Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

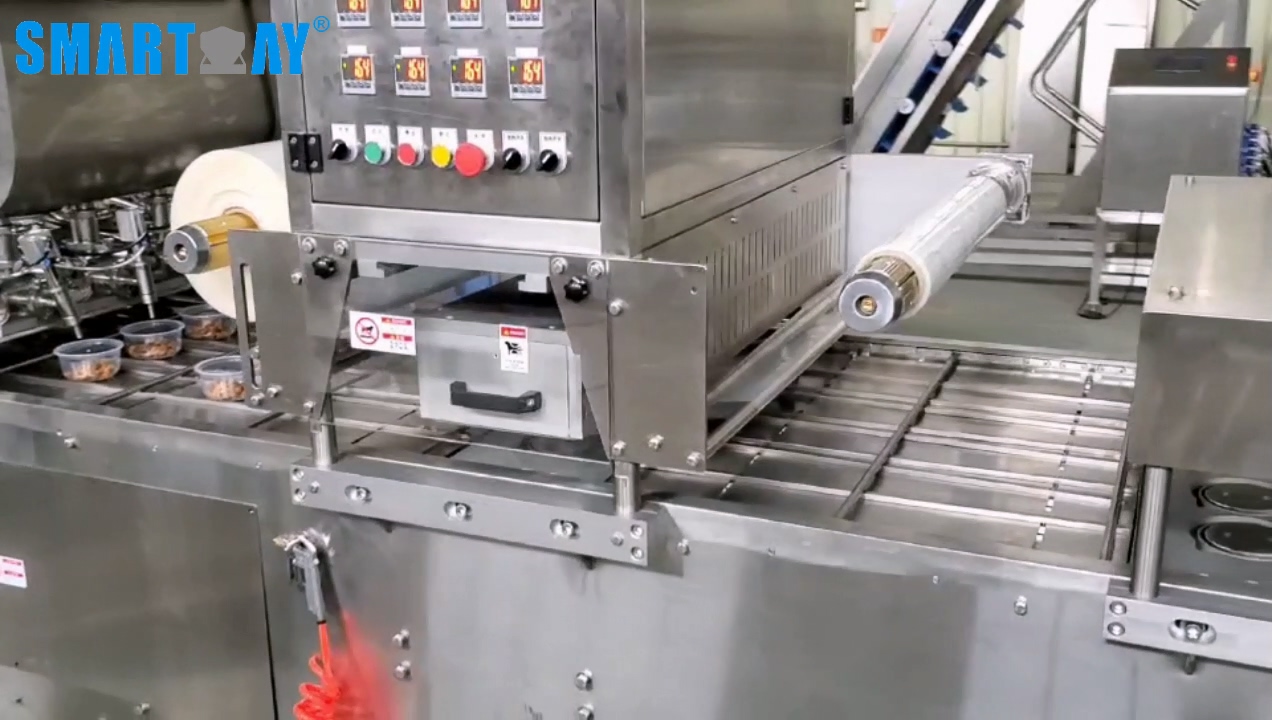

Sticky materials such as dried radish, corn kernels, cucumber shreds can be weighed, automatically filled into trays and sealed.

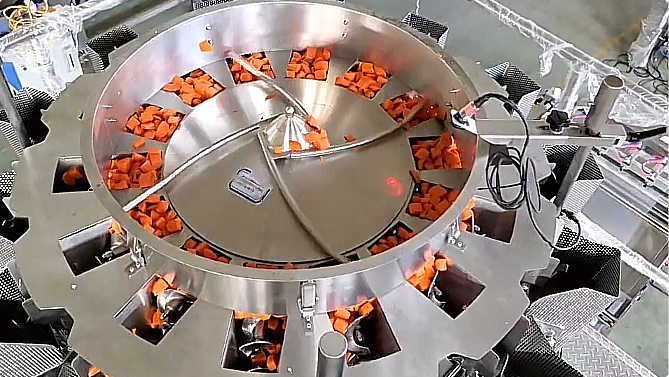

Central spiral screw rotating top cone distributes the sticky fresh material evenly to each hopper.

1. Screw feeder can improve the fluidity of the material and speed up the weighing.

2. Dimple surface hopper can prevent sticking and improve weighing accuracy.

3. Scrape gate hopper prevent product sticky on the hopper, ensure the accuracy.

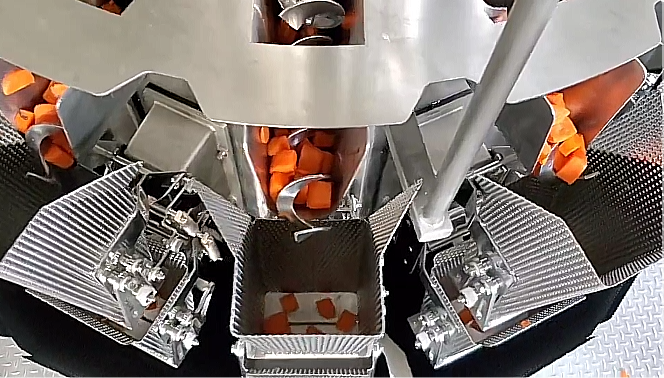

One point 4 divert can fill four trays per cycle, improving the filling efficiency. ( two divert, three divert or 6 divert are available)

Weighing range | 10-2000 grams |

Weigh bucket | 1.6L or 2.5L |

Weighing accuracy | + 0.1-1.5 grams |

Packing speed | 10-60 packs/min |

Package size | Length: 80-280mm Width: 80-250mm Height: 10-75mm |

Package shape of tray | Round shape or square shape trays |

Package material of tray | Plastic |

Control system | PLC with 7" touch screen |

Voltage | 220V, 50HZ/60HZ |

◪IP65 waterproof, use water cleaning directly, save time while cleaning;

◪Modular control system, more stability and lower maintenance fees;

◪Production records can be checked or download to PC;

◪Load cell or photo sensor checking to satisfy different requirements;

◪Preset stagger dump function to stop blockage;

◪Refer to product features, select automatic or manual adjust feeding amplitude;

◪Food contact parts disassembling without tools, which is easier to clean;

◪It can realize automatic conveying and filling of trays, and is suitable for trays of various sizes, shapes and materials.

◪The tray feeding belt can load more than 400 trays, reduce the times of feeding tray;

◪Different tray separate way to fit for different material's tray, rotary separate or insert separate type for option;

◪The horizontal conveyor after the filling station can keep the same distance between every tray.

.◪Strong compatibility, can be equipped with multiple filling devices, can automatically fill diced radish into trays, add soy sauce, etc.

Guangdong Smart weigh pack provides you with weighing and packaging solutions for food and non-food industries, with innovative technology and extensive project management experience, we have installed more than 1000 systems in more than 50 countries. Our products have qualification certificates, undergo strict quality inspection, and have low maintenance costs. We will combine customer needs to provide you with the most cost-effective packaging solutions. The company offers a comprehensive range of weighing and packaging machine products, including noodle weighers, large-capacity salad weighers, 24 heads weigher for mixture nuts , high-precision weighers for hemp, screw feeder weighers for meat, 16 heads stick shaped multi-head weighers, vertical packaging machines, premade bag packaging machines, tray sealing machines, bottle packing machine, etc.

Finally, we provide you with 24-hour online service and accept customized services according to your actual requirements. If you would like more details or a free quote, please contact us and we will give you useful advice on weighing and packaging equipment to boost your business.

How can we meet your requirements well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

How to pay?

T/T by bank account directly

L/C at sight

How can you check our machine quality?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved