Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Smart Weigh was contacted by a customer from New Zealand who needed a solution to weigh and measure mixed ingredients. Finding an appropriate intelligent weighing machine was important to him since he primarily manufactures mixed flavors of snacks with minute particles and irregular forms, which made manual sorting and weighing challenging.

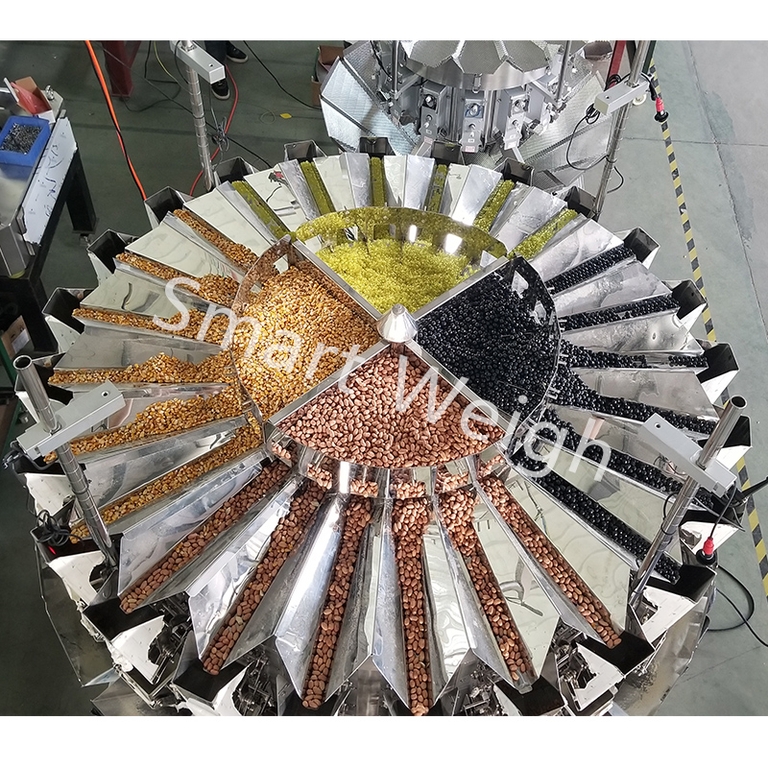

Smart Weigh Pack recommended a new fully automatic mixed granules weighing and packaging system, capable of bagging an average of 45 bags per minute (45 x 60 minutes x 8 hours = 21,600 bags/day). High accuracy 24-head multihead weigher that can weigh up to 6 flavors combined at once and manage the accuracy of the final mixture to within 1 gram by altering the ratio of individual materials. With a memory hopper function, it can work as a 48-head.

Products | Example of weighing proportion | ||

Almonds | 20% | 10% | 25% |

Cashews | 10% | 20% | 15% |

Raisins | 20% | 15% | 10% |

Strawberries | 20% | 15% | 10% |

Cherries | 15% | 25% | 20% |

Peanuts | 15% | 15% | 20% |

Total | 100% | 100% | 100% |

3 weighing mode for selection: Mixture, twin & high speed weighing with one bagger;

Discharge angle design into vertically to connect with twin bagger, less collision & higher speed;

Select and check different program on running menu without password, user-friendly;

One touch screen on twin weigher, easy operation;

Central load cell for ancillary feed system, suitable for different product;

All food contact parts can be took out for cleaning without tool;

Check weigher signal feedback to auto adjust weighing in better accuracy;

PC monitor for all weigher working condition by lane, easy for production management;

Optional CAN bus protocol for higher speed and stable performance;

Application | Daily Mixture Nuts (25-50g/bag) | |

Speed | Up to 45 bags/min ( 45 x 60 minutes x 8 hours = 21,600bags/day) | |

Tolerance | +1.0g | |

No. | Machine | Function |

1 | Z Bucket Conveyor | 4-6 pcs to feeding various kinds of nuts |

2 | 24 head multihead weigher | Auto weighing 4-6 kinds of nuts and filling together |

3 | Supporting Platform | Support 24 head on top of bagger |

4 | Premade pouch packing machine or Vertical Form Fill Seal Machine or Canning Seal Machine | Packing by Doypack or Pillow Bag or Jar/Bottle |

5 | Check Weigher & Metal Detector | Detecting weight and metal in bag |

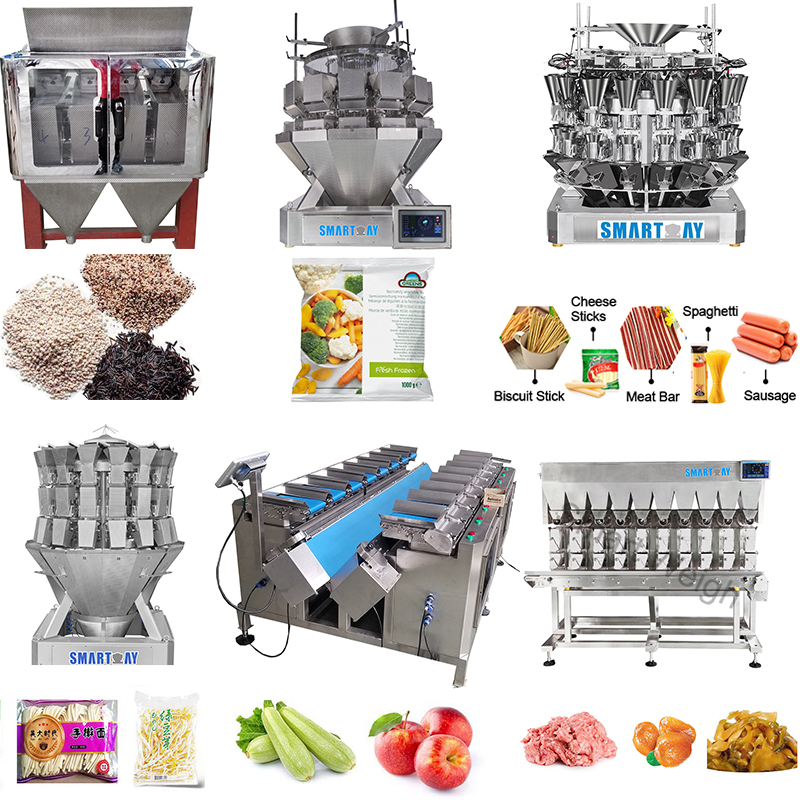

To accommodate various packaging requirements of customers, the weigher we provide can be integrated with vertical packaging machines, rotary packaging machines, tray sealing machines, and bottle packaging lines. The vertical form fill seal machine is mostly used for gusset, pillow, and linking bags. The pre-made bag packaging machine is typically used for flat bags, doypack, zipper bags, stand-up pouches, shaped bags, etc.

24 heads weigher is primarily used to weigh bulk mixed granular products such biscuits, grains, dried fruits, nuts, gummy candies, nuts, etc.

Smart Weigh creates a variety of weighers, such as linear weighers for weighing small granules or powder at a lower cost, salad multi-head weighers for weighing frozen vegetables, chopstick weighers for weighing stick-shaped products that fit vertically into the bag, noodle weighers for weighing long soft sticky materials, linear combination belt weighers for weighing large fragile fruits and vegetables, and screw meat weighers for weighing sticky materials like fried rice, pickles, etc.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved