Application of a 14 Head Multihead Weigher in Commercial Settings

1. Introduction to Multihead Weighers

Multihead weigher serve rapid, highly accurate weight readings, which are required for precise yet effective product handling, and they have transformed commercial packaging. These apparatus, frequently esteemed for the effectiveness of their operation in the chemical, food, and pharmaceutical industries, convey a rapid and automated approach to measure and distribute items in specified amounts, hence enhancing the precision and quality of packaged products.14 head weighers are the most common in commercial settings due to their ability to combine speed and precision. This makes them suitable for large-scale, high-throughput applications.

A multihead weigher entails many weighing heads, each sporting its own load cell and weighing bucket, that work together to measure product weights fast and precisely. The method employed operates on a simple principle: each head weighs a little amount of product, and the machine's control system sums these weights to achieve the target weight as precisely as feasible. As the name indicates, a 14-head weigher has 14 weighing heads, allowing it to process a wide range of items with excellent speed, precision, and minimal product loss.

2. Working Mechanism of a 14-Head Multihead Weigher

✔Multihead Weighing Process

Each step in the 14 head multihead weigher's operation is carefully planned to guarantee quick and accurate measurement. The product is first supplied into the central dispersion system of the weigher, usually via a vibrating top cone that guarantees uniform product distribution into each of the 14 weighing heads. Each product portion's weight is recorded by the load cells, which are sensitive measuring sensors inside each head, as it enters the distribution channels.

The central processing unit-modular control system of the machine then determines which of the 14 heads' weight combinations will best accomplish the desired weight with the least amount of variation. The precision and speed of the multihead weigher are based on this combination computation. By choosing the best weight combination, the machine can swiftly adapt, resulting in great packing accuracy and less product waste. Because the modular control system continuously receives real-time data from each head, it is able to analyze a large number of weight combinations in milliseconds, enabling this degree of calculation.

✔Control Systems and Accuracy

High-precision measurements are made possible by the advanced sensors and modular control boards used in contemporary 14 head weighers. To make sure that every package is within permitted bounds, the sensors—especially the load cells—are extremely sensitive and able to identify even the slightest departures from the target weight.

The modular control board improves efficiency and dependability in addition to sensors. A single malfunctioning head won't stop the entire machine from working because of the modular board architecture, which is frequently found in expensive multihead weighers. This architecture makes maintenance easier while also increasing the system's accuracy and dependability. Factory automation systems can be coupled with the data collected by the modular control board to enable smooth communication and modification within the larger production line.

3. Benefits of Using a 14 Head Multihead Weigher

●Speed and Efficiency

The 14-head configuration's capacity to weigh goods rapidly and accurately is one of its main advantages. The equipment is able to process large amounts of product quickly since it can run all 14 heads at once. Increased throughput, which is a crucial component in sectors with frequent time-sensitive production schedules, results from this speed. By guaranteeing that every box contains the precise amount intended, weigher machines also provide a high degree of precision, reducing product giveaway.

●Versatility with Various Products

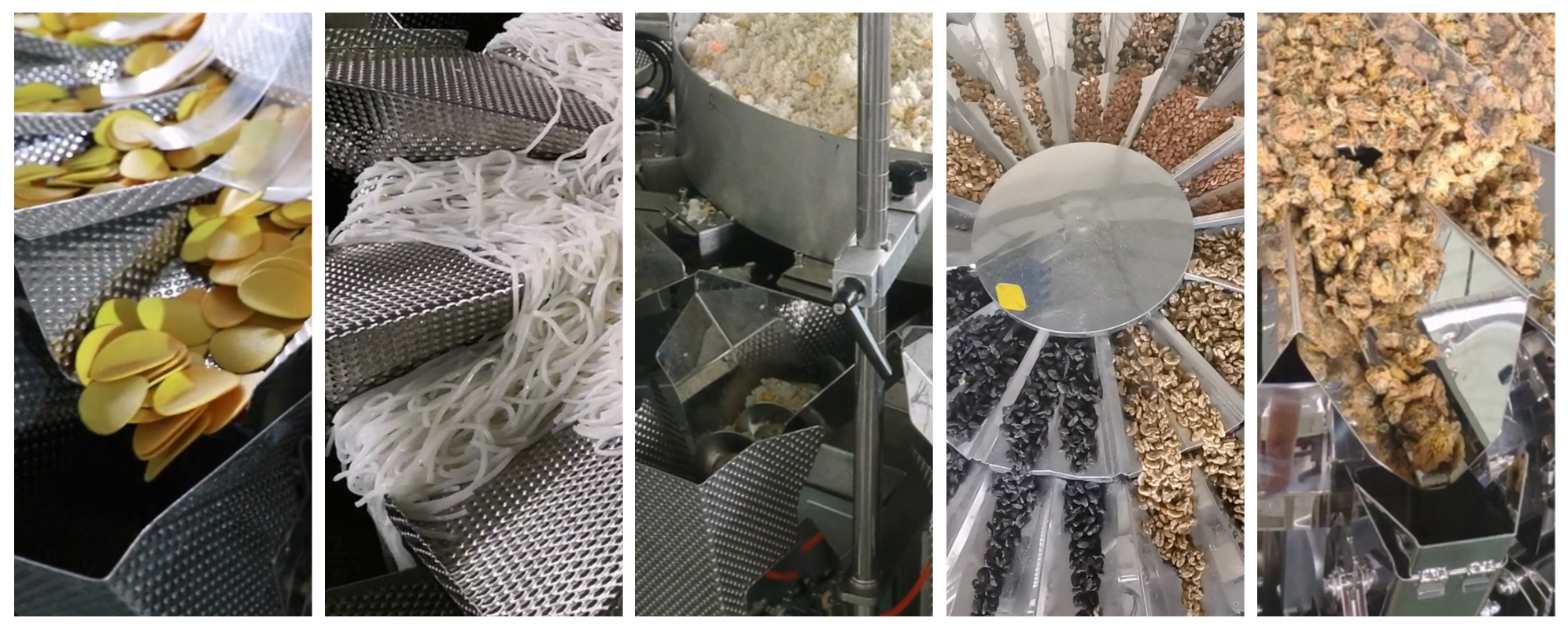

A variety of items with different weights, sizes, and consistencies can be handled by 14 head weighers. They can weigh anything from larger things like frozen meats or vegetables to delicate snack foods like chips in the food business, for instance. These weighers' programmable settings allow them to easily adjust to various product kinds without requiring a lot of downtime for recalibration.

●Minimizing Wastage and Overfill

Product giveaway, is an expensive packing problem, especially for companies with narrow profit margins. A 14 head multihead weigher greatly lowers the possibility of overfilling packages by offering accurate measurements. By lowering the quantity of merchandise that is needlessly given away, this precision lowers expenses while maintaining resources and increasing profitability. Furthermore, by reducing unnecessary packing and product loss, the accuracy of these devices reduces waste and promotes sustainable practices.

4. Industries Benefiting from Multihead Weighers

▶Food Industry

14 head multihead weighers constitute highly adjustable devices that efficiently weigh goods of various sizes and textures while causing minimum handling damage, making them very useful in the food business. These weighers are suitable for packing items that require accuracy and constancy in weight, such as confectionery, potato chips, pet food, fresh fruit, and nuts. To meet high food safety regulations, multihead weighers used in the food industry are often constructed with sanitary features and made of stainless steel to assure longevity and cleanliness.

▶Pharmaceutical & Chemical Industries

The amount given meticulousness is critical in the chemical and pharmaceutical industries, as even little changes can have catastrophic consequences. In order to guarantee uniformity in the completed product, weigher machines are used to precisely measure powders, granules, and fine particles. The 14 head weighers can handle sensitive chemical and pharmaceutical goods while adhering to high safety and accuracy standards owing to its precise control systems and adaptable architecture.

▶Bulk Retailers and Batching Applications

Multihead weighers are useful for batching applications and bulk sellers because they can efficiently handle enormous amounts of merchandise. Businesses that package bulk goods, like grains or seeds, for instance, can depend on these machines to package homogeneous quantities quickly, improving both product consistency and operational efficiency.

5. Key Features to Look for in a Multihead Weigher

◆Stainless Steel & Hygienic Designs

Hygienic design and the intake of stainless steel are required in sectors such as food processing and healthcare. Stainless steel is very durable, easy to clean, and corrosion resistant, making it suitable for food and chemical handling. Hygienic designs promote health and safety compliance by reducing contamination concerns and allowing for thorough cleaning.

◆Integration of Other Packaging Equipment

Multihead weighers are usually woven with other equipment, such as bagging systems, tray denesters, or bottling machines, to form fully automated packaging lines. The compatibility of a 14 head weigher with other packing equipment is critical. Continuous, coordinated workflows are enabled via seamless integration, which increases operational efficiency.

◆Programmable Settings and Recipe Storage

Programmable settings on modern multihead weighers allow operators to save and retrieve "recipes" for various items. Because it facilitates rapid setup and minimizes downtime, this functionality is especially helpful in settings where product types change regularly. The weigher's pliability is further increased by the recipe storage feature, which facilitates seamless product changes.

6. Conclusion

The 14 head multihead weigher is an exceedingly valuable tool for accurate and efficient product weighing in industrial settings. Food, pharmaceuticals, while participating bulk retail are just a few of the industries that may profit from its lightning-fast operations and unparalleled precision. Because of its ability to handle a wide range of items with little waste and interoperability with automated packaging systems, the weigher is a highly effective solution that saves money, increases productivity, and meets the demanding requirements of modern commercial packaging environments. If you are looking for multihead weigher manufacturers, please contact Smart Weigh!

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine