Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

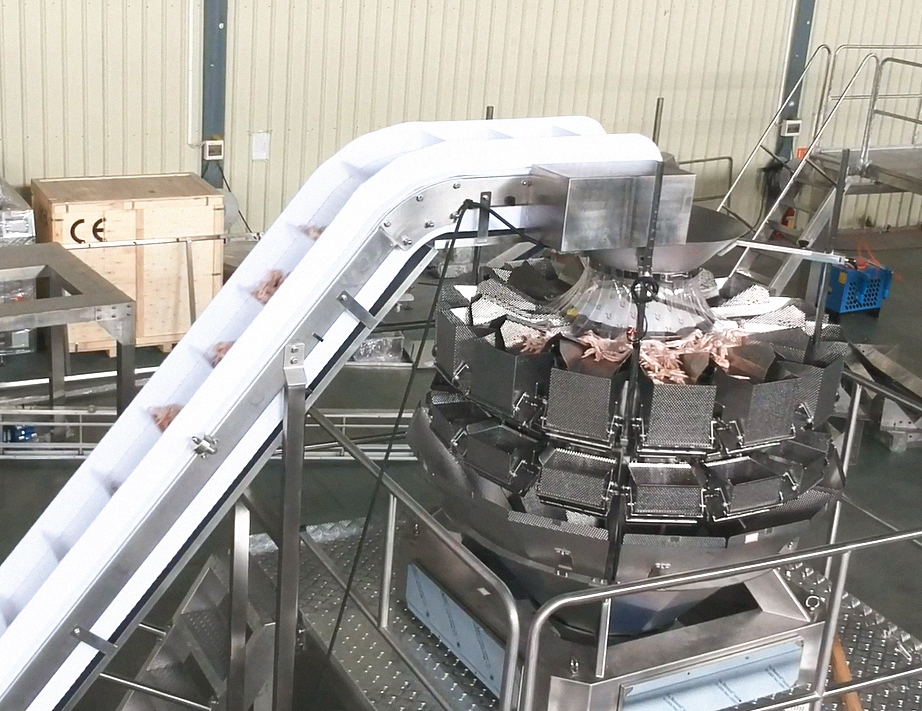

A frozen chicken claw packaging system by Smart Weigh Pack was designed to have accuracy of up to 3g and a speed of 40–45 trays per minute (40–45 x 60 minutes x 8 hours = 19,200–21,600 trays/day). Additionally, top-down pressing is used to minimize the space taken up by chicken claws while maintaining high sealing quality.

We advise you to select a tray packing line that consists of a two-layer linear feeding pan and a 3L 24 head multi-head weigher.

The multihead weighing machine has a flexible structural composition, the parts that come into direct contact with the food are IP65 waterproof, and the hopper can be disassembled directly and manually, eliminating the drawback that residual impurities are difficult to clean and raising hygiene standards. The speed and temperature during the operation of the chicken feet packing line can also be adjusted.

To ensure hygienic operations, all weighing and packing equipment made by Smart Weigh is constructed from food grade SUS304 stainless steel safety material.

Depending on your specific demands, we may offer you either cheap semi-automated packaging lines or fully automatic packing lines with a high level of efficiency.

1. Depending on their needs, customers can select a large inclination elevator or Z conveyor.

2. 10/14/16/24 head weighers can be chosen based on the material's size and accuracy requirements.

3. The capacity of the hopper may be adjusted as 1.6L/2.5L/3L, double door/single door, and the timing hopper can be utilized selectively. The hopper can also have a dimple plate, Teflon coating, or a smooth surface according on the material's viscosity and fluidity.

4. To increase packaging efficiency, a one point two/one point four device can be chosen.

5. Depending on the size of the pallet or case, the horizontal conveyor's width can be adjusted.

Product | chicken feet |

Target weight | 2kg |

Accuracy | +-3g |

Package Way | tray |

Speed | 40-45 trays per minute |

Vibrating feeder allows chicken claws to access the huge inclined conveyor.

The multi-head weigher receives the chicken claws from the huge inclined conveyor.

The product can be discharged from the discharge chute after multi-head weigher performs high accuracy weighing and metering.

A one-point-four device automatically fills four portions at a time.

The output conveyor transports the chicken claws after they have been portioned off into pallets.

1. Packaging method: Tray/carton/semi-automatic options

2. Packing size: flexible configuration according to customer needs.

3. Packaging range: frozen chicken knuckles, seafood, meatballs, fresh vegetables, fruits, fast food box lunch, etc.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved