Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

The packaging machines have moved to their automation processing pretty quickly. All machines these days have a swift hand and work automatically, which has significantly made business far easier and production much more efficient.

However, in between all this quick and efficient automation, machines require maintenance too. Similar is the case for powder packaging machines. Here are some simple steps to maintain it if you are a machine owner.

Ways to Maintain a Powder Packaging Machine

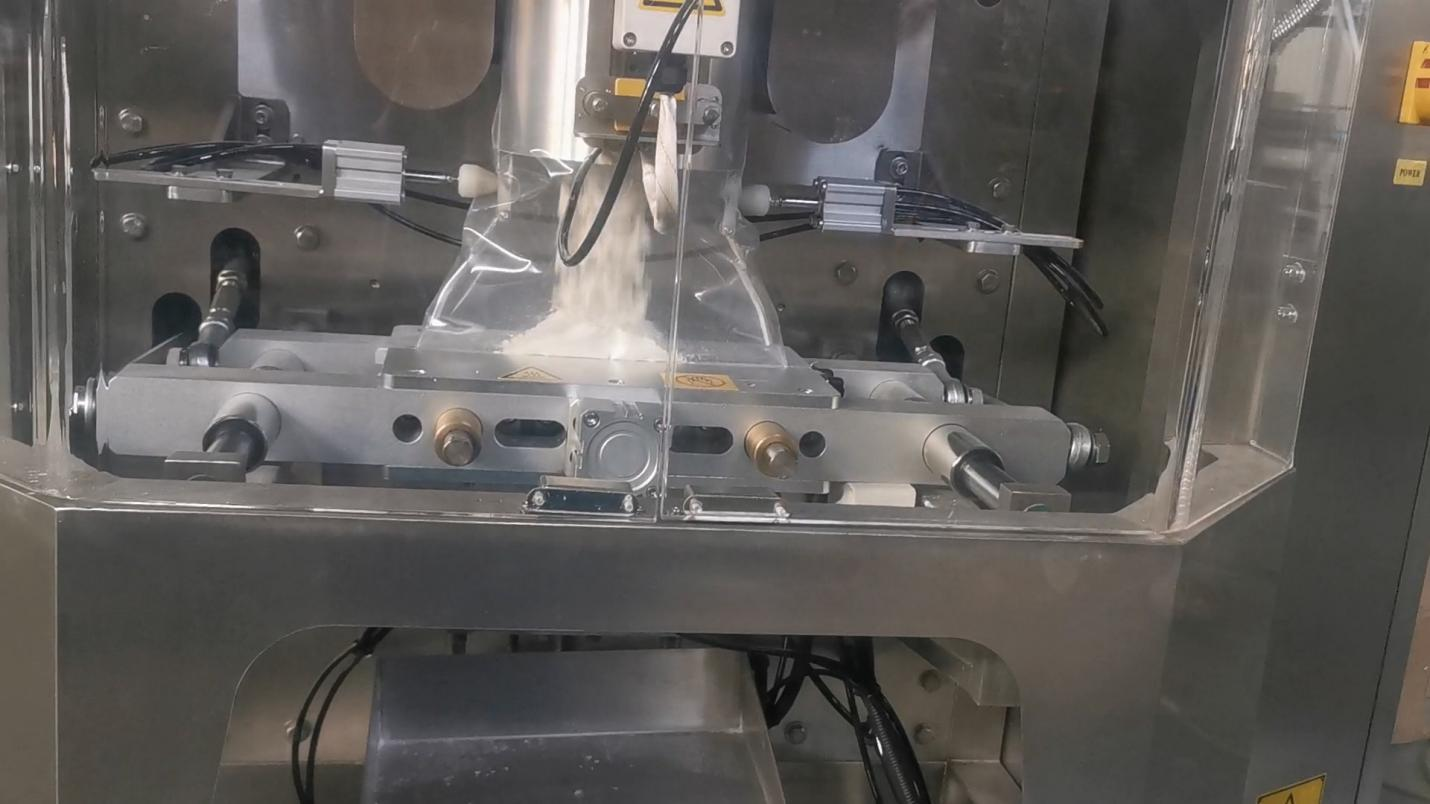

The powder packaging machine is one of the market's most efficient and friendly operable machines, with the perfect essence of quality and finesse. However, regardless of how amazing it is, this machine requires some maintenance from time to time as well. Here are some efficient ways to maintain a powder packaging machine.

1. Oil Lubrication

All machines need a booster to work and glide their parts efficiently. For the powder packaging machine, this particular booster happens to be oil. Hence, oil lubrication will always be the first step when trying to service a powder packaging machine.

All gear meshing points, moving parts, and oil-bearing holes should thoroughly be lubricated with oil. Moreover, running of reducer without oil or lubrication is strictly prohibited.

When lubricating, ensure that the oil doesn't fall on the packing machine pulling belt. This can cause premature aging or slip on the belt when making bags.

2. Clean Regularly

Another aspect of maintaining your powder packaging machine is cleaning it regularly. After the operation shuts down and the machine turns off, the first step should always be to clean the metering part and the heat sealing machine.

The main reason for thoroughly cleaning the heat sealing machine is to ensure that the packaging products' sealing lines are clear. The cleaning of the turntable and the discharging gate is also essential.

It is advisable to look into the control box and clean its dust in order to avoid any unforeseen short circuits or poor contact with other electrical devices.

3. Maintenance of Machine

Once lubricated and cleaned, overall survey maintenance is also essential. The powder packaging machine is one of the most efficient working machinery in the food and beverage world and holds significant importance. Hence, its manufacture is top-notch and consists of many different pieces and bolts all joined together to form one monstrous masterpiece in the form of this machine.

Therefore it is vital to check all screw and bolt placement and determine they are fitted in efficiently daily. Neglecting this maintenance checklist point can otherwise impact the overall working and rotation of the machinery.

The waterproof, corrosion resistant and rat-proof criteria should also be ticked off, and the screw should be loosened once the machine turns off.

4. Repair the Damaged Parts

Regular maintenance surveys will help you determine which parts of the machine need a repair on time. Hence, you won't encounter any operational problems due to maintenance neglect, which can cause you inefficiency in production.

Once you see any particular part in the machine that needs repairing, you can quickly get it done. Hence, the operational activities with the powder packaging machine will not only be carried out swiftly, but it will produce better products for your company and improve its efficiency and overall results.

So, keeping a thorough check and cleanliness of your machine is essential.

Smart Weigh – The Priority Choice to Purchase an Efficient Powder Packaging Machine

Taking care of high-end machinery is a huge task, and why shouldn't it be? Considering they aren't a dollar worth of product at your near target and cost a hefty amount of money, it is only natural that you will give it the maintenance it deserves.

We hope this article was sufficient to remove your jitters about how to maintain a powder packaging machine. So, if that is out of the way, and you are planning on buying this great machinery, look no further than Smart Weigh.

The company has been operating for years and has manufactured exceptional quality machinery that is the best in the market. If you are searching for one, then checking out our rotary packing machine or VFFS packing machine is what you should opt for.

All our powder packaging machines are the easy to operate, high accuracy and easy for maintenance, and you won't regret buying them from us.

Author: Smartweigh–Multihead Weigher

Author: Smartweigh–Multihead Weigher Manufacturers

Author: Smartweigh–Linear Weigher

Author: Smartweigh–Linear Weigher Packing Machine

Author: Smartweigh–Multihead Weigher Packing Machine

Author: Smartweigh–Tray Denester

Author: Smartweigh–Clamshell Packing Machine

Author: Smartweigh–Combination Weigher

Author: Smartweigh–Doypack Packing Machine

Author: Smartweigh–Premade Bag Packing Machine

Author: Smartweigh–Rotary Packing Machine

Author: Smartweigh–Vertical Packaging Machine

Author: Smartweigh–VFFS Packing Machine

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved