Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

A customer in the United States ordered a ready-to-eat meal packaging line from Smart Weigh. They said the fully automated fast food packaging system works well to provide weighing solutions for oily, sticky, multi-ingredient mixtures, and the machine operates well in wet, acidic and alkaline environments.

Smart Weigh has developed a tray weighing and packaging machine for ready-to-eat food products that can package approximately 25 trays per minute(25x 60 minutes x 8 hours = 12,000 trays/day), with automatic weighing, empty tray detection, tray loading, filling, vacuum gas flushing, roll film cutting, sealing, discharging and waste collection.

Smart Weigh offers you several high precision multihead weighers with screw feeders for weighing various mixed ingredients in packaged boxed meals.

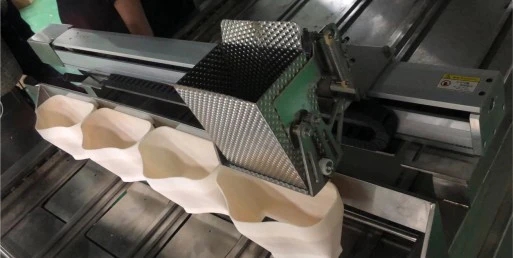

We can design for you discharge chutes with specific angles, side scraping hoppers with patterned surfaces, Teflon-coated weighers, etc., which can prevent materials from sticking and speed up the movement of oily and sticky materials. On the other hand, our weighing machines are made of stainless steel food grade material to ensure safety and hygiene, IP65 waterproof rating for cleaning.

Servo motor drive, smooth operation and precise filling positioning can reduce food waste. Intelligent detection of empty trays can prevent incorrect filling and sealing, saving machine cleaning time. Long service life of electrical and pneumatic components and low maintenance costs.

A tray filling line can be operated by just two people. One pallet filling line may fill a variety of materials simultaneously while taking up less room.

In accordance with the size of the tray, the tray dispenser's height and width can be freely adjusted. It is also highly waterproof, simple to setup, disassemble, and clean. Utilizing technology for spiral separation and pressing, it can minimize squeezing and deforming of the tray, and the vacuum suction cup can precisely guide the tray into the mold.

Customers can choose a round hopper or a rectangular filling equipment for automatic filling of trays of various shapes. You can also choose one part four splice device to increase filling efficiency.

It is simple to adjust speed and accuracy, lessen weighing error, and achieve production intelligence thanks to the color touch screen.

The food can be treated with the vacuum gas flushing system in a harmless manner to extend its shelf life. Cutting roll film and firm heat sealing, waste film collecting, and reduced material waste are all available.

Model | SW-2R-VG | SW-4R-VG |

Voltage | 3P380v/50hz | |

Power | 3.2kW | 5.5kW |

Sealing temperature | 0-300℃ | |

Tray size | L:W≤ 240*150mm H≤55mm | |

Sealing Material | PET/PE, PP, Aluminum foil, Paper/PET/PE | |

Capacity | 700 trays/h | 1400 trays/h |

Replacement rate | ≥95% | |

Intake pressure | 0.6-0.8Mpa | |

G.W | 680kg | 960kg |

Dimensions | 2200×1000×1800mm | 2800×1300×1800mm |

Suitable for trays of various sizes, materials, and shapes, including rectangular trays, plastic bowls, etc.

Cooked foods such sticky rice, meat, noodles, pickles, etc. can be packaged using a linear tray filling and sealing packaging system.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved