best bulk multi head weigher multihead factory price for foof handling

1. In the development of Smart Weigh bulk multi head weigher , safety and practicability are both considered. Its precision and quality of manufacture, as well as the management of machine risk and reliability, are all carefully thought of by technicians.

2. The product has been certified officially as per the industry quality standards

3. This product is widely used in many industries. It has the advantage of ensuring high labor productivity, and promotes manufacturers to improve efficiency.

4. The product greatly helps improve the working environment. By using this product, employees can enjoy safer and more comfortable working conditions.

Model | SW-M10 |

Weighing Range | 10-1000 grams |

Max. Speed | 65 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5L |

Control Penal | 7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 10A; 1000W |

Driving System | Stepper Motor |

Packing Dimension | 1620L*1100W*1100H mm |

Gross Weight | 450 kg |

※ Features

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Modular control system, more stability and lower maintenance fees;

◇ Production records can be checked at anytime or download to PC;

◆ Load cell or photo sensor checking to satisfy different requirements;

◇ Preset stagger dump function to stop blockage;

◆ Design linear feeder pan deeply to stop small granule products leaking out;

◇ Refer to product features, select automatic or manual adjust feeding amplitude;

◆ Food contact parts disassembling without tools, which is easier to clean;

◇ Multi-languages touch screen for various clients, English, French, Spanish, etc;

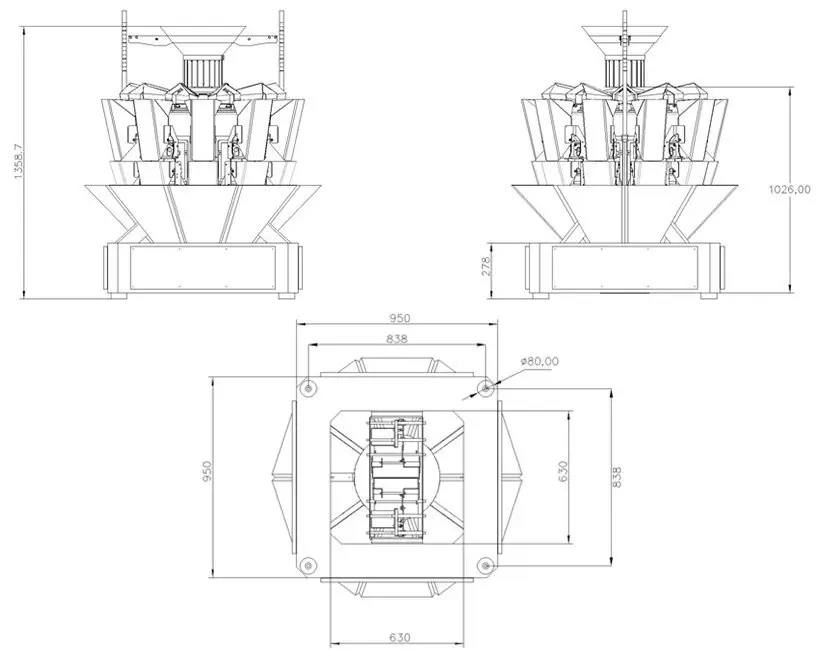

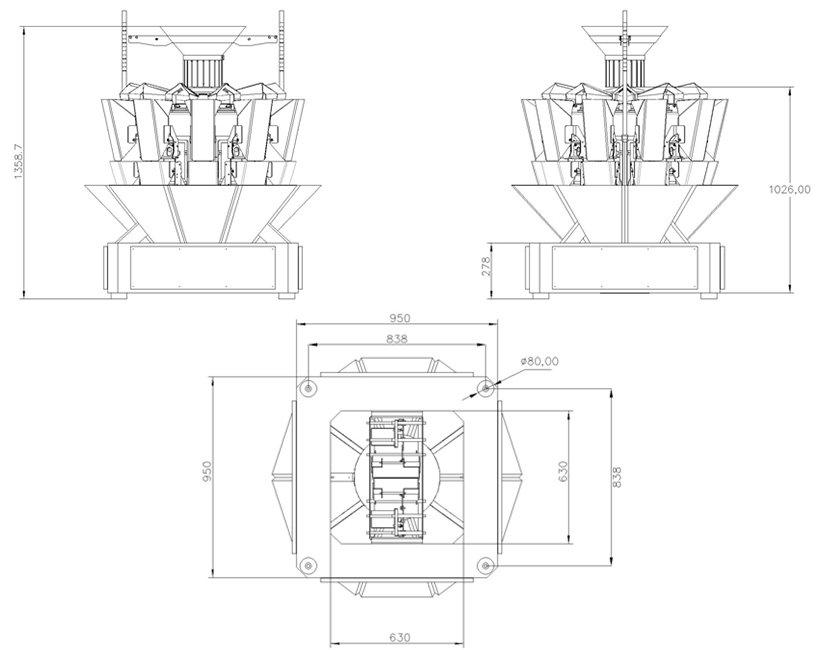

※ Dimensions

※ Application

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

※ Function

※ Product Certificate

Company Features

1. Smart Weigh Packaging Machinery Co., Ltd focuses on providing customers with the best system solutions and international advanced bulk multi head weigher products.

2. Our company has world-class manufacturing facilities. By introducing cutting-edge production engineering and quality control technologies to instrument production, we ensure a quality level held in high esteem throughout the world.

3. With the great dream of being a good manufacturer of bagging machine , Smart Weigh will work harder to increase customer satisfaction. Inquire now! You are able to get our multihead weigher manufacturers and receive decent support . Inquire now!

Quick Link

Packing Machine