Applications For 10 Head Multihead Weigher in Automation Packaging

Have you ever thought how snack bags are full of a perfect volume of chips? Or how is it that the pouches with candy are filled so quickly and neatly? The secret lies in smart automation, especially machines like the 10 Head Multihead Weigher.

These compact powerhouses are changing the packaging game across industries. In this article, you'll learn how the 10 head multihead weigher works, where it's used and why it’s a smart choice for faster, easier packaging. Read on to learn more.

How the 10 Head Multihead Weigher Streamlines Automated Processes

At its core, a 10 head multihead weighing machine is built to deliver accuracy and speed. It works by weighing products across ten separate “heads” or buckets. Each head gets a portion of the product, and the machine calculates the best combination to reach the target weight; all in just a split second.

Here's how it makes automation smoother:

● Fast Weighing Cycles: Each cycle is completed within milliseconds, helping boost output significantly.

● High Accuracy: No more product giveaway or under-filled packs. Every pack hits the right weight.

● Continuous Flow: It will provide a continuous flow of the product into the next packaging process.

The machine is time-saving, waste-free and consistent. It makes work fast and does it right, whether packing nuts or cereal or frozen veggies.

Packaging Applications Across Industries

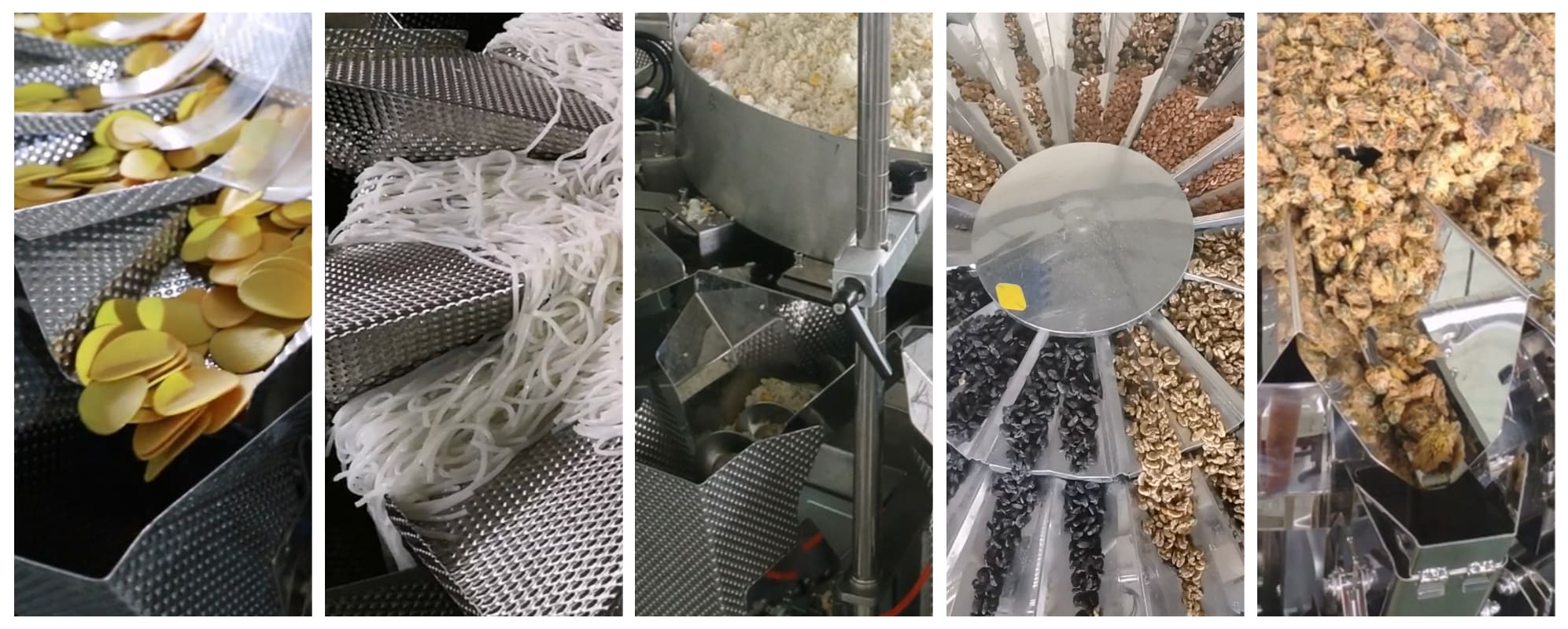

The 10 head weigher isn't just for snacks. It’s surprisingly versatile! Let's walk through a few industries that benefit big from this smart tech:

▶Food and Snacks

● Granola, trail mix, popcorn, and dried fruits

● Hard candies, gummy bears, and chocolate buttons

● Pasta, rice, sugar, and flour

Thanks to its precision, each portion is accurate, helping brands keep their promises to customers.

▶Frozen and Fresh Produce:

● Mixed vegetables, frozen fruits

● Leafy greens, chopped onions

It can work in chilled environments and even has models built to handle frosty or damp surfaces.

▶Non-Food Products:

● Small screws, bolts, plastic parts

● Pet food, detergent pods

Don’t think this is just a “food machine.” With SmartWeigh's customization, it handles all kinds of granular or irregular-shaped items.

Integration with Other Packaging Machines

A 10 head weigher rarely works alone. It's part of a packaging dream team. Let’s see how it syncs with other machines:

● Vertical Packing Machine: Also known as VFFS (Vertical Form Fill Seal), it forms a pillow bag, gusset bags or quad sealed bags from roll film, fills it, and seals it all in seconds. The weigher drops the product in right on time, ensuring zero delays.

● Pouch Packing Machine: Perfect for kinds of premade pouches, such as stand-up pouches and zip-lock bags. The weigher measures the product, and the pouch machine ensures the pack looks great on store shelves.

● Tray Sealing Machine: For ready meals, salads, or meat cuts, the weigher drops portions into trays, and the sealing machine wraps it up tight.

● Thermoforming Packaging Machine: Perfect for the vacuum-packed cheese block or sausage. The weigher makes sure that they put carefully measured amounts in the individual thermoformed cavity before sealing.

Each setup reduces the need for human touch, improves hygiene, and speeds up production, big wins all around!

Key Features That Add Value in Automation

So, why pick a 10 head multihead weigher over other machines? Simply, it’s packed with smart features that make your workday easier and your packaging line run more smoothly. Let’s take a look:

◆Compact Design

Not every factory has endless floor space and this machine gets that. The 10 head weigher is built to be small but mighty. You can tuck it into tight spots without needing to tear down walls or move other equipment. It’s perfect for small and mid-sized businesses looking to level up without a big construction job.

◆Touchscreen Interface

No one wants to spend hours learning how to use a machine. That’s why the touchscreen panel is a total game-changer. It’s super easy to use, just tap and go! You can adjust weight settings, switch products, or check performance with just a few touches. Even beginners can handle it with confidence.

◆Smart Self-Diagnostics

Let's be honest, machines can act up sometimes. But this one makes it easy to figure out what's wrong. If something isn’t working right, the machine gives you a clear message. No guessing, no need to call an engineer right away. You see what’s wrong, fix it fast, and get back to work. Less downtime = more profit.

◆Modular Construction

Cleaning or fixing machines can be a real headache, but not here. The 10 head multihead weighing machine is a modular machine implying that every component can be conveniently disassembled and washed without having to dismount the entire system. That is a major victory for hygiene particularly in the food industry. And when one component requires replacement, it does not switch off the entire system.

◆Fast Recipe Changeover

Need to switch from packing nuts to candy? Or from screws to buttons? No problem. This machine makes it simple. Just tap in the new settings, swap a few parts if needed, and you’re back in business. It also remembers your product recipes, so there's no need to reprogram every time.

These little upgrades add up to smoother workflows, less downtime, and happy production teams.

Smart Weigh Pack's Multihead Weigher Advantages

Now let’s talk about the star of the show, Smart Weigh Pack'10 head multihead weighing machine. What sets it apart?

✔1. Built for Global Use: Our systems are used in 50+ countries. That means you’re getting tried-and-tested reliability.

✔2. Customization for Sticky or Fragile Products: Standard multihead weighers struggle with things like gummies or delicate biscuits. We offer special models with:

● Teflon-coated surfaces for sticky foods

● Gentle handling systems for breakable items

No crushing, sticking, or clumping, just perfect portions every time.

✔3. Easy Integration: Our machines are plug-and-play ready with other automated systems. Whether you have a VFFS line or a tray sealer, the weigher slides right in.

✔4. Top Support and Training: Smart Weigh Pack doesn't leave you hanging. We offer:

● Fast-response tech support

● Setup help

● Training to get your team up to speed

That’s peace of mind for any factory manager.

Conclusion

The 10 heads multihead weighing machine is not a scale, but a powerful, flexible, robust, high-speed solution to automation of the entire packaging process. Whether it is food or hardware, it provides accuracy, speed, and consistency per cycle.

The high-tech and rock-solid support of Smart Weigh Pack makes it a best choice when it comes to businesses that want to take their production lines to the next level. Thus, when you are determined to have an efficient and quality production, then this is the machine you need in your packaging line.

Smart Weigh 10 Head Multihead Weigher Series:

1.Standard 10 Head Multihead Weigher

2.Accurate Mini 10 Head Multihead Weigher

3.Large 10 Head Multihead Weigher

4.Screw 10 Head Multihead Weigher For Meat

FAQs

Question 1. What is the main benefit of using a 10 head weigher in packaging?

Answer: The biggest benefit is its speed and accuracy. It weighs products in split seconds and ensures each pack has the exact target weight. That means less waste, more productivity.

Question 2. Can this weigher handle sticky or fragile products?

Answer: The standard version may not be ideal for sticky or breakable items. But Smart Weigh offers customized models specially designed for such products. They reduce sticking, clumping, or breakage.

Question 3. How does the weigher integrate with other machines?

Answer: It's designed to work smoothly with vertical form fill seal machines, pouch packing systems, tray sealers, and thermoforming machines. Integration is simple and efficient.

Question 4. Is the system customizable for different production lines?

Answer: Absolutely! Smart Weigh Pack offers modular systems that can be tailored to your production needs from product type and pack style to space and speed requirements.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine