Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

For perishable meat products, vegetables that are susceptible to moisture, using vacuum packaging machine is an ideal solution.

The bags have exquisite appearance and various styles, you can freely choose multi-layer composite film, single-layer polyethylene, polypropylene, plastic bags, paper bags, zipper bags, stand-up bags, flat bags, doypack, etc. The high sealing quality can effectively improve the added value of the products.

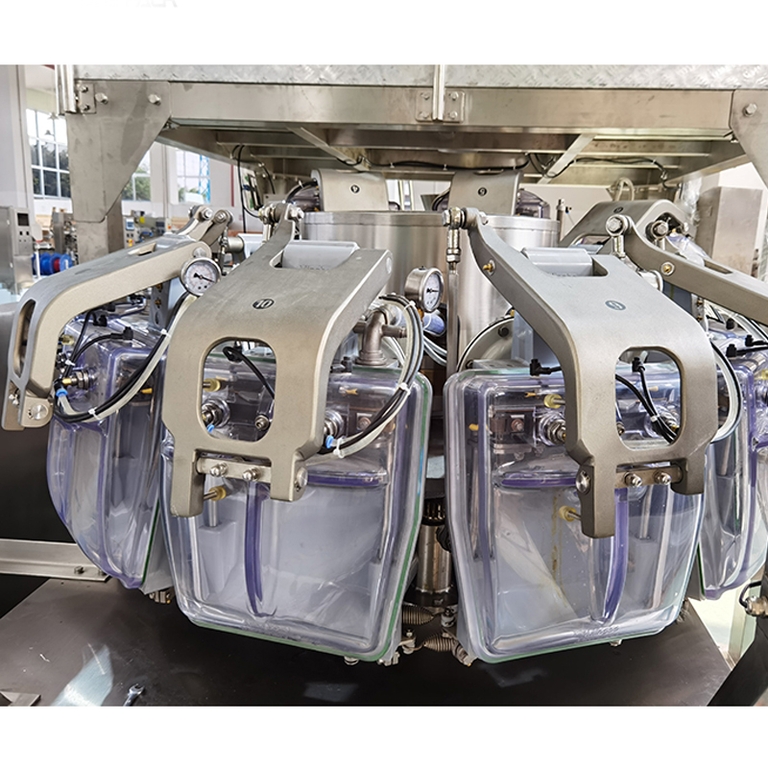

Packaging machine for premade bags is an automated equipment for picking up, opening, coding, filling and sealing of premade bags. The vacuum premade bag packing machine, on the basis of the premade pouch packaging machine, adding a specially designed rotary vacuum system. After completing automatic filling, instead of sealing directly, the bags are placed inside the vacuum system by the rotating device for vacuuming before sealing and output. The vacuum sealer preformed bag packaging machine consists of bag release and bag feeding device, bag clamps, filling equipment, vacuum chamber, finished material conveyor, human-machine interface touch screen, etc.

The production efficiency of rotary vacuum packaging machine is much higher than thermoforming vacuum packaging technology. The economic rotary vacuum packaging machine is suitable for high-speed vacuum sachet packaging, capable of fast packaging at a speed of 60 packs per minute. The rotary vacuum packaging machine can make the bags reach 99% vacuum, so that perishable food can be kept fresh for a long time. The eight-station rotary vacuum machine is compact and reduces excess space occupation.

Item | SW-120 | SW-160 | SW-200 |

Packing Speed | Max 60 bags / min | ||

Bag size | L80-180mm | L80-240mm | L150-300mm |

W50-120mm | W80-160mm | W120-200mm | |

Bag Type | Premade Four-side sealed bag, Paper bag, Laminated bag, etc. | ||

Weighing Range | 10g~200g | 15~500g | 20g~1kg |

Measurement Accuracy | ≤±0.5 ~ 1.0%,depend on the measurement equipment and materials | ||

Maximum bag width | 120mm | 160mm | 200mm |

Gas consumption | 0.8Mpa 0.3m³/min | ||

Total power/ voltage | 10kw 380v 50/60hz | 10kw 380v 50/60hz | 10kw 380v 50/60hz |

Air compressor | Not less than 1 CBM | ||

Dimension | L2100*W1400 *H1700mm | L2500*W1550 *H1700mm | L2600*W1900* H1700mm |

Machine Weight | 2000kg | 2200kg | 3000kg |

1、Automatic vacuum packaging machine adopts oil-free vacuum pump to guarantee the hygiene of the production process.

2、The parts in contact with food are made of SUS304 stainless steel food grade material, safe and pollution-free.

3、The width of the bag clamping device can be flexibly adjusted to adapt to different sizes and shapes of bags.

4、Automatically check for no bag or open bag error to reduce material waste.

5、Intelligent temperature control function to achieve high quality heat sealing.

6、Intelligent electronics touch screen with multi-language interface, which can operate the machine by setting relevant parameters.

7、When there is abnormal air pressure or heating tube failure, alarm will be prompted and timely feedback on which faults occur, which guarantees the safety of the production process.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved