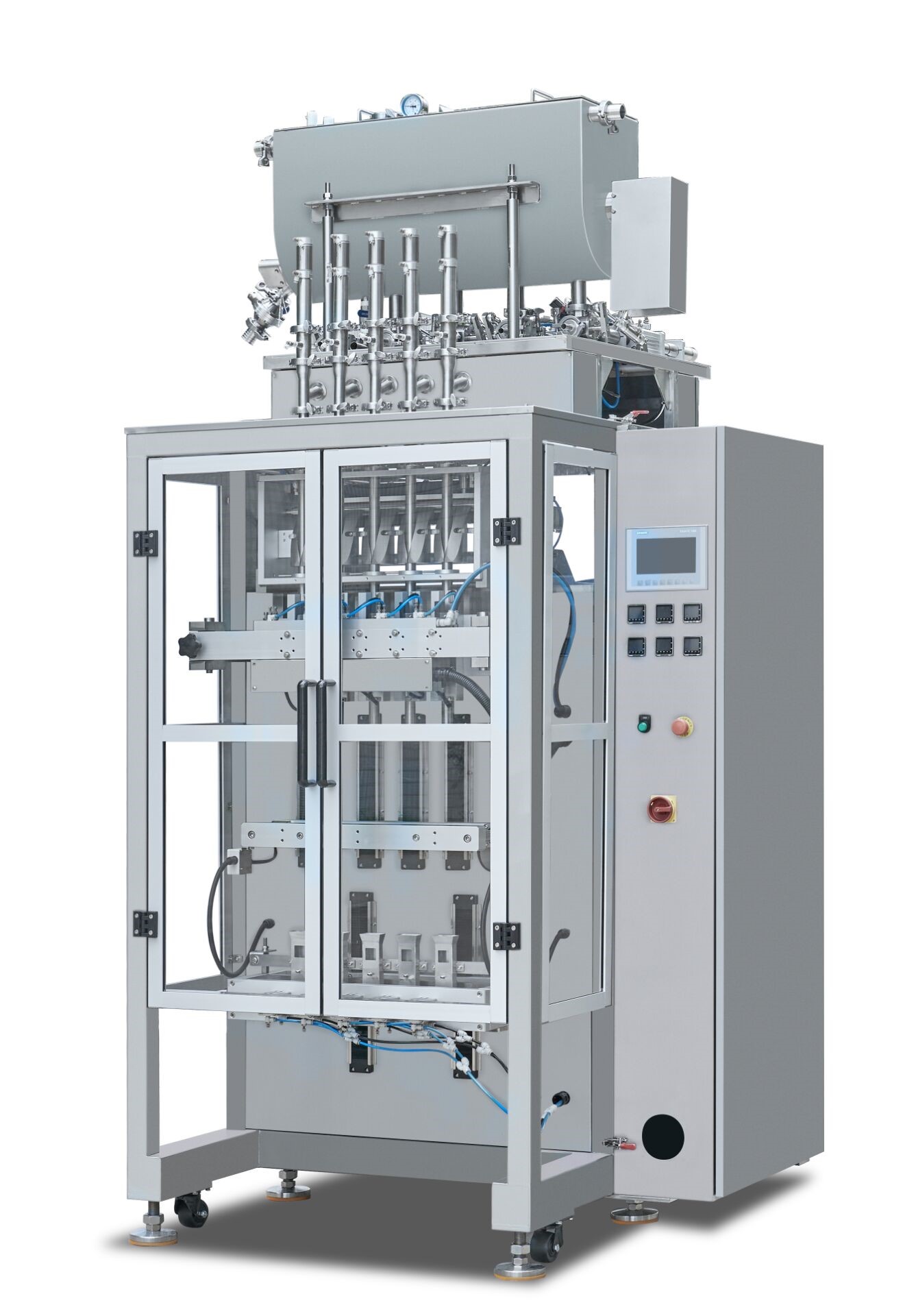

Multi row sachet back sealing machine for liquid powder

Multi-column VFFS filling machine for protein powder

Model | MLP-320 Sealing and cutting layers - Lanes and packaging materials | MLP-480 Sealing and cutting layers - Lanes and packaging materials | MLP-800 Sealing and cutting layers - Lanes and packaging materials |

Maximum film width | 320mm | 480mm | 800mm |

Bag size | Min width 16mm Length 60-120mm | Min width 16mm Length 80-180mm | Min width 16mm Length 80-180mm |

Sealing and cutting layers | A-one layer/B- two layer /C- three layer | ||

Lanes | 3-12(Select the proper machine model according to the bag width, the total film width calculated) | ||

Packaging materials | G - Granule / P-Powder / L-Liquid | ||

Speed | (20-60)Cycles/min * Lanes (speed varies according to film material characteristics) | ||

Film | Aluminum foil film/Laminated film, etc | ||

Bag format | Back seal | ||

Cutting | Flat/Zig-Zag cut/Shape cut | ||

Air pressure | 0.6 mpa | ||

Voltage power | 220V 1PH 50HZ(Power varies by the lanes) | ||

1. Multi track coffee stick packaging filling machine can handle multi-line powder product weighing, measuring, dispensing, sealing, cutting, and packing tasks.

2. Heat sealing film pulling is driven by motor,ensures smooth operation and accuracy.

3. Sensitive photosensitive sensor for precise color code tracking.

4. The CNC-integrated bag maker makes sure that every film column is equally pressured and does not rip and run away.

5. After cutting, the film's edge is smooth and solid thanks to an advanced film dividing mechanism and an alloy cutting blade.

6. Film roll position can be modified by hand wheel on one-piece film release system.

7. Touch screens can be used to establish packaging parameters, and daily production and machine problems can also be tracked.

8. 304 stainless steel and aluminum alloy are made of materials that adhere to GMP standards, are durable, low maintenance cost.

9. The machine's posture and height can be changed thanks to its adjustable foot cups and universal wheels.

10. Good compatibility, automatic feeder and output conveyor are optional.

Cup fillers and screw feeders with vibrating hoppers are available for powder products.

You can decide whether to have a lobe pump, diaphragm pump, etc. for filling and a magnetic pump, gear pump, etc. for measuring when it comes to liquid beverages.

Multiline coffee powder pouch bag bagging machine is frequently used when it comes to packaging powder and liquids like instant coffee, protein powder, honey, medicine powder, tea powder, milk powder, flavoring powder, etc. Other types of sealing include the back seal and the four-side seal.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved