Automated Meat Weighing Packaging Solutions for Meat Factories and Processors

Running a successful meat processing business requires precision, efficiency, and consistency. Meat processors and factories face the constant challenge of balancing high production volumes with quality control. While customer demands for fresh, safe, and accurately portioned meat products continue to grow, the pressure to meet these standards efficiently has never been higher. That's where Smart Weigh comes in.

At Smart Weigh, we understand the unique needs of the meat industry. From precise meat portioning systems to fully automated meat packing machines, our solutions are designed to help meat processors, factories, and manufacturers streamline their operations and meet the growing demands of the market. Whether you are looking to improve your packaging lines, reduce labor costs, or increase the precision of your portioning, we offer the technology and expertise to elevate your business to the next level.

How Smart Weigh's Solutions Can Help Your Business Thrive

At Smart Weigh, we don't just offer equipment - we provide comprehensive solutions that address the specific challenges faced by meat processors, factories, and manufacturers. Let's take a closer look at how our products can benefit your business.

1. Meat Portioning System

Our Meat Portioning System is designed to provide high-precision portioning for various meat products. Whether you are portioning steaks, roasts, or chicken parts, our system ensures that each piece is cut to the exact size required. This system is crucial for businesses that need to package meat quickly and accurately while maintaining consistent portion sizes.

Benefits:

● Reduces waste by ensuring the exact weight and size of each portion.

● Increases efficiency by automating the portioning process.

● Ensures compliance with industry regulations regarding portion sizes.

● Customizable settings to meet your specific portioning needs.

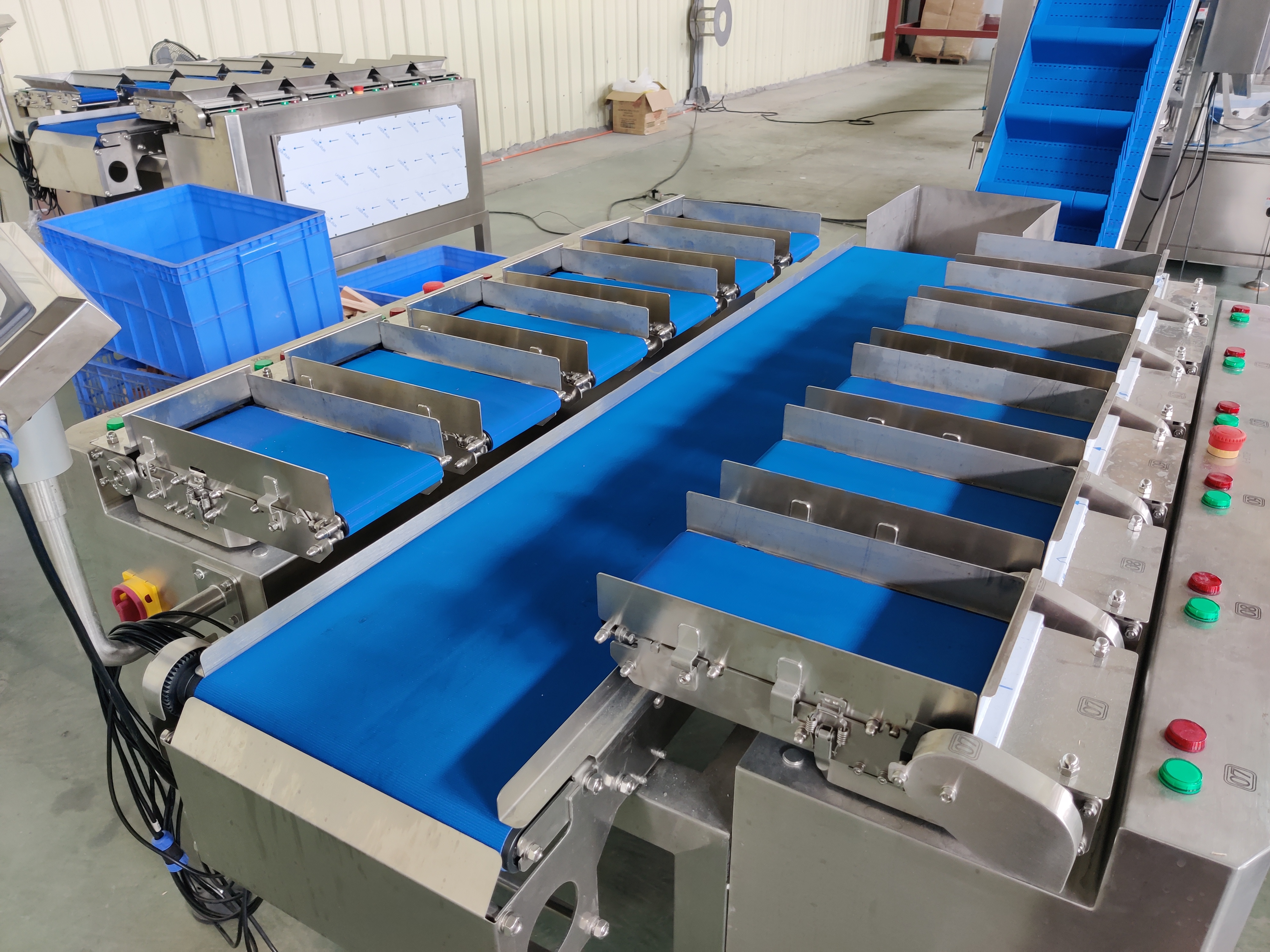

2. Combination Weighers for Meat

When it comes to weighing meat, precision is key. Smart Weigh’s combination weighers for meat offer a versatile and accurate solution for your weighing needs. These machines combine multiple weigh heads to achieve high-speed, high-precision weighing, even when dealing with irregularly shaped products like meat cuts and chunks.

Benefits:

● Ensures precise weighing for different types of meat products.

● Capable of weighing a wide variety of meat sizes and shapes, making it ideal for diverse production lines.

● Reduces product overfill or underfill, helping you maintain consistency across your product range.

● High-speed operation ensures that your production line stays moving at a steady pace.

3. Automatic Meat Packaging Line Solutions

For large-scale meat processors, the need for an automated packaging line is critical. Our automatic meat packaging line solutions integrate all aspects of packaging, from weighing to sealing, into one seamless process. These fully automated systems are designed to increase efficiency, reduce labor costs, and improve overall production capacity.

Benefits:

● Increases speed and efficiency in packaging meat products.

● Reduces the need for manual intervention, lowering labor costs and reducing human error.

● Ensures consistent and high-quality packaging every time.

● Capable of handling various types of packaging, from vacuum-sealed to tray-sealed products.

The Challenges Faced by Meat Processors, Factories, and Manufacturers

Meat processing is a complex operation, with many moving parts that must work seamlessly together. However, there are a few recurring pain points that many in the industry share. Let's explore these challenges and how Smart Weigh’s innovative solutions can help solve them.

1. Precision and Consistency in Portioning and Weighing

One of the primary concerns for any meat processor is the ability to ensure consistent portioning and weighing. Whether it’s steaks, sausages, or ground meat, ensuring that every package contains the correct amount of product is crucial for customer satisfaction and regulatory compliance.

Challenges:

● Inconsistent portion sizes can lead to waste, customer complaints, and lost revenue.

● Traditional weighing methods are often slow and prone to human error, resulting in inaccuracies.

Our Solution:

Smart Weigh's Meat Portioning System is designed to solve this problem by offering highly accurate portioning. This system works by automatically weighing each portion of meat with extreme precision. Whether it's a large cut or a small portion, the system ensures that the meat is portioned according to the exact specifications you need, every single time. This not only improves product consistency but also helps reduce overfills and underfills, saving you money and reducing waste.

2. The Challenge of Labor Shortages and High Operational Costs

Like many industries, meat processing faces a significant labor shortage. With fewer workers available to perform manual tasks, such as weighing, packaging, and sealing, processors are finding it increasingly difficult to meet production demands without sacrificing quality or safety.

Challenges:

● High reliance on manual labor makes meat processing operations less efficient and more prone to errors.

● Labor shortages contribute to higher costs, slower production times, and lower overall efficiency.

Our Solution:

Smart Weigh offers an array of meat packing machines and automated weighing systems that reduce the need for manual labor. Our combination weighers for meat are designed to handle large quantities of meat with minimal intervention, allowing your employees to focus on higher-level tasks while the machine handles the repetitive work. With automated systems in place, production is faster, and costs are lower.

Not only do our machines speed up production, but they also help reduce human error. With automation taking care of the tedious tasks, you’ll see a marked improvement in operational efficiency and a reduction in errors caused by tired or distracted employees.

3. Maintaining Hygiene Standards in High-Speed Operations

Food safety is a top priority for any meat processing facility. Ensuring that every part of the operation, from weighing to packaging, is clean and safe is essential for meeting both regulatory standards and customer expectations. However, balancing hygiene and high-speed production can be a difficult task.

Challenges:

● The need for continuous high-speed operations makes it harder to maintain hygiene and cleanliness.

● Manual cleaning methods can be time-consuming and might not fully meet hygiene requirements.

Our Solution:

Our automatic meat packaging line solutions are designed with hygiene in mind. The machines are built using stainless steel, a material that is easy to clean and resistant to contamination. Additionally, Smart Weigh's systems incorporate automated hygiene control mechanisms, making the cleaning process more efficient and less time-consuming. This ensures that every part of the machine stays clean, reducing the risk of contamination and helping you meet the highest food safety standards.

Why Choose Smart Weigh?

At Smart Weigh, we don't just provide machines—we offer solutions tailored to the unique needs of your business. Here’s why so many meat processors trust us:

1. Cutting-Edge Technology

We pride ourselves on staying at the forefront of packaging and weighing technology. Our products are built with the latest innovations, ensuring that you get the highest quality machines that can handle the demands of modern meat processing.

2. Custom Solutions for Every Need

Every meat processing business is unique, and we understand that. Whether you’re a small meat processor or a large factory, our solutions can be customized to fit your specific needs. From portion control to packaging, we work with you to develop a solution that will help your business run more smoothly and efficiently.

3. Proven Reliability

With years of experience in the industry, Smart Weigh has developed a proven track record of success. We’ve helped hundreds of meat processors around the world increase their efficiency, reduce costs, and improve product quality. Our machines are built to last, and we’re here to support you every step of the way.

Conclusion

The meat processing industry is evolving, and staying ahead means embracing automation and efficiency. With Smart Weigh’s state-of-the-art meat portioning systems, meat packing machines, combination weighers for meat, and automatic meat packaging line solutions, you can streamline your operations, improve product consistency, and reduce costs - giving your business the competitive edge it needs to thrive in a fast-paced market.

If you're ready to take your meat processing operations to the next level, contact Smart Weigh today to learn more about our solutions. Together, we can build a more efficient, profitable, and sustainable future for your business.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine