Sedert 2012 is Smart Weigh daartoe verbind om kliënte te help om produktiwiteit teen 'n verminderde koste te verhoog.

Vervaardigers en verskaffers van sakverpakkingsmasjiene | Slim weeg

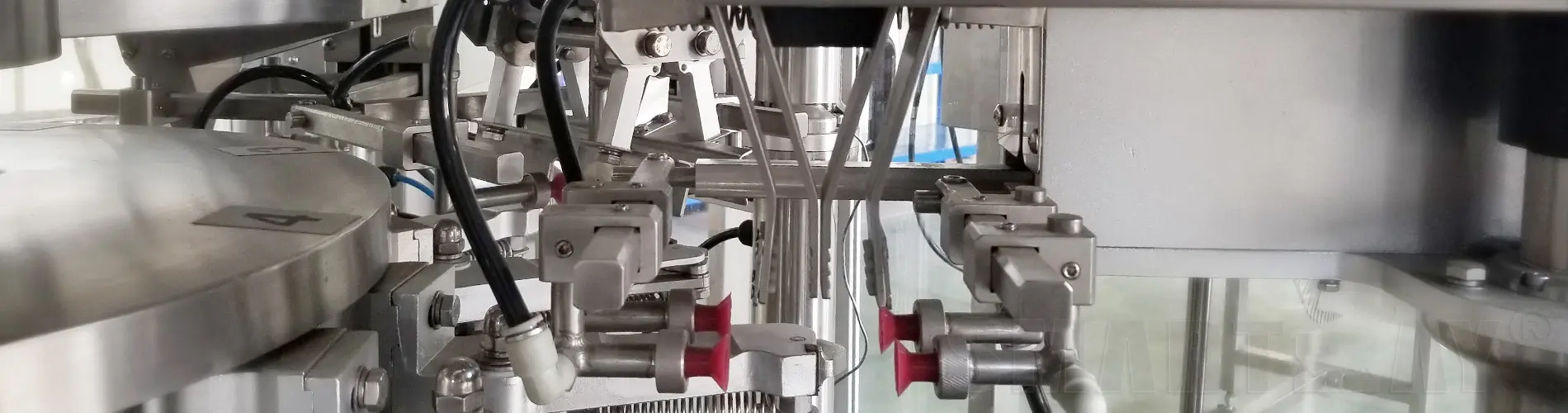

As 'n vooraanstaande vervaardiger van sakverpakkingsmasjiene Vanuit China, met 12 jaar se bedryfservaring, spesialiseer ons by Smart Weigh in die ontwerp en vervaardiging van 'n uitgebreide reeks sakverpakkingsmasjiene. Ons portefeulje sluit gevorderde modelle in soos die roterende sakverpakkingsmasjien, horisontale sakverpakkingsmasjien, vakuumsakverpakkingsmasjien en die kompakte mini-sakverpakkingsmasjien, onder andere. Elke masjien word met presisie en sorg vervaardig om te verseker dat hulle aan die uiteenlopende behoeftes van ons kliënte voldoen.

Ons moderne Voorafgemaakte sakverpakkingsmasjiene is ontwerp om 'n magdom materiale en voorafgemaakte sakformate te hanteer. Dit sluit in die veelsydige staande sakkies, die klassieke plat sakkies, gebruikersvriendelike ritssluiter-doypacks, die esteties aangename 8-sy-seëlsakkies en die robuuste platbodemsakkies. Hierdie wye reeks versoenbaarheid stel besighede in staat om 'n verskeidenheid produkte te verpak en maklik aan te pas by markneigings en verbruikersvoorkeure. Die vermoë om verpakkingstyle te verander sonder die behoefte aan veelvuldige masjiene is nie net 'n gerief nie; dit is 'n strategiese voordeel in vandag se vinnig ontwikkelende mark.

By Smart Weigh verstaan ons dat verpakkingsbehoeftes verder strek as net die masjien. Daarom bied ons omvattende, kant-en-klare verpakkingsoplossings . Hierdie oplossings is aangepas vir 'n wye reeks produkte, insluitend versnaperinge, lekkers, graankosse, koffie, neute, droëvrugte, vleis, bevrore kos en gereed-om-te-eet kos. Ons kant-en-klare oplossings is ontwerp om u verpakkingsproses te stroomlyn, van produkhantering en -weeg tot die finale stadiums van verpakking en verseëling. Hierdie geïntegreerde benadering verseker doeltreffendheid, konsekwentheid en kwaliteit in u verpakkingslyn.

Verder eindig ons toewyding aan innovasie en kwaliteit nie by ons produkte nie. Ons bied uitsonderlike kliëntediens en ondersteuning, wat verseker dat ons kliënte nie net die beste masjiene ontvang nie, maar ook die beste ervaring. As 'n professionele vervaardiger van sakverpakkingsmasjiene , is ons span kundiges altyd gereed om leiding te gee, van die keuse van die regte masjien en konfigurasie vir u spesifieke behoeftes tot die aanbied van deurlopende ondersteuning en onderhoudsdienste.

Hulle werk deur 'n karrousel te roteer waar verskeie sakkies gelyktydig gevul en verseël kan word. Hierdie tipe masjien is ideaal vir 'n verskeidenheid produkte, insluitend vloeistowwe, poeiers en korrels. Die hoëspoedwerking maak dit geskik vir grootskaalse produksieomgewings waar tyd en doeltreffendheid van kritieke belang is.

Die algemene model is 'n 8-stasie roterende sakverpakkingsmasjien . Daarbenewens bied ons unieke modelle vir beide mini- en groter sakgroottes.

Model | SW-R8-200R | SW-R8-300R |

Vulvolume | 10-2000 g | 10-3000 g |

Saklengte | 100-300 mm | 100-350 mm |

Sakkie Breedte | 80-210 mm | 200-300 mm |

Spoed | 30-50 pakke/min | 30-40 pakke/min |

Sakkie Styl | Voorafgemaakte plat sakkie, doypack, ritssluitersakkie, sy-kuilsakkies, tuitsakkies, retortsakkie, 8 sy-seëlsakkies | |

Hulle tel voorafgemaakte sakkies op, maak oop, vul en verseël dit in 'n horisontale vloei. Die horisontale sakverpakkingsmasjiene word gewilde produkte as gevolg van hul kleiner voetspoor en soortgelyke spoedprestasie in vergelyking met roterende verpakkingsmasjiene.

Daar is 2 maniere om sakkies in te voer: vertikale berging en horisontale berging vir die optel van sakkies. Die vertikale tipe het 'n spasiebesparende ontwerp, maar daar is 'n beperking op die hoeveelheid sakkies; die horisontale tipe kan eerder meer sakkies bevat, maar dit benodig meer spasie vir die ontwerp.

Model | SW-H210 | SW-H280 |

Vulvolume | 10-1500 g | 10-2000 g |

Saklengte | 150-350 mm | 150-400 mm |

Sakkie Breedte | 100-210 mm | 100-280 mm |

Spoed | 30-50 pakke/min | 30-40 pakke/min |

Sakkie Styl | Voorafgemaakte plat sakkie, doypack, ritssluitersakkie | |

Mini-sakverpakkingsmasjiene is die perfekte oplossing vir kleinskaalse bedrywighede of besighede wat buigsaamheid met beperkte spasie benodig. Ten spyte van hul kompakte grootte, bied hierdie masjiene 'n reeks funksies in minder stasies, insluitend sakopmaak, vul, verseëling en soms drukwerk. Hulle is ideaal vir opstartondernemings of klein besighede wat doeltreffende verpakkingsoplossings benodig sonder die groot voetspoor van industriële masjiene.

Model | SW-1-430 | SW-4-300 |

Werkstasie | 1 | 4 |

Saklengte | 100-430 mm | 120-300 mm |

Sakkie Breedte | 80-300 mm | 100-240 mm |

Spoed | 5-15 pakke/min | 8-20 pakke/min |

Sakkie Styl | Voorafgemaakte plat sakkie, doypack, ritssluitersakkie, sy-kuilsakkie, M-sakkie | |

Vakuumsakverpakkingsmasjiene is ontwerp om die rakleeftyd van produkte te verleng deur lug uit die sak te verwyder voor verseëling. Hierdie tipe masjien is noodsaaklik vir die verpakking van voedselprodukte soos vleis, kaas en ander bederfbare produkte. Deur 'n vakuum binne die sak te skep, help hierdie masjiene om die varsheid en kwaliteit van die produk te behou, wat hulle 'n gewilde keuse in die voedselbedryf maak.

Model | SW-ZK14-100 | SW-ZK10-200 |

Vulvolume | 5-50 g | 10-1000 g |

Saklengte | ≤ 190 mm | ≤ 320 mm |

Sakkie Breedte | 55-100 mm | 90-200 mm |

Spoed | ≤ 100 sakke/min | ≤ 50 sakke/min |

Sakkie Styl | Voorafgemaakte plat sakkie | |

Voorafgemaakte sakvulmasjiene sluit in lineêre weegers, meerkopwegers, volumetriese koppievullers, skroefvullers en vloeistofvullers.

Produk Tipe | Produkte Naam | Sakkie Verpakkingsmasjien Tipe |

Granulêre produkte | Versnaperinge, lekkergoed, neute, droëvrugte, graankosse, bone, rys, suiker | Meerkopweger/lineêre weegsakverpakkingsmasjien |

Bevrore kos | Bevrore seekos, gehaktballetjies, kaas, bevrore vrugte, kluitjies, ryskoek | |

Gereed om kos te eet | Noedels, vleis, gebraaide rys, | |

Farmaseutiese | Pille, kitsmedisyne | |

Poeierprodukte | Melkpoeier, koffiepoeier, meel | Auger vul sak verpakking masjien |

Vloeibare produkte | Sous | Vloeibare vulstof sak verpakkingsmasjien |

Plak | Tamatiepasta |

Gebou B, Kunxin Industriële Park, No. 55, Dong Fu-pad, Dongfeng-stad, Zhongshan-stad, Guangdong-provinsie, China, 528425

Vinnige skakel

E-pos:export@smartweighpack.com

Tel: +86 760 87961168

Faks: +86-760 8766 3556

Adres: Gebou B, Kunxin Industriële Park, No. 55, Dong Fu-pad, Dongfeng-stad, Zhongshan-stad, Guangdong-provinsie, China, 528425