Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Bag-in-bag weighing and packaging system produced by Smart Weigh is suitable for konjac cool, duck neck, chicken feet, spicy strips and other snack in vacuum pouches.

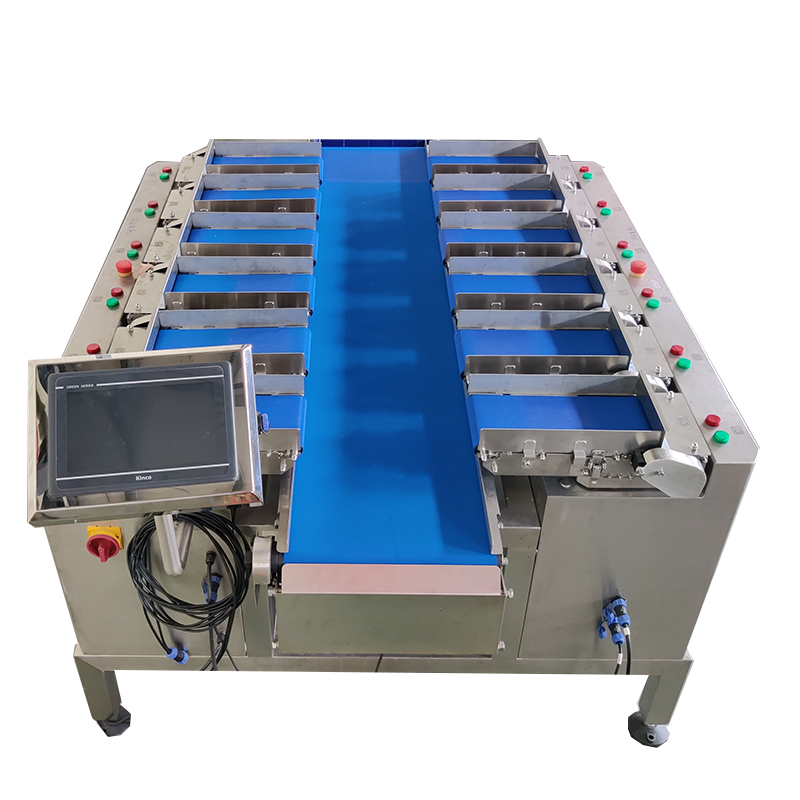

Today we mainly introduce vacuum bag-in-bag snack packaging line that integrates linear combination weigher and premade pouch packaging machine.

Function of Machine

The operation is simple. Conveyor belt can be disassembled manually.

l Belt weighing and delivery into package, only two procedure to get less scratch on products;

l Adjustable speed on all belts according to different product feature;

l 12 heads linear combination weigher adds an automatic zeroing procedure before weighing.

l Suitable to integrate with feeding conveyor & auto bagger in auto weighing and packing line;

l Suitable for many types of pre-made bags with good appearance and good sealing quality

l The whole process of bag picking, bag opening, coding, filling, sealing, forming and output can be completed at one time.

l The width of the bag can be adjusted by a motor, and the width of all clips can be adjusted by pressing the control button, which is easy to operate.

l Automatically check for no bag or open bag error, no filling, no sealing. Bags can be reused to avoid wasting packaging and raw materials.

l The operation is simple, it is matched with PLC touch screen and electric control system, and the man-machine interface is friendly.

l Air pressure abnormal shutdown, heater disconnection alarm.

l The parts in contact with the material are made of stainless steel.

Weighing capacity | 10-1500 g |

Accuracy | + 0.1-3.0 g |

Weigh Belt Size | 220L*120W mm |

Collating Belt Size | 1350L*165W |

Pouch material | Laminated film\PE\PP etc. |

Pouch pattern | Stand-up, spout, flat |

Pouch size | W:110-230 mm L:170-350 mm |

Max speed | 30 pouches /min |

Voltage | 380V 3phase 50HZ/60HZ |

Total power | 3KW |

Compress air | 0.6m3/min(supply by user) |

For bag in bag snack packaging, customers can also choose the following two types of multihead weighers.

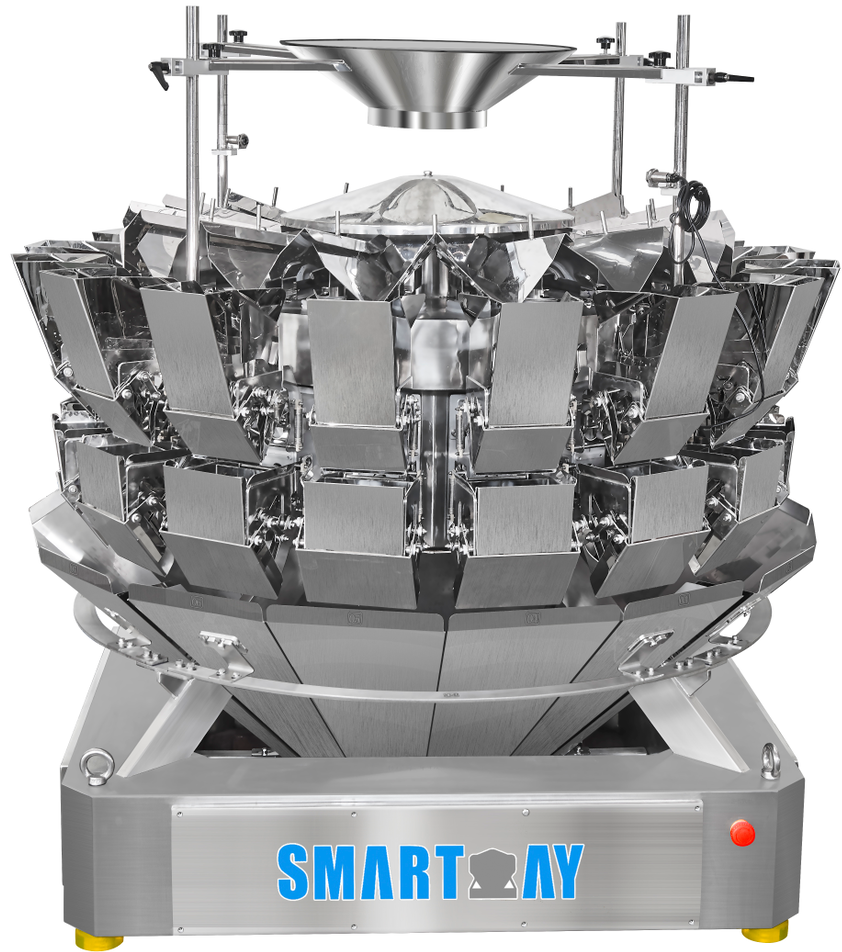

16 Heads Bag in Bag Weigher

ü Improved charging and dividing methods for secondary packaging of small bags, resulting in more even charging of individual hoppers, lifting speed and precision. The toggle structure is added to facilitate the control of the amount of material.

ü According to small bags counting into big bags, improve linear feeding system to make sure feed equally.

ü Update new program suitable to measure by counting and weighing together.

ü Design V type linear feeder pan to control feeding one by one.

ü Preset stagger dump function to stop blockage.

ü Refer to product features, select automatic or manual adjust feeding amplitude. The weighing device is located at the place of the main vibrating plate, the role of the weighing device is mainly for a quantitative control of the conveyor charging.

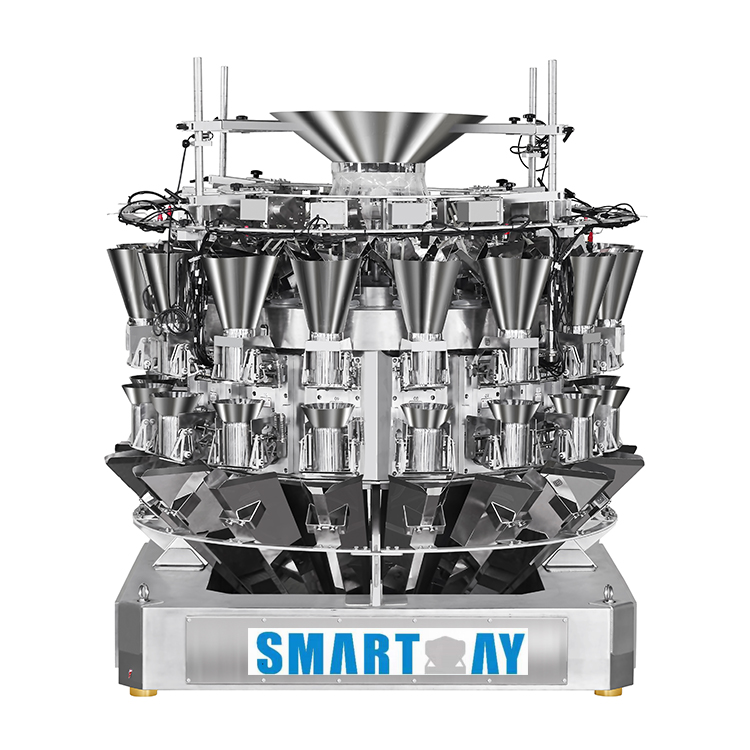

16 Head Stick Shape Multi-head Weigher

Suitable for stick-shaped foods: cookie sticks, chocolate bar, meat sticks, stick-pack coffee powder, etc.

ü The unique structure design prevents material accumulation and lowers the rate of packaging defective. The stick product will remain upright thanks to an unique bucket with a cylinder body,material entrapment is avoided by entering bags vertically. Maximum length that can be weighed is 200mm.

ü Automatic vibration frequency control ensures homogeneous and exact material dispersion.

ü Automatic zeroing to improve accuracy during operation.

Guangdong Smart weigh pack provides you with weighing and packaging solutions for food and non-food industries, with innovative technology and extensive project management experience, we have installed more than 1000 systems in more than 50 countries. Our products have qualification certificates, undergo strict quality inspection, and have low maintenance costs. We will combine customer needs to provide you with the most cost-effective packaging solutions. The company offers a comprehensive range of weighing and packaging machine products, including noodle weighers, large-capacity salad weighers, 24 heads weigher for mixture nuts , high-precision weighers for hemp, screw feeder weighers for meat, 16 heads stick shaped multi-head weighers, vertical packaging machines, premade bag packaging machines, tray sealing machines, bottle packing machine, etc.

Finally, we provide you with 24-hour online service and accept customized services according to your actual requirements. If you would like more details or a free quote, please contact us and we will give you useful advice on weighing and packaging equipment to boost your business.

How can we meet your requirements well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

How to pay?

T/T by bank account directly

L/C at sight

How can you check our machine quality?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by you own.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

How We Do It Meet And Define Global

Related Packaging Machinery

Contact us, we can give you professional food packaging turnkey solutions

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved