A Complete Overview Of Powder Packing Machine

Streamlining Industrial Packaging Process

Industrial manufacturing covers a wide spectrum and effective packing of powdery products is a critical tool for production quality and hygiene as well as keeping manufacturer's efficiency and productivity high. Packing machines for powder have earned reputations as indispensable devices that give the option for automating the packaging which involves the processes of filling, sealing and labeling of the powdered products in different containers. This all-inclusive manual delves into various issues associated with/as regards powder packing machines: starting from their types and working principles, proceeding to applications, benefits, factors of their selection, terminations with the innovations that are led to this industrial automation field.

Understanding Powder Packing Machines: The Introduction

There a group of packing machines used for dust like substances called as powder packaging machines. They have served their purpose very efficiently by packing high number of powdered substances with high levels of accuracy. They help to transform how goods are packaged across the industries including pharmaceuticals, food and beverage, chemicals, cosmetics, and many others therefore. With assistance in doing powder products in their compartments and the sealing of, packaging machines for powder thus bring productivity, wastage reduction and consistent packaging quality.

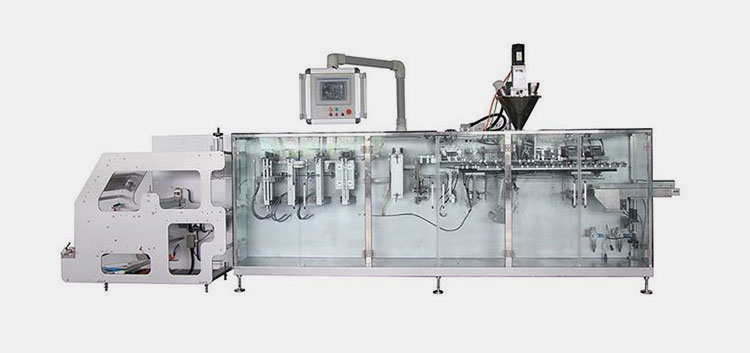

Integrated Powder Packaging Machine

In the case of integrated powder pouch packing machines, the working reciprocities of it depend on two things, which include the model and the design. These machines are multipurpose tools of production which not only fulfill numerous functions but also fit them into a single process to deliver accurate and time-saving results.

▲Auger Filler and VFFS System:

This process starts with manually unwinding a film that feeds into the tube forming part of the system. The auger filler meticulously measures and dispenses the precise quantity of powder into the forming tube then drop into bags. Following this, the sealing mechanism is sealed l and cut into individual packages, ensuring they are well-shaped and prepared for next packing stage.

▲Auger Filler and HFFS System:

The horizontal sachet and pouch form fill seal system uses film rolls in the form of pouches. The film material is fed into the machine by a roll that is rewound automatically when finished. The auger filler pipes the individual packaging with powder substance next the sealing and cutting it to final packets. This integrative technique ensures that the packaging is done at maximum efficiency in terms of usage, design and processing consistency.

▲Auger Filler and Pouch Packing System:

In the auger filler, the process of power into a hopper then a screw auger is completed by the pouch packing system. The auger system into the multi-compound pouch feeds the powder through them in predetermined quantities ensuring the correct proportions and filling, respectively. Having this integrated story-line ensures precision and reliability.

Working Principle of Powder Packing Machine

The working features of automatic powder packing machines differing according to their construction and model will be investigated. These machines, by designed to have many functions in one step, provide packaging powdered products accurately and precisely, instead of doing all these by manual ways. Below are the working principles of key integrated powder packing systems.

●Auger Filler and VFFS System:

This integrated pill processing system starts by reversing the film reel for a cylinder production. The auger filler loads powder accurately into the tube and then, the tube is sealed in succession along the longitudinal direction. After that, the sealed tube is sliced and set aside into bagged containers which were carefully packed.

●Auger Filler and HFFS System:

The horizontal form fill seal method uses the film roll for forming the intervention cups or sachets. After the auger fills the pouch, the powdered substances get poured in the auger and finally sealing and cutting are performed to slice the individual packets. Such an integrated process is the optimal solution involving packaging efficiency and consistency.

● Auger Filler and Pouch Packing System:

Through the help of a hopper and auger screw filler, the auger filler will place the powder using the hopper. To be more precise, the auger projects the powder evenly into ready-to-use pouches, which means that precise portions and filling process are maintained. This is achieved through this one step approach by ensuring that every detail is accounted for and no detail is left out.

Applications of Powder Pouch Packing Machine

Powder packing machines find extensive applications across various industries, including: powder sachet packing machines find extensive applications across various industries, including:

√Food Industry: Bags of spices, powdered baking mixes, nutritional drinks, coffee, and lots of nutritional supplements are packed.

√Pharmaceutical Industry: Selection of medications, vitamins, and powder-based supplements packaging.

√Chemical Industry: Packaging of the detergent powder, the pigments, the dyes and the chemical mixtures with special effects for which it is known.

√Nutraceutical Industry: One of the most commonly marketed nutritional products on the market is powdered protein powders, dietary buffers, and weight control supplements that are packaged in canisters.

Evolution of Powder Packing Equipment at a Glance

Powder packaging equipment offer numerous advantages that contribute to improved efficiency and product quality in industrial packaging operations:

◆Increased Productivity: Automation means less traditional skills needed, more tasks accelerated, and higher output of packages.

◆Precision and Accuracy: Sacks sealing machines guarantee a uniformed weight of product and protect it against damage during packaging, which leaves no space for giveaway.

◆Versatility: These machines are able to integrate with different kinds of powdered products, various packing styles, and the levels of production, setting the stage for their productive role in the manufacturing industry.

◆Hygiene and Safety: The libraries which are sealed and with no pollution ensure that the commodity does not get contaminated at its packaging stages.

◆Cost-Effectiveness: Through reduced material wastage and optimized packaging process, packing machines for powder are playing an pivotal role in the wider economic benefits to the manufacturers which leads to overall cost savings.

Key Considerations for Choosing a Powder Packaging Machine

Selecting the right packing machine for powder requires careful consideration of various factors to align with specific production requirements and operational need:

■Type of Powder: One could not probably tell the difference between different powders with different flow characteristics and handling needs. Go for a device with the features that match with the nature of your powdered product.

■Packaging Format: Establish what to choose the products packaging, such as, bags, pouches, sachet(s), bottles, or containers.

■Production Volume: Establish which machine is the best option by assessing the production capacity required and whether that machine can fulfil current and future demand levels.

■Filling Accuracy: For instance, how fine the degree of accuracy and precision that is desired needs to be considered when powdered products are being filled out, particularly in food and pharmaceutical industry.

■Maintenance and Support: A comprehensive support plan that includes after-sales service, spare parts availability, and technical support, will add value to the customer experience and assure delivery of high-performance level.

Future Trends in Powder Packing Technology

As technology continues to evolve, powder packaging equipments are poised to incorporate innovative features and capabilities that enhance efficiency, productivity, and sustainability in industrial packaging:

✔IoT Integration: IoT (Internet of Things) connectivity is the way towards proper monitoring out of place, predictive maintenance and data-driven insights related to packaging operations.

✔Advanced Material Handling: Rather than the approaching technological breakthroughs in material handling technology inspire more robust transport of challenging powders, thereby leading to improving amalgamated machine performance.

✔Enhanced Hygiene Standards: The cleaning gear which is installed in the machines which have the advanced features of cleaning and sterilization guarantee that the standards of hygiene and safety as required are strictly adhered to.

✔Automation and Robotics: At the same time robotic and automation technologies are integrated they help in achieving no only speed but also accuracy and reliability of powder packing.

Conclusion

Packing machines which are dedicated to powdering safety and efficiency are responsible for many of the industrial manufacturing processes by helping companies speed up and streamlining the packaging of powdered substances. Conversant with different types, working principles, applications, main advantages, factors to be considered on selection, and the future trends of powder packing machines, manufacturers stand to opt for informed choices which will slowly but surely result in better operational efficiency, product quality and hence competitiveness in the marketplace. To some extent, the world of powder packing technology continues to be governed by the advancements in the technological sphere as it simultaneously promises more intelligent solutions that will be able to cater for the impending industry trends.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine