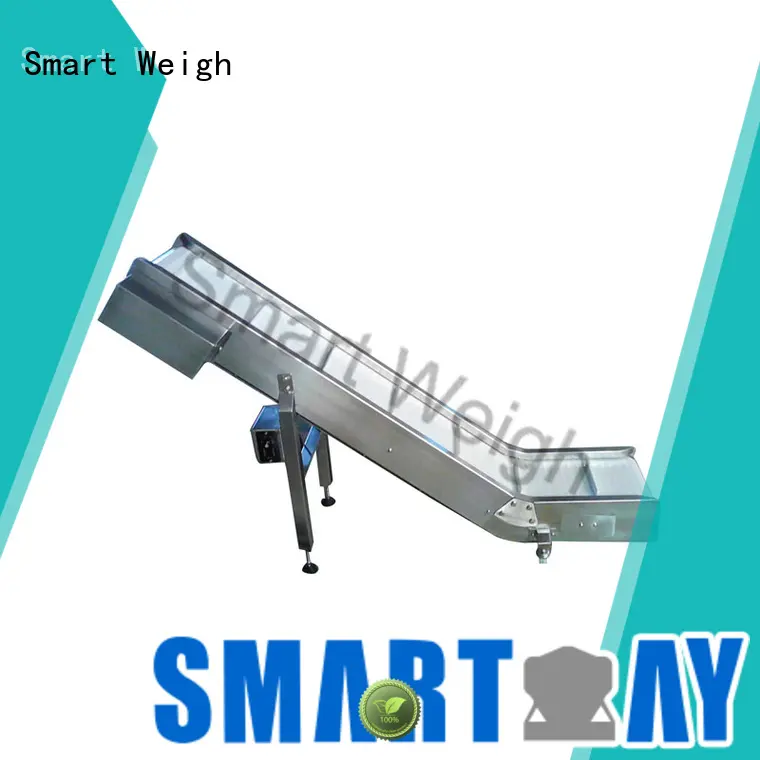

durable bucket conveyor output in bulk for food labeling

With several productions bases, Smart Weigh Packaging Machinery Co., Ltd supplies bucket conveyor in large quantity.

brand

smart weigh

country of origin

china

material

sus304 construction

loading port

zhongshan port, china

production

15 sets/month

moq

1 sets

payment

tt, lc

Company Advantages

1. bucket conveyor is made by aluminum work platform which provides a number of advantages.

2. Our technical team has been dedicated themselves into developing aluminum work platform for bucket conveyor .

3. Owing to its stable ability, bucket conveyor have been highly favored by the majority of our customers.

4. Smart Weigh Packaging Machinery Co., Ltd keeps carrying out innovations in the technology of bucket conveyor .

5. Smart Weigh has constructed a relatively complete bucket conveyor process line to ensure the quality.

Company Features

1. With several productions bases, Smart Weigh Packaging Machinery Co., Ltd supplies bucket conveyor in large quantity.

2. Smart Weigh has a dominant place in output conveyor industry thanks to its aluminum work platform .

3. We strive to cultivate a healthy, diverse and inclusive culture where all our employees can fulfill his or her potential, and thereby ensuring the ongoing viability, growth, and success of our company. Our aim is to surpass our customers’ expectations every time. We know all about the demands placed on the products’ end uses and we promote our customers’ businesses through innovative product and service solutions.

1. bucket conveyor is made by aluminum work platform which provides a number of advantages.

2. Our technical team has been dedicated themselves into developing aluminum work platform for bucket conveyor .

3. Owing to its stable ability, bucket conveyor have been highly favored by the majority of our customers.

4. Smart Weigh Packaging Machinery Co., Ltd keeps carrying out innovations in the technology of bucket conveyor .

5. Smart Weigh has constructed a relatively complete bucket conveyor process line to ensure the quality.

※ Application:

b

The machine output packed products to check machines, collecting table or flat conveyor.

※ Specification:

bg

Convey Height: 1.2~1.5m;

Belt Width: 400 mm

Convey volumes: 1.5m3/h.

Company Features

1. With several productions bases, Smart Weigh Packaging Machinery Co., Ltd supplies bucket conveyor in large quantity.

2. Smart Weigh has a dominant place in output conveyor industry thanks to its aluminum work platform .

3. We strive to cultivate a healthy, diverse and inclusive culture where all our employees can fulfill his or her potential, and thereby ensuring the ongoing viability, growth, and success of our company. Our aim is to surpass our customers’ expectations every time. We know all about the demands placed on the products’ end uses and we promote our customers’ businesses through innovative product and service solutions.

Product Comparison

This good and practical weighing and packaging Machine is carefully designed and simply structured. It is easy to operate, install, and maintain.Smart Weigh Packaging's weighing and packaging Machine has better performances in the following aspects.

Application Scope

multihead weigher is widely used in industrial production, such as fields in food and beverage, pharmaceutical, daily necessities, hotel supplies, metal materials, agriculture, chemicals, electronics, and machinery.According to different needs of customers, Smart Weigh Packaging is capable of providing reasonable, comprehensive and optimal solutions for customers.

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Contact Us

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Contact us

Leave your inquiry, we will provide you with quality products and services!

Contact us

whatsapp

Contact customer service

Contact us

whatsapp

cancel

Customer service