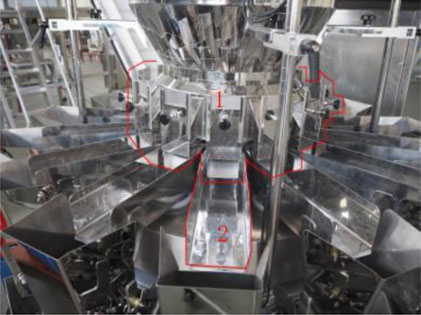

Anti-leak feeding device with deep "U" shape feeding pan

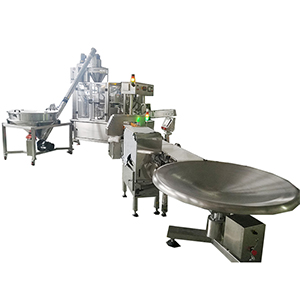

1-5kg Sugar Rice Salt Packing Machine

The sugar packing machine is customized for 1-5kg weight, anti-leaking device helps you save materials cost. It is also used for similar tiny granule, such as salt and rice.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Our sugar packing machine is multihead weigher integrated with vertical form fill seal machine, infeed conveyor and outfeed conveyor. This packing system is mainly applying in small or tiny granule, such as white sugar, salt, rice and etc.

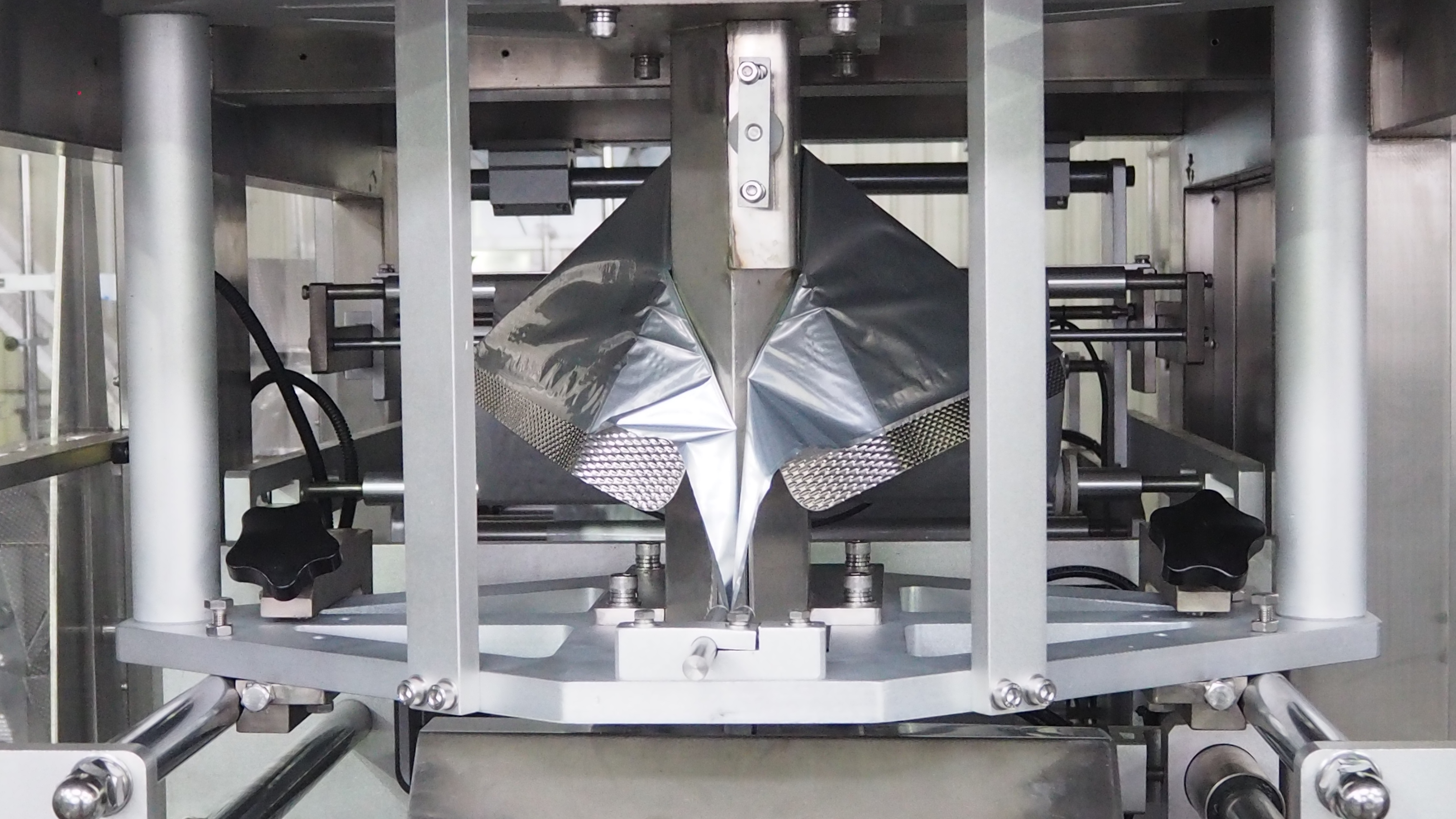

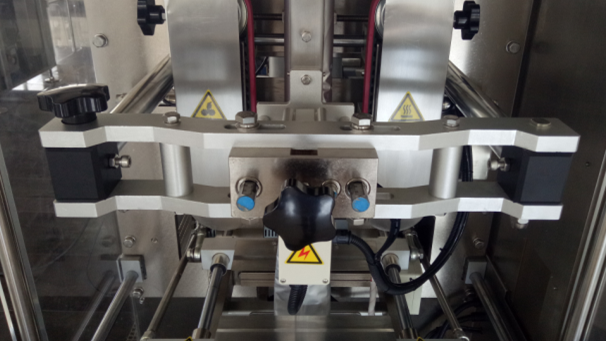

Pillow bag and gusset bag are available. The option device can make the punch hole, euro hole in the sealing position.

| Weighing range | 1-5 KG |

| Speed | 10-50 packs/min (depends on actual weight and bag size) |

| Accuracy | Within 3 grams |

| Bag style | Pillow bag, gusset bag |

| Bag size | Width 80-300mm, length 120-450mm |

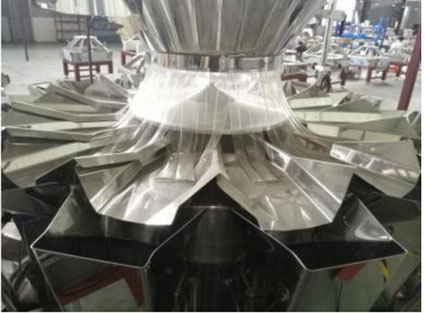

1. The multihead weigher is customized for sugar, rice and salt. There is a set of anti-leaking device, includes customize top cone, U shape feeding pan and anti-leak hoppers.

2. The design of multi head weigher and packing machine is for 1-5kg bags.

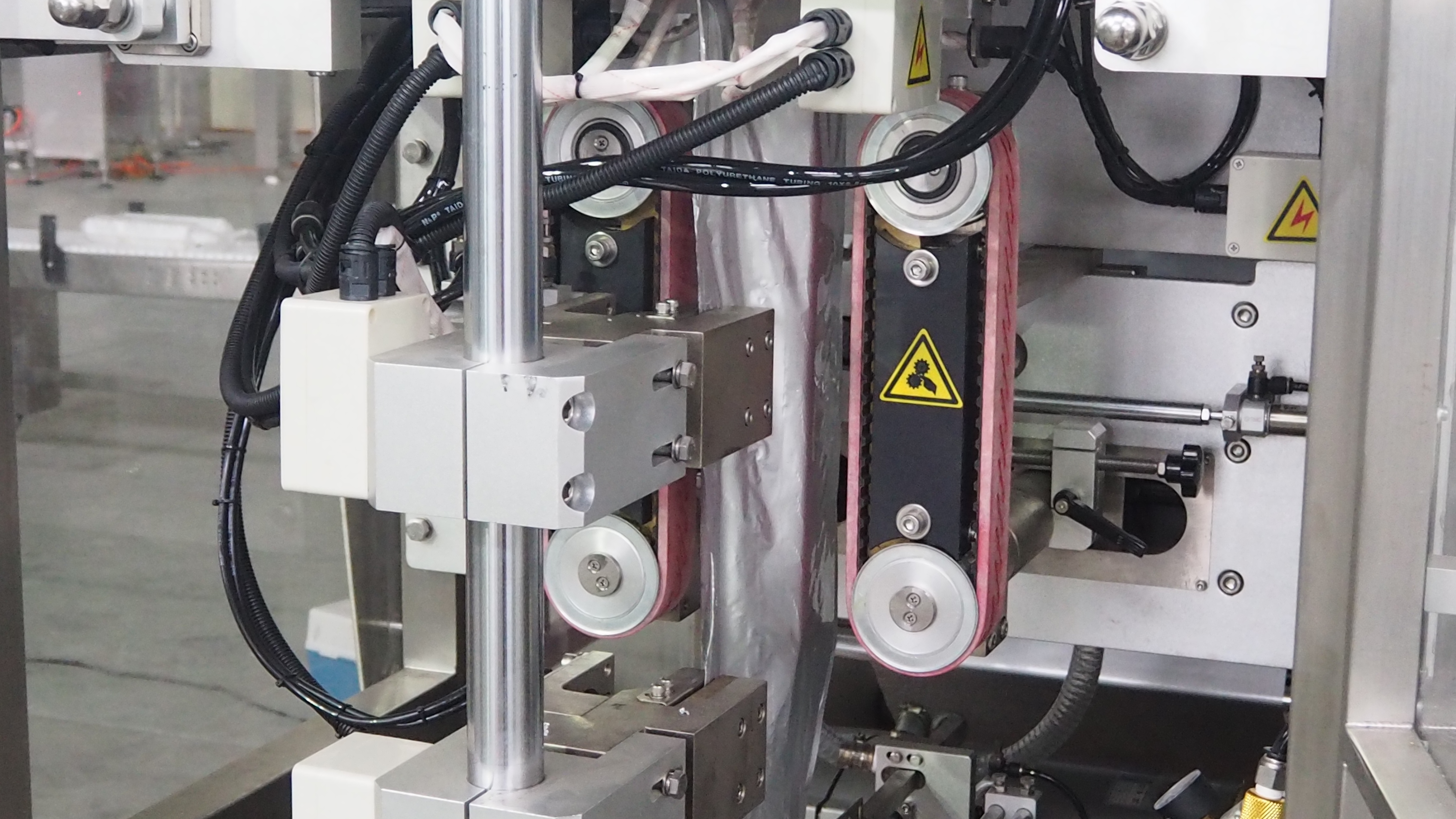

3. Packing machine is with branded PLC, weigher is with modular control system, easy to operate and maintenance.

4. Adjustable bag length, temperature and speed.

1. Prevent material drops out when conveyor feeding to weigher

2. Prevent material heaps up at the front-end

3. Deep U shape feeding pan can storage more materials, which is good for higher speed

1. Fully-automatically procedures from material feeding, weighing, fling, forming, sealing, date-printing to finished products output;

2. High weighing precision and production capacity;

3. Open door alarm and stop machine running in any condition for safety regulation;

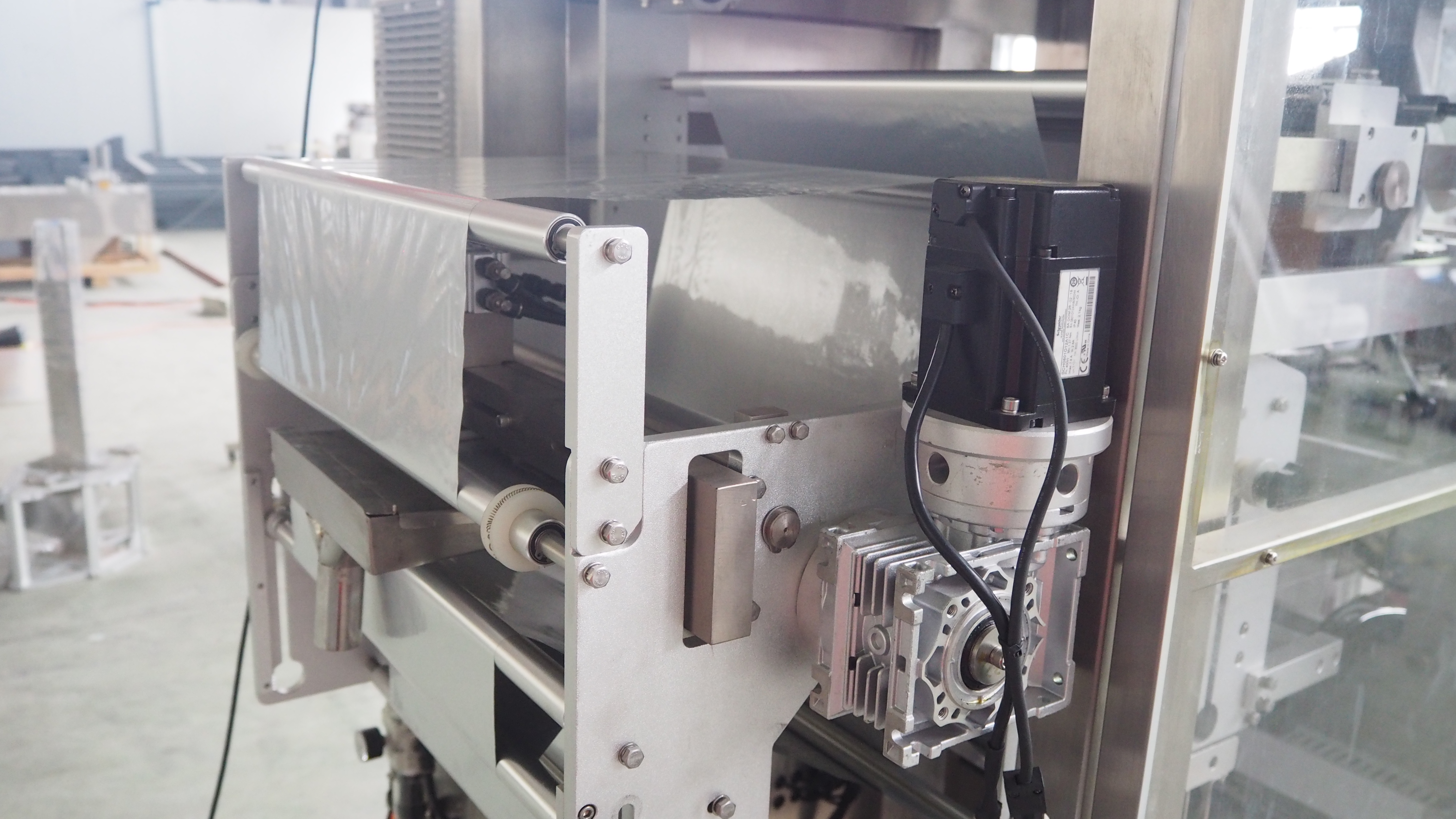

4. Film in roller can be locked and unlocked by air, convenient while change film.

1. The accuracy is within 3 grams, it could help you save the materials cost.

2. Sugar weigher max speed is 50 packs/min for 1kg weight, enjoy higher efficiency.

1. Flling products on vibrator feeder of Z bucket conveyor on floor, and it will be lifted on the top of mulihead weigher;

2. Multihead weigher will automatic weighing according to preset weight;

3. Preset weight products drop into bag former, and then packing film will be formed and sealed;

4. Finish package will be output to metal detector, if with metal, wil output signal to check weigher for relecting:

5. If without metal, it pass to check weigher. overlunder welight wll be rejected, qually weight pass to rotary table;

6. Products will get to rotary table, and worker put them into paper box.

How well does Smart Weigh meet the requirements and needs of its customers?

Customized service for customers:

Weighers tailored to the characteristics of the material: granules, powders, viscous pastes, flowing liquids, etc.

Provide the right closure packer according to the needs of the packaging: bag type, tray, bottle, etc.

Provide high precision / high efficiency / space saving packaging solutions according to customer needs

What is the payment method?

Direct T/T payment through bank account

Letter of credit payable on sight

How can the customer check the quality of the machine?

Smart Weigh will send you the photos and videos of the machine to check its operation before delivery. More importantly, customers are welcome to come to the site to inspect the machine.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine