Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

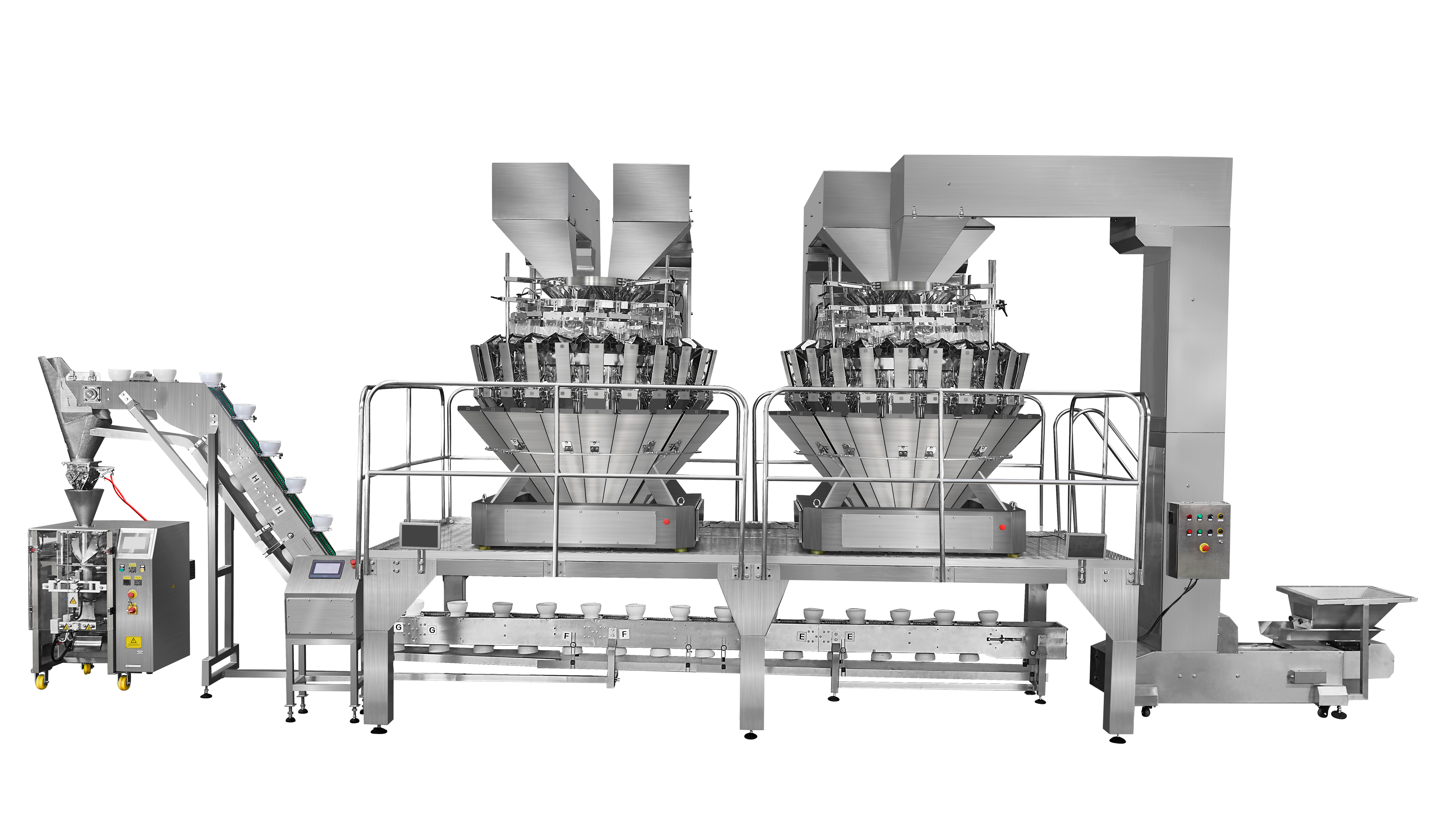

A customer from Malaysia approached Smart Weigh for a solution that would automatically weigh and package a mixture of materials to improve efficiency while saving as much cost and space as possible. Then Smart Weigh recommended Vertical Mix Packaging System.

Suitable for mixed granular materials packaging: such as ginger shredded red dates packets, flower tea, health tea, soup packets, etc.

A variety of granular materials are mixed, such as flakes red dates, filaments ginger, etc., requiring precise control of the ratio and weight of each material.

Multiple weighing machines and multiple packing machines are more space consuming and not conducive to small scale shops to increase production.

l Multiple multi-head weighers weigh different materials to ensure accurate weighing of each material.

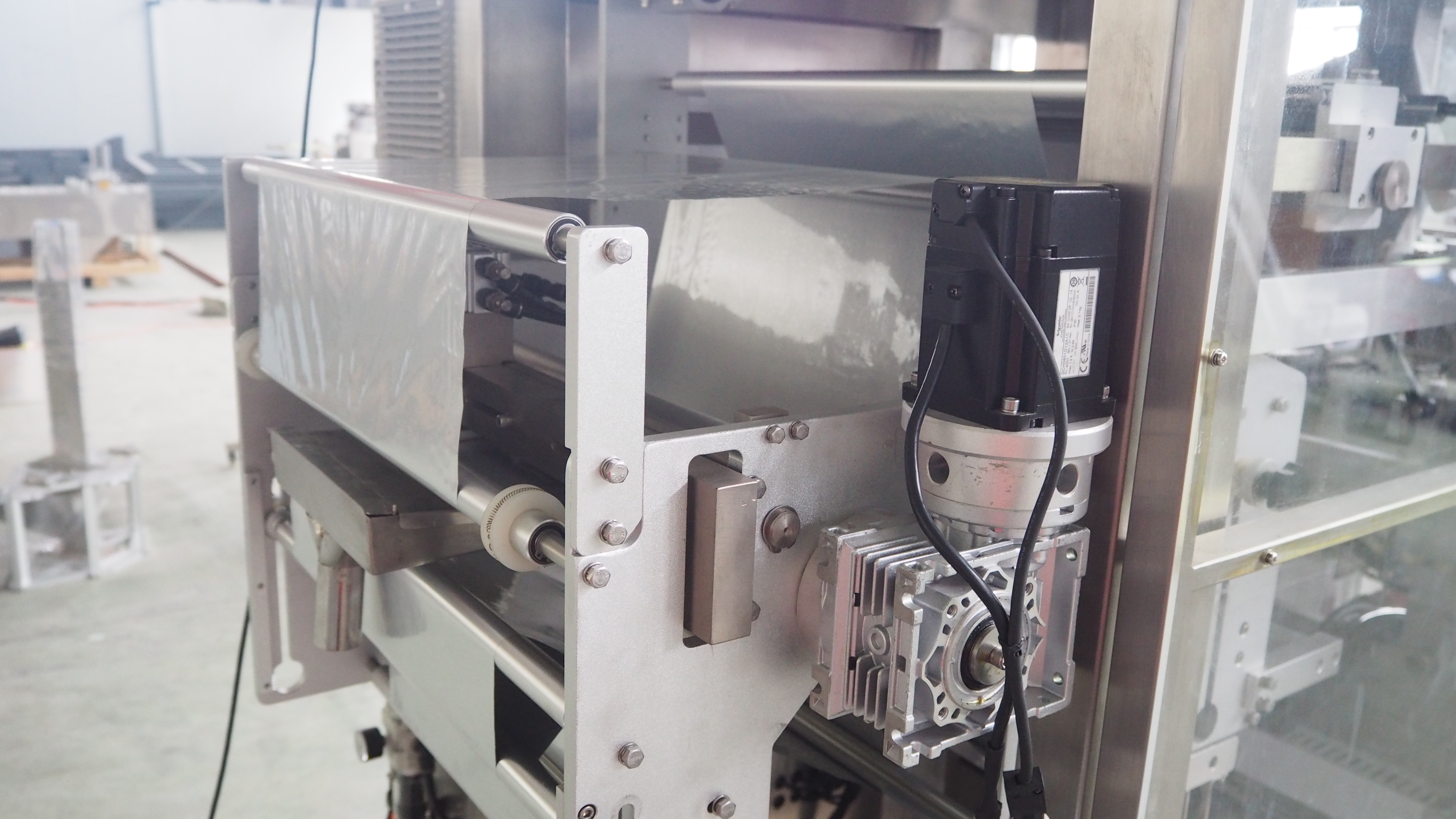

l Multiple multihead weighers are connected to a vertical packaging machine, which saves space to the greatest extent and realizes the packaging of mixed materials.

l The weighed material is transported to the VFFS packing machine through secondary lifting, which is suitable for lower workshops.

Model | SW-PL1 |

System | Multihead weigher vertical packing system |

Application | Granular product |

Weigh range | 10-1000g (10 head); 10-2000g (14 head) |

Accuracy | ±0.1-1.5 g |

Speed | 30-50 bags/min (normal) 50-70 bags/min (twin servo) 70-120 bags/min (continuous sealing) |

Bag size | Width=50-500mm, length=80-800mm (Depends on packing machine model) |

Bag style | Pillow bag, gusset bag, quad-sealed bag |

Bag material | Laminated or PE film |

Weighing method | Load cell |

Control penal | 7" or 10" touch screen |

Power supply | 5.95 KW |

Air consumption | 1.5m3/min |

Voltage | 220V/50HZ or 60HZ, single phase |

Packing size | 20”or 40”container |

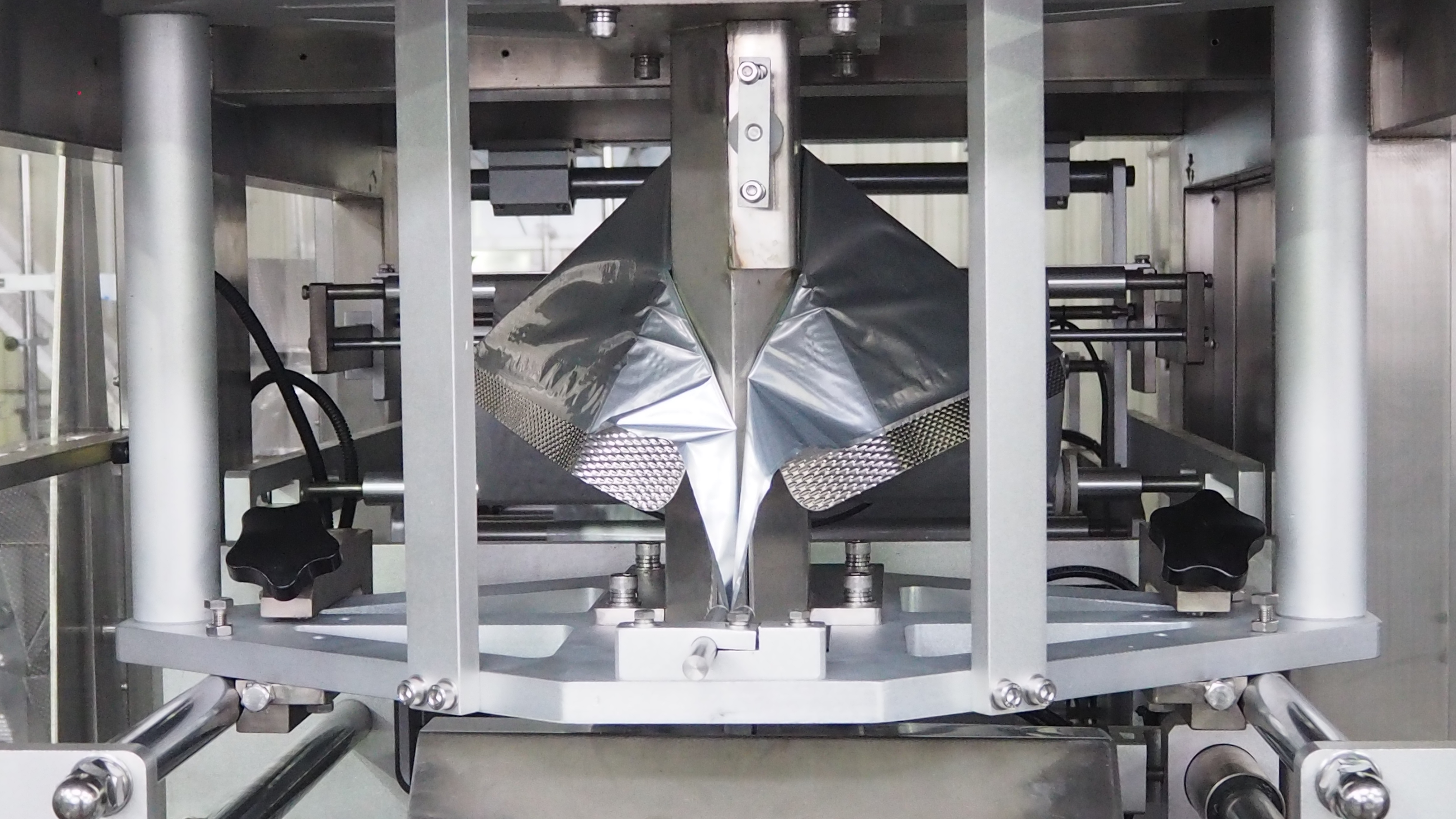

ü PLC control system, more stable and accuracy output signal, bag-making, measuring, filling, printing, cutting, finished in one operation;

ü Separate circuit boxes for pneumatic and power control. Low noise, and more stable;

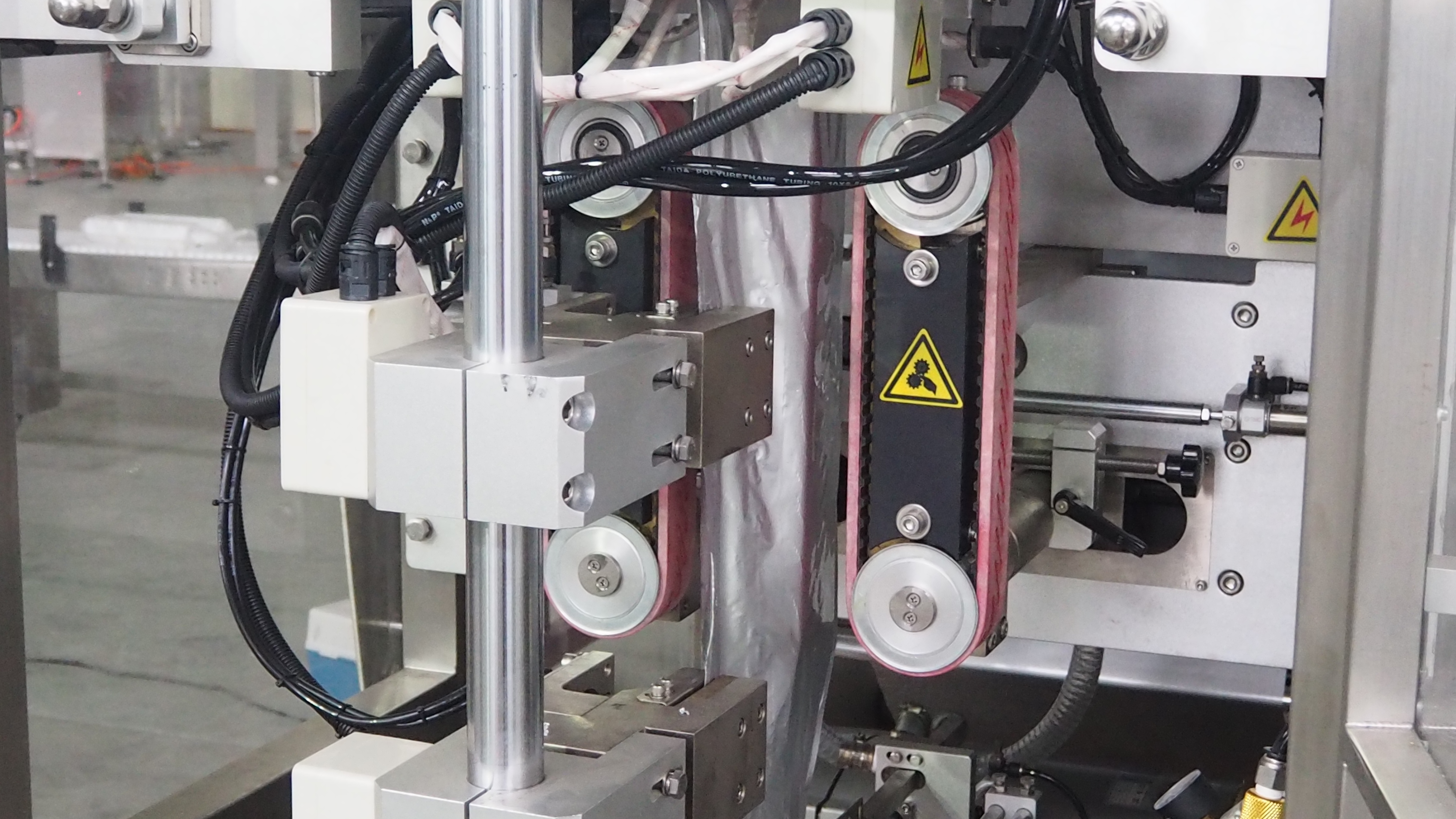

ü Film-pulling with servo motor for precision, pulling belt with cover to protect moisture;

ü Open door alarm and stop machine running in any condition for safety regulation;

ü Film centering automatically is available (Optional);

ü only control touch screen to adjust bag deviation. Simple operation;

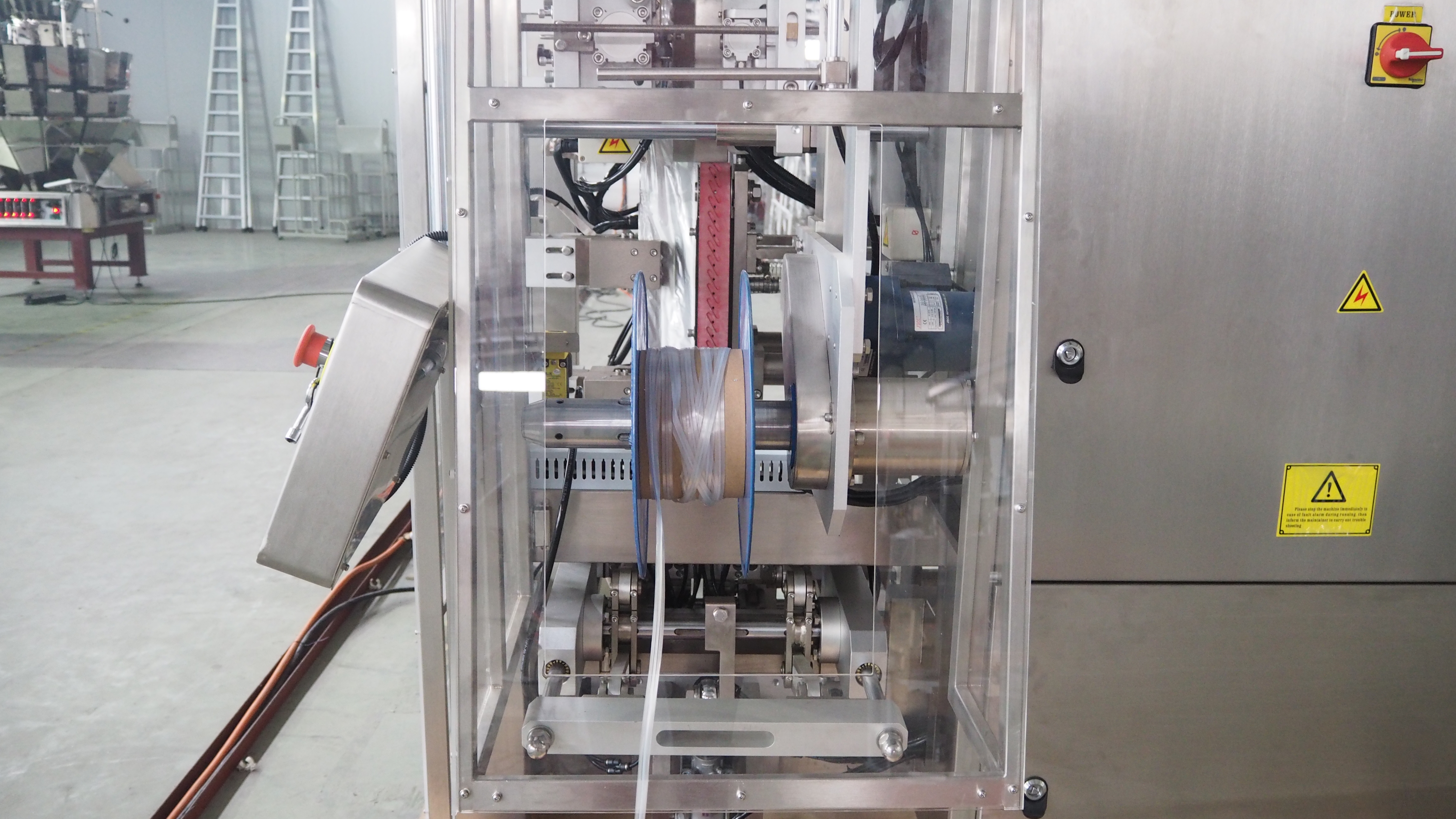

ü Film in roller can be locked and unlocked by air, convenient while change film;

1. Pour the material into the vibrating feeder, and then lift it to the top of the multihead weigher to add material;

2. The computerized combination weigher completes the automatic weighing according to the set weight;

3. The set weight of the product is dropped into the packing machine, and the packaging film is finished forming and sealing;

4. The bag enters the metal detector, and if there contains any mental, it will give the signal to the check weigher, and then the product will be rejected when it enters.

5. No metal bags into the check weigher, overweight or over-light will be rejected to the other side, qualified products into the rotary table;

6. The workers will load the finished bags into cartons from the top of the rotary table;

The qualification of the manufacturer. It includes the awareness of the company、the ability of researching and developing、customer quantities and certificates.

The weighing range of multi-head weigher packing machine. There are 1~100 grams, 10~1000 grams, 100~5000 grams, 100~10000grams, the weighing accuracy depends on the weigher weight range. If you choose 100-5000 grams range to weigh 200 grams’ products, the accuracy will be bigger. But you need to choose the weigher packing machine on the basis of the product volume.

The speed of the packing machine. The speed is inversely correlated with its accuracy. The higher speed is; the worse the accuracy is. For semi-automatic weighing packing machine, it would be better to take a worker’s capacity into consideration. It’s the best choice for getting a packing machine solution from Smart Weigh Packaging Machinery, you will get a suitable and accurate quotation with electrical configuration.

The complexity of operating the machine. The operation should be an important point when selecting the multihead weigher packing machine supplier. The worker can operate and maintain it easily in daily production, save more time.

The after-sales service. It includes machine installation, machine debugging, training, maintenance and etc. Smart Weigh Packaging Machinery has a complete after-sales and before-sales service.

Other conditions include but not limited to machine appearance, the value of money, free spare parts, transportation, delivery, payment terms and etc.

Guangdong Smart weigh pack integrates food processing and packaging solutions with more than 1000 systems installed in more than 50 countries. The company offers a comprehensive range of weighing and packaging machine products, including noodle weighers, salad weighers, nut blending weighers, legal cannabis weighers, meat weighers, stick shape multihead weighers, vertical packaging machines, premade bag packaging machines, tray sealing machines, bottle filling machines, etc.

Invested 5 million RMB on March 15, 2012.

Factory area increased from 1500 square meters to 4500 square meters.

Certificate of High and New Technology Enterprise

City-level industrial enterprise

Passed CE certification

7 patents, with experienced technical team, software team and overseas service team.

Attend about 5 exhibitions every year and visit customers frequently for face-to-face negotiation.

In an era of the credibility crisis, trust needs to be earned. That is why I would like to take this chance and walk you through the journey of our past 6 years, That is why I would like to take this chance and walk you through the journey of our past 6 years, hoping to draw a clear picture of who this Smart Weigh, also your would-be business partner is.

How can you meet our requirements and needs well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

How can you ensure you will send us the machine after the balance paid?

We are a factory with business license and certificate. If that is not enough, we can make the deal through L/C payment to guarantee your money.

What about your payment?

T/T by bank account directly

L/C at sight

How can we check your machine quality after we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved