Mochini o tlatsang lipompong tse thata o balang linkho thepa ea ho paka Mohala oa Tlhahiso

Kopo | Lijo, seno, bongaka, meriana, lijo-thollo joalo-joalo |

Lebitso la mochini | Mochini oa ho tlatsa botlolo / Can |

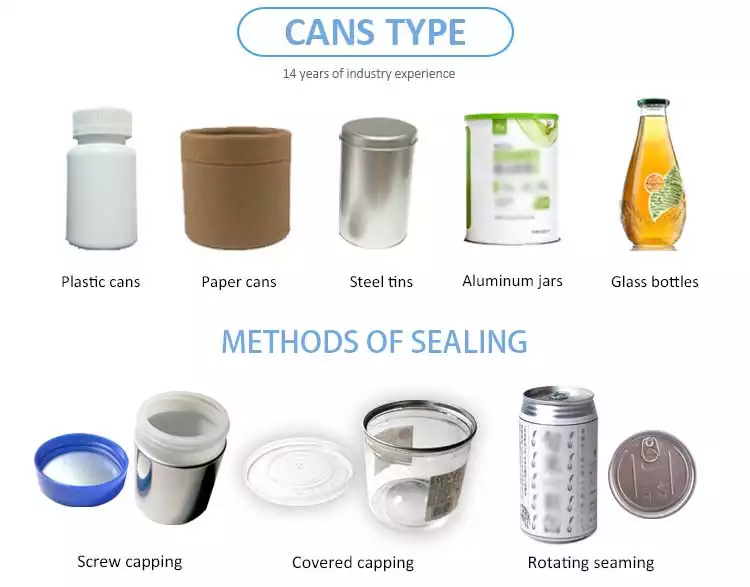

Lintho tsa ho paka | Plastiki, pampiri, tšepe, Tin can |

Tekanyo e ikemetseng | Ka ho feletseng-ka ho iketsa |

Mofuta o khannoang | Motlakase |

Lebelo la ho tlatsa | 30-50bottles/min, ho ipapisitse le boima ba botlolo ka 'ngoe |

Ho tlatsa ho nepahala | ±1% |

Ho tlatsa boima ba 'mele | 50-2000 g |

Mokhoa oa ho lekanya | Electroni weigher/Piston filler/Pompo |

Phepelo ea motlakase | Karolo e meraro ea 380/220V 50-60Hz / 2kw |

Likarolo tsa mantlha | Motor, PLC etc |

Lintho tsa mochini | Tšepe e sa hloekang 304 kapa 316 |

Boima ba 'mele | 720KGS |

Dimension(L*W*H) | 3000x900x1800mm |

1. Ho hlomelloa ka ts'ireletso ea ts'ireletso, latela melao e tiileng's litlhoko tsa tsamaiso ea polokeho.

2. Lisebelisoa tse feto-fetohang bakeng sa lijo-thollo, Granule, kapa Granules ho kopanya lisebelisoa tsa metsi Bottling kapa Canning ka ho fetola lisebelisoa tse fapaneng tsa dosing. Lihlahisoa tsa Granule le Grain li noa ka sekala sa Multi-heads kapa Liner scale. Lihlahisoa tsa Liquids tse nooang ka Piston filler kapa Pump.

3. Sebelisa PLC Servo System le pneumatic control system le super touch screen ho qapa setsi sa taolo ea koloi se eketsang mochini kaofela.'s taolo ho nepahala, ho tšepahala le boemo bo bohlale.

4. Sesepa sa ho ama se ka boloka litekanyo tsa tekheniki tsa mefuta e fapaneng ea lihlahisoa, ha ho hlokahale ho hlophisa bocha ha lihlahisoa li ntse li tsoela pele.

ho fetoha.

5. Ka phoso e bontšang tsamaiso , e thusang ho sebetsana le bothata hang-hang.

6. E fumaneha ho hokahanya le mochine oa Capping, ho hlahloba sekala, mochine oa Labeling le mochine oa cartoning ho fumana libotlolo tse feletseng kapa mohala oa ho paka oa Cans.

7.Likarolo tsohle le likopano tse kopanang le phofo li entsoe ka S.S.304 'me li ka tlosoa habonolo bakeng sa phetoho ea tlhokomelo.

8. HA HO KA, HA HO TLATSA" Sisteme e felisa tšenyo ea phofo e theko e boima, ha feela e ka ba teng ebe ho qala ho tlatsa.

9. Can Feeding e ne e laoloa ke tsamaiso ea servo e hlahang ka ts'ebetso e tsitsitseng le boemo bo nepahetseng.

Sistimi ea 10.Powder Filling e ne e laoloa ke sistimi ea servo e nang le lebelo le feto-fetohang la ho tlatsa le ho nepahala ho phahameng.

Mochini ona oa othomathike oa ho bekha le ho paka o loketse ho paka granule, selae, roll kapa thepa ea sebopeho se sa tloaelehang joalo ka lipompong, peo, jelly, fries, granule ea kofi, peanut, lijo tse puffy, biscuit, chokolete, linate, lijo tsa phoofolo ea lapeng ea yogurt, lijo tse hatselitsoeng. , joalo-joalo.