VFFS Packaging Machine Working Principle

One of the most important equipment in the modern packaging lines is a vertical form fill seal machine. It assists brands in packing items fast, securely and uniformly regardless of snacks, non-food and powders.

In this guide, we will go through the functioning of the machine, the flow of production and the precautions required under various types of products. You will also get to know the fundamentals of maintenance and cleaning in order to ensure that the system remains effective and efficient. Read on to learn more.

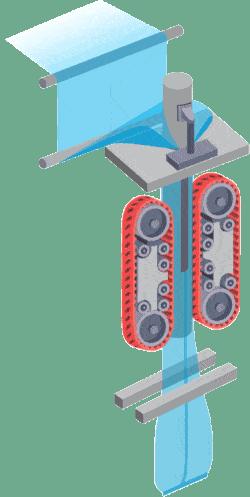

Working Principle of a VFFS Packaging Machine

A vertical form fill and seal machine creates a complete package from a roll of film and fills it with the right amount of product. Everything happens in one vertical system, which makes the machine fast, compact, and suitable for different industries.

The working cycle begins with film being pulled into the machine. The film is coiled around a forming tube and it makes the shape of a pouch. After forming the pouch, the machine then seals the bottom, fills the product and then seals the top. The process is repeated over and over at a high rate of speed.

Sensors help maintain accuracy in film alignment and bag length. Multihead weighers or auger fillers are weighing or dosing machines that are used with the VFFS packing machine to ensure that each package has the right amount of product. Due to automation, manufacturers receive consistent package quality and less labor is required.

Production Process Flow

The production process in a VFFS packing machine follows a clear and synchronized sequence. While machines vary in design, most systems use the same basic flow:

● Film Feeding: A roll of packaging film is fed into the machine. Rollers pull the film smoothly to prevent wrinkles.

● Film Forming: The film wraps around the forming tube and takes shape as a vertical pouch.

● Vertical Sealing: A heated bar creates the vertical seam that forms the body of the bag.

● Bottom Sealing: Horizontal sealing jaws close to create the bottom of the pouch.

● Filling the Product: The dosing system drops the exact amount of product into the newly formed pouch.

● Top Sealing: The jaws close the top of the pouch and the package is made complete.

● Cutting and Discharge: The machine cuts the single pouches and moves them to the next stage of the production line.

This flow keeps production steady and helps maintain high output rates. The result is cleanly sealed, uniform packages ready for boxing or further handling.

Precautions for Packaging Different Types of Products

A VFFS packaging machine can be applied in various industries but particular attention to each type of product is to be paid to ensure quality and safety. Here are the key precautions:

◆Food Products

Packaging of food should be done under clean and controlled conditions. Keep these points in mind:

● Apply food-level films and sanitary machine components.

● The sealing temperature should be maintained to avoid leakage.

● The dosing area is to be kept clean to prevent contamination.

● Make sure that the product does not get stuck in the bag.

Food producers also use metal detectors or check weighers with their VFFS packaging machine to improve safety and accuracy.

◆Powder

Certain powders are dusty and they can affect seals.

Important precautions include:

● Use dust-control systems and enclosed filling zones.

● Choose the appropriate filling system, such as an auger filler when filling powders.

● A tilt to the sealing pressure assists in guaranteeing that no powders are lodged in the seams.

● Keep the humidity low to avoid clumps.

The following are measures that are helpful in maintaining the seals clean and properly filled.

◆Pharmaceuticals and Chemicals

These are products whose safety standards must be followed strictly. Manufacturers should:

● Keep the surroundings around the dosing clean and sterile.

● Use anti-static film when necessary.

● Ensure accurate dosing to meet regulatory requirements.

● Prevent chemical residue from contacting sealing bars.

A vertical form fill seal machine used in this sector often includes sensors, extra guarding, and enhanced cleaning features.

◆Non-Food Items

Non-food products like hardware, small parts, and plastic components can have sharp edges or uneven shapes.

Precautions include:

● Choosing thicker or reinforced film.

● Ensuring the product does not damage the sealing jaws.

● Adjusting bag length and shape for a better fit.

● Using stronger seals for heavy items.

These steps help protect both the product and the machine.

Maintenance and Cleaning Requirements

The maintenance of a VFFS packaging machine keeps it running and increases its lifespan. The system deals with film, product, heat and mechanical movement and so regular checks are important.

Here are the main tasks:

● Daily Cleaning: Remove product residue, especially around the filling area and forming tube. For dusty products, clean the sealing bars often.

● Check Sealing Components: Inspect sealing jaws for wear. Worn parts can cause weak seals or burned film.

● Inspect Rollers and Film Path: Make sure rollers pull the film evenly. Misaligned rollers can lead to crooked seals or film tearing.

● Lubrication: Apply lubrication on moving parts as scheduled by the manufacturer. Excess lubrication around sealing points should be avoided.

● Electrical Components: Check sensors and heating elements. Failures in these areas can cause poor film tracking or weak seals.

● Dosing System Calibration: Checking of weighing or volumetric systems should be frequent in order to have a proper fill. This is particularly true with powders and pharmaceuticals.

These measures are useful in ensuring regular performance of any vertical form fill and seal machine.

Final Thoughts

A VFFS packing machine is a multifunctional and reliable solution to most industries. It is best suited to the companies that require speed, accuracy and reliable operation when it comes to making packages, filling, and sealing them in a single motion. Whether it is food, powders, pharmaceuticals or non-food products, knowing the working principle of the machine will enable you to have an efficient production line.

In case you are willing to upgrade your packaging process, consider the entire range of automated systems offered by Smart Weigh. Our innovative solutions will allow you to work more productively and at a high quality level. Get in touch with us now to find out more or request personalized support for your production line.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine