Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Pouch Packing Machine Manufacturers & Suppliers | Smart Weigh

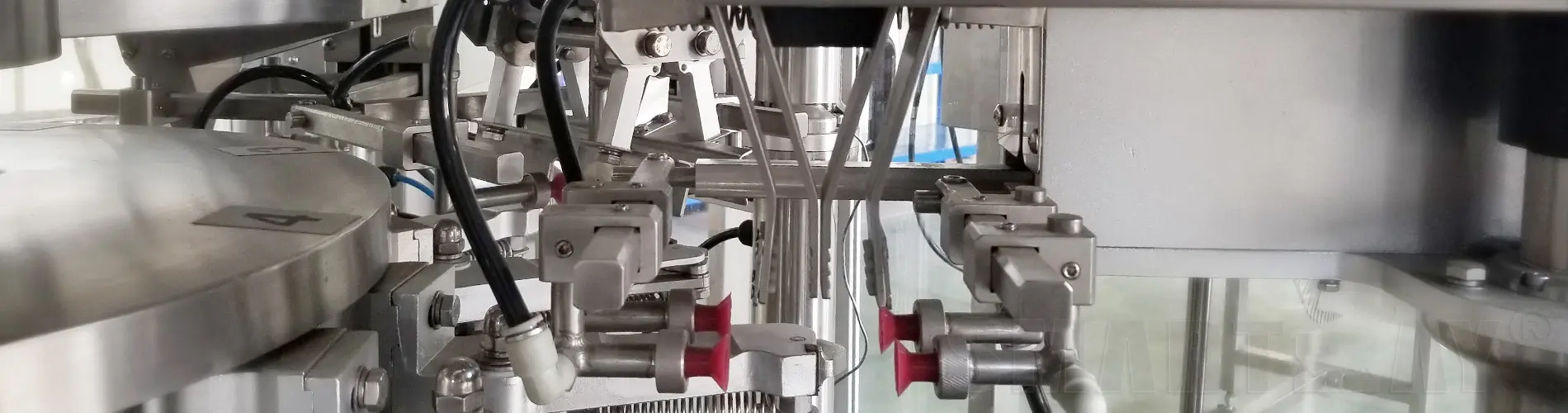

As a premier pouch packaging machine manufacturer from China, boasting 12 years of industry experience, we at Smart Weigh specialize in designing and manufacturing an extensive range of pouch packing machines. Our portfolio includes advanced models such as the rotary pouch packing machine, horizontal pouch packing machine, vacuum pouch packaging machine, and the compact mini pouch packing machine, among others. Each machine is crafted with precision and care, ensuring they meet the diverse needs of our clients.

Our modern pre made pouch packing machines are engineered to handle a myriad of materials and premade pouch formats. This includes the versatile stand-up pouches, the classic flat pouches, user-friendly zipper doypacks, the aesthetically pleasing 8 side seal pouches, and the robust flat bottom pouches. This wide range of compatibility allows businesses to package a variety of products, adapting to market trends and consumer preferences with ease. The ability to switch packaging styles without the need for multiple machines is not just a convenience; it's a strategic advantage in today's fast-paced market.

At Smart Weigh, we understand that packaging needs extend beyond just the machine. That's why we offer comprehensive turnkey packaging solutions. These solutions are tailored to a wide array of products including snacks, candy, cereals, coffee, nuts, dry fruits, meat, frozen food, and ready-to-eat foods. Our turnkey solutions are designed to streamline your packaging process, from product handling and weighing to the final stages of packing and sealing. This integrated approach ensures efficiency, consistency, and quality in your packaging line.

Furthermore, our commitment to innovation and quality doesn't end with our products. We offer exceptional customer service and support, ensuring that our clients not only receive the best machines but also the best experience. As a professional pouch packing machine manufacturer, our team of experts is always ready to provide guidance, from selecting the right machine and configuration for your specific needs to offering ongoing support and maintenance services.

They operate by rotating a carousel where multiple pouches can be filled and sealed simultaneously. This type of machine is ideal for a variety of products, including liquids, powders, and granules. Its high-speed operation makes it suitable for large-scale production environments where time and efficiency are crucial.

The common model is 8 stations rotary pouch packaging machine. In addition, we offer unique models both for mini and larger pouch sizes.

Model | SW-R8-200R | SW-R8-300R |

Filling Volume | 10-2000 g | 10-3000 g |

Pouch Length | 100-300 mm | 100-350 mm |

Pouch Width | 80-210 mm | 200-300 mm |

Speed | 30-50 packs/min | 30-40 packs/min |

Pouch Style | Premade flat pouch, doypack, zippered bag, side gusset pouches, spout pouches, retort pouch, 8 side seal pouches | |

They pick up, open, fill and seal premade pouches in horizontal flow. The horizontal pouch packaging machines become hot product because of their smaller footprint and similar speed performance compared with rotary packing machine.

There are 2 pouch feeding manners: vertical storage and horizontal storage for pouches picking up. Vertical type is with space-saving design, but limit for storage pouches quantity; instead, horizontal type can contain more pouches, but it needs longer space for the design.

Model | SW-H210 | SW-H280 |

Filling Volume | 10-1500 g | 10-2000 g |

Pouch Length | 150-350 mm | 150-400 mm |

Pouch Width | 100-210 mm | 100-280 mm |

Speed | 30-50 packs/min | 30-40 packs/min |

Pouch Style | Premade flat pouch, doypack, zippered bag | |

Mini pouch packing machines are the perfect solution for small-scale operations or businesses that require flexibility with limited space. Despite their compact size, these machines offer a range of functions in less station, including pouch opening, filling, sealing, and sometimes printing. They are ideal for startups or small businesses that need efficient packaging solutions without the large footprint of industrial machines.

Model | SW-1-430 | SW-4-300 |

Working Station | 1 | 4 |

Pouch Length | 100-430 mm | 120-300 mm |

Pouch Width | 80-300 mm | 100-240 mm |

Speed | 5-15 packs/min | 8-20 packs/min |

Pouch Style | Premade flat pouch, doypack, zippered bag, side gusset pouch, M pouch | |

Vacuum pouch packing machines are designed to extend the shelf life of products by removing air from the pouch before sealing. This type of machine is essential for packaging food products like meats, cheeses, and other perishables. By creating a vacuum inside the pouch, these machines help in preserving the freshness and quality of the product, making them a popular choice in the food industry.

Model | SW-ZK14-100 | SW-ZK10-200 |

Filling Volume | 5-50 g | 10-1000 g |

Pouch Length | ≤ 190 mm | ≤ 320 mm |

Pouch Width | 55-100 mm | 90-200 mm |

Speed | ≤ 100 bags/min | ≤ 50 bags/min |

Pouch Style | Premade flat pouch | |

Pre made pouch filling machines include linear weighers, multihead weighers, volumetric cup fillers, auger fillers, and liquid fillers.

Product Type | Products Name | Pouch Packing Machine Type |

Granular products | Snacks, candy, nuts, dry fruits, cereals, beans, rice, sugar | Multihead weigher/linear weigher pouch packing machine |

Frozen food | Frozen seafood, meatballs, cheese, frozen fruits, dumplings, rice cake | |

Ready to eat food | Noodles, meat, fried rice, | |

Pharmaceutical | Pills, instant medicines | |

Powder products | Milk powder, coffee powder, flour | Auger filler pouch packing machine |

Liquid products | Sauce | Liquid filler pouch packing machine |

Paste | Tomato paste |

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425