ʻEhia mau ʻano o ka mīkini hoʻopili meaʻai holoholona?

I nā makahiki he ʻumi i hala iho nei, ua ulu nui ka ʻoihana meaʻai holoholona. I ka nui o ka poʻe e lilo i mea nona nā holoholona, ua piʻi pū ko lākou mau manaʻolana no ka ʻōpala meaʻai holoholona kiʻekiʻe a maʻalahi hoʻi. ʻO kēia piʻi ʻana o ke koi ʻana, ʻoi aku ka nui o nā hopena ʻōpala kūpono a maikaʻi hoʻi ma mua o ka wā ma mua. ʻO ka ʻōpala kūpono ke kī i ka mālama ʻana i ka pono o ka huahana, ka hōʻoia ʻana i ka palekana, a me ka hoʻonui ʻana i ka hoihoi o ka papa. E luʻu kākou i loko o nā ʻano mīkini ʻōpala meaʻai holoholona like ʻole, ko lākou mau hiʻohiʻona, a pehea lākou e pōmaikaʻi ai i nā ʻoihana ma ka ʻoihana meaʻai holoholona. Ua hoʻolālā ʻia kēia mau mīkini no ka ʻeke ʻana, ka ʻōwili ʻana, a i ʻole ka hoʻopiha ʻana i ka ipu i ka meaʻai holoholona a me nā meaʻai holoholona.

Nā ʻAno Mīkini Hoʻopili Meaʻai Holoholona

1. Nā Mīkini Hoʻopiha Palapala Kū pololei (VFFS)

Wehewehe: He nui nā ʻano hana like ʻole a me ka pono o nā mīkini VFFS. Hoʻokumu lākou, hoʻopiha, a sila i nā ʻeke ma ke ʻano kū pololei, e kūpono ai no ka meaʻai holoholona maloʻo a me nā meaʻai liʻiliʻi. Hoʻomaka ke kaʻina hana me kahi ʻōwili o ke kiʻiʻoniʻoni i hana ʻia i loko o kahi paipu. Hoʻopaʻa ʻia ka lalo, hoʻopiha ʻia ka huahana i loko o ka paipu, a laila hoʻopaʻa ʻia ka luna e hana i kahi ʻeke piha.

Kūpono No : Meaʻai holoholona maloʻo, nā meaʻai liʻiliʻi.

Nā Hiʻohiʻona Koʻikoʻi :

Hana wikiwiki

Ka nui a me ke ʻano o ka ʻeke kūlike

Ka hoʻohana pono ʻana i nā mea hoʻopili

2. Nā Mīkini ʻUhi Kahe Paepae

Hoʻopili kēia mau mīkini i nā huahana i loko o ke kahe mau o ka ʻiliʻili, e sila ana i nā wēlau ʻelua. He kūpono lākou no nā meaʻai i wahī ʻia pākahi a me nā ʻeke liʻiliʻi. Hoʻokomo ʻia ka huahana ma luna o ka ʻiliʻili, wahī ʻia, a sila ʻia.

Kūpono No : Nā meaʻai i wahī pākahi ʻia, nā ʻeke liʻiliʻi.

Nā Hiʻohiʻona Koʻikoʻi :

Ka hoʻopili wikiwiki

Ka laulā o nā nui a me nā ʻano o nā huahana

Ka palekana huahana maikaʻi loa

3. Nā Mīkini Hoʻopili ʻEke i Hana mua ʻia

Hoʻopiha a sila kēia mau mīkini i nā ʻeke i hana mua ʻia a me nā ʻeke kū. He mea kaulana loa ka ʻōpala ʻeke kū i ka ʻoihana meaʻai holoholona, ʻoi aku hoʻi no nā ʻeke ʻano doy a me quad me nā pani zipper. He maikaʻi loa lākou no ka meaʻai holoholona pulu a me nā meaʻai kiʻekiʻe. Hoʻokomo ʻia nā ʻeke i hana mua ʻia i loko o ka mīkini, hoʻopiha ʻia me ka huahana, a laila sila ʻia.

Kūpono No : Nā meaʻai holoholona pulu, nā meaʻai holoholona kiʻekiʻe.

Nā Hiʻohiʻona Koʻikoʻi :

Kiʻekiʻe ke kikoʻī i ka hoʻopiha ʻana

Nā hoʻolālā ʻeke nani

Hoʻohui maʻalahi me nā ʻōnaehana hoʻopili ʻē aʻe

4. Nā Mīkini ʻEke ʻAkomi

Hoʻolālā ʻia no ka hoʻopili ʻana i nā meaʻai holoholona nui, ʻoi aku ka nui o kēia mau mīkini, hiki ke hoʻopiha i nā ʻeke nui, sila iā lākou, a hoʻomākaukau iā lākou no ka hāʻawi ʻana. He kūpono lākou no nā laina hana nui. He kūpono kēia mau mīkini ʻeke ʻakomi no ka hoʻopiha a me ka sila ʻana i nā ʻeke kū i luna, e hāʻawi ana i ka maʻalahi o ka hoʻohana, ka hoʻomaʻemaʻe, a me ka lawelawe ʻana.

Kūpono No : ʻAi holoholona maloʻo nui.

Nā Hiʻohiʻona Koʻikoʻi :

Ka pono kiʻekiʻe

Ke kaupaona pololei a me ka hoʻopiha ʻana

Kūkulu paʻa no ka lawelawe ʻana i nā nui nui

5. Nā Mīkini Hoʻopiha a Sila i nā Kini

Hana kūikawā ʻia no ka hoʻopili ʻana i ka meaʻai holoholona pulu i loko o nā kini, hoʻopiha a sila kēia mau mīkini i nā kini e hōʻoia i ka hou a pale i ka haumia.

Kūpono No : Meaʻai holoholona pulu i loko o ka kini.

Nā Hiʻohiʻona Koʻikoʻi :

Sila paʻa ea

Kūpono no nā huahana wai kiʻekiʻe

Hana paʻa a hilinaʻi hoʻi

6. Nā Mīkini Pahu

Hoʻohana ʻia kēia mau mīkini no ka hoʻopili ʻana i nā ʻāpana he nui o nā huahana meaʻai holoholona i loko o nā pahu pepa, kūpono kēia mau mīkini no nā meaʻai he nui a me nā ʻano hoʻopili huahana like ʻole. Hoʻokele lākou i ke kaʻina hana o ka hoʻokumu ʻana, hoʻopiha ʻana, a me ka sila ʻana i nā pahu pepa.

Kūpono No : Nā meaʻai he nui-ʻeke, nā ʻūpā huahana like ʻole.

Nā Hiʻohiʻona Koʻikoʻi :

Ka lawelawe ʻana i nā pahu pepa me ka maikaʻi

Ka maʻalahi o ka nui o ka pahu

Hana wikiwiki

Nā Hiʻohiʻona o nā Mīkini Hoʻopili Meaʻai Holoholona

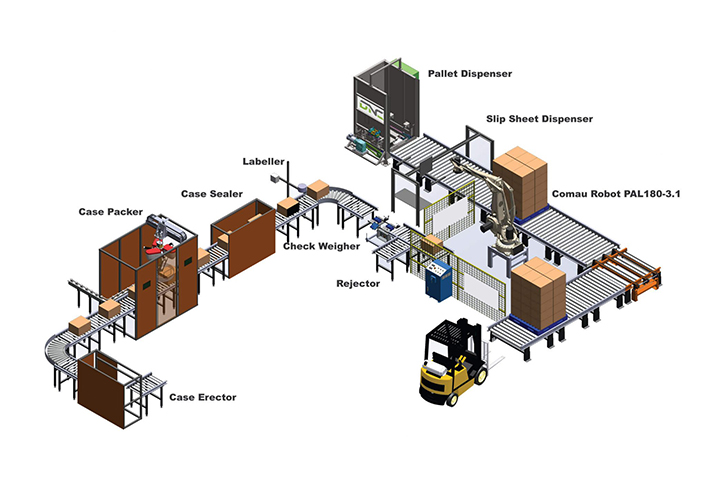

Nā ʻōnaehana hana aunoa a me ko lākou mau pono

Hoʻonui nā lako hana ʻakomi no ka hoʻopili ʻana i nā meaʻai holoholona i ka pono a hoʻemi i nā kumukūʻai hana. Hoʻomaopopo lākou i ka maikaʻi o ka hoʻopili ʻana, hoʻemi i ka hewa kanaka, a hoʻonui i ka wikiwiki o ka hana. Hiki i kēia mau ʻōnaehana ke lawelawe i nā hana hoʻopili like ʻole, mai ka hoʻopiha ʻana a me ke sila ʻana a hiki i ka lepili ʻana a me ka palletizing.

Nā Koho Hoʻopilikino

Hāʻawi nā mīkini hoʻopili hou i nā koho hoʻopilikino e hoʻokō i nā ʻano hoʻopili like ʻole a me nā nui. ʻAʻole hiki ke hoʻonui ʻia ke koʻikoʻi o nā ʻano hoʻopili no nā meaʻai holoholona organik e hōʻoia i kahi ola papa olakino a me ka piʻi ʻana o ka makemake o nā mea kūʻai aku no nā mea hoʻopili aloha kaiapuni. Hiki i nā ʻoihana ke koho i nā mīkini e hoʻokō i kā lākou mau pono kikoʻī, inā no nā ʻeke liʻiliʻi, nā ʻeke nui, a i ʻole nā hoʻolālā hoʻopili kū hoʻokahi.

Ka Pololei i ke Kaupaona a me ka Hoʻopiha ʻana

He mea koʻikoʻi ke kaupaona pololei a me ka hoʻopiha ʻana no ka mālama ʻana i ka maikaʻi o ka huahana a me ka hoʻokō ʻana i nā kūlana hoʻoponopono. Loaʻa nā mīkini hoʻopili holomua me nā ʻano hana kikoʻī e hōʻoia i loaʻa i kēlā me kēia pūʻolo ka nui kūpono o ka huahana.

ʻenehana sila

He mea nui ka ʻenehana sila pono no ka mālama ʻana i ka hou a me ka maikaʻi o ka meaʻai holoholona. Hoʻohana nā mīkini hoʻopili i nā ʻano hana like ʻole, e like me ke sila wela, ke sila ultrasonic, a me ka sila vacuum, e hōʻoia i nā sila airtight e pale ai i ka huahana mai ka haumia a me ka palaho.

Nā Pōmaikaʻi o nā Mīkini Hoʻopili Hana ʻAkomi

Hoʻonui i ka pono o ka hana ʻana

Hoʻomaʻalahi nā mīkini hoʻopili automated i ke kaʻina hana, e ʻae ana i nā ʻoihana e hoʻonui i kā lākou helu hana. Hiki i nā mīkini wikiwiki ke lawelawe i nā nui he nui o ka meaʻai holoholona, e hōʻoiaʻiʻo ana i kahi lako paʻa e hoʻokō ai i nā koi o ka mākeke.

Hoʻemi ʻia nā kumukūʻai hana

Hoʻemi ka hana automation i ka pono no ka hana lima, e hoʻemi ana i nā kumukūʻai hana. Hoʻemi pū ia i ka pilikia o nā ʻeha ma ka wahi hana e pili ana i nā hana hoʻopili hou.

Ka Kūlana Mau o ka ʻŌpala

Hoʻomaopopo nā mīkini hana aunoa i ka maikaʻi o ka hoʻopili ʻana ma o ka hana ʻana i nā hana me ka pololei a me ke kikoʻī. He mea nui kēia kūlike no ka mālama ʻana i ka inoa o ka brand a me ka ʻoluʻolu o ka mea kūʻai aku.

Ka hiki ke hoʻonui ʻia no nā ʻoihana e ulu ana

Hiki ke hoʻonui ʻia nā mīkini hoʻopili e hoʻokō i nā pono e ulu nei o nā ʻoihana. ʻAe nā hoʻolālā modular i nā ʻoihana e hoʻohui i nā hiʻohiʻona hou a me nā hiki ke piʻi aʻe i kā lākou mau koi hana.

Hopena

He mea koʻikoʻi ke koho ʻana i ka mīkini hoʻopili meaʻai holoholona kūpono no ka hōʻoia ʻana i ka maikaʻi o ka huahana, ka pono o ka hana, a me ka ʻoluʻolu o ka mea kūʻai aku. Ma ka hoʻomaopopo ʻana i nā ʻano mīkini hoʻopili like ʻole a me kā lākou mau hiʻohiʻona, hiki i nā ʻoihana ke hana i nā hoʻoholo naʻauao e kōkua iā lākou e hoʻokūkū i ka mākeke meaʻai holoholona e ulu nei. ʻO ka hoʻopukapuka kālā ʻana i nā hoʻonā hoʻopili holomua ʻaʻole wale e hoʻonui i ka hoihoi o ka huahana akā hoʻonui pū i ka huahana holoʻokoʻa a me ka loaʻa kālā.

He alakaʻi honua ʻo Smart Weigh i nā ʻōnaehana kaupaona pololei a me nā ʻōnaehana hoʻopili i hoʻohui ʻia, i hilinaʻi ʻia e 1,000+ mau mea kūʻai aku a me 2,000+ mau laina hoʻopili ma ka honua holoʻokoʻa. Me ke kākoʻo kūloko ma Indonesia, ʻEulopa, USA a me UAE , hāʻawi mākou i nā hoʻonā laina hoʻopili turnkey mai ka hānai ʻana a i ka palletizing.

Loulou wikiwiki

Mīkini Hoʻopaʻa