Everything to Know About Salad Packaging Machine

Produce like salads needs to be processed efficiently and with quality in mind. In recent years, companies have begun using salad packaging machines for convenience in the production of prepared ready-to-eat salads. These types of machinery remove the obstacles to salad package production and enhance hygiene, speed, and aesthetics so far that even the most appetite-challenging salads dry out. In this article, we will review everything that you should know regarding salad packing machines.

What is a Salad Packaging Machine?

A salad packaging machine is specialized equipment. It is meant for packing salads into bags, bowls, containers, etc. Such machines perform delicate tasks without crushing ingredients like leaf greens, vegetables, and dressings. Different types of salad packing machines are available. Salad packing machines come in various sizes and configurations. These machines are suitable for everything from small businesses to large-scale production facilities. The design of these machines focuses on efficiency, accuracy, and user-friendliness.

How Does a Salad Packing Machine Work?

The working process of a salad packing machine is cumulatively performed to promote effective packing.

✔Loading: First, Ingredients used to make salad are fed into the machine. This may be either manual or automatic depending on the model. Often in packing the ingredients sourced from the farms are sorted to eliminate any unwanted produce.

✔Calibration: Precise measurements are made in regard to the portioning so that such portions are included in the packages more than once. This is one of the steps which guarantees that as such the packages or pouches attract customers.

✔Dispensing: Bags, bowls or containers can be filled with salad. In most advanced models, it is possible to fill in a mix of ingredients rather than the salad only.

✔Closing: The filled bags are then tightly closed using steam or even machine pressure. This ensures that the salads are not wasted and further preserves them from being contaminated.

✔Labeling: Information about the products packed in the various packages is applied automatically by labeling machines. This then improves the tracing and compliance of regulations concerning the safety of food.

How Can Salad Packing Help Your Business?

Investing in a salad packing machinery offers several advantages that can significantly impact your business's bottom line:

1. Increase Efficiency

Automation increases the speed of the packaging function making it possible to produce more with less labor. Unlike manual packing, salad packaging machines can work round the clock leading to increased production levels. Therefore, such efficiency enables businesses to satisfy demand- especially during peak periods.

2. Consistency

One of the greatest advantages of a salad packaging machine is uniformity. A machine takes care of the portion sizes and the packaging quality which is very important for pricing and overall customer satisfaction. Standardized packaging helps protect your company’s image as well as develop customer loyalty.

3. Reduce Waste

Salad packing machines minimize food waste, contributing to sustainability efforts. Less waste means more profit, as businesses can maximize the use of their ingredients.

4. Enhance Shelf Life

Freshness and the life of salads is maintained through the appropriate sealing of the packs. The packaging machines for salads work in such a way that there is no access to air and dirt. This makes sure that the products remain appealing to the eye of the customers for a longer time than usual. This is critical for companies intending to market their salads through retail outlets.

5. Branding Opportunities

Companies are looking at customized packaging to improve their brand image and draw in more consumers. When it comes to salad packing machines, companies can add logos, color and other branding features easily in their packaging. Packaging with nice designs can set your product apart from others on the shelf and grab the interest of potential buyers.

6. Scalability

The machines have been built with a flexible capacity that means that the production will not be stalled regardless of the majority of the salads being packaged. Most of these machines have various settings.

7. Improve Hygiene

Salad packing machinery are manufactured to ensure cleanliness within the packaging of salad hence minimizing the chances of food contamination. A lot of procedures that involve the handling of the product are made automatically in the present day where safety is the main purpose.

How Do You Maintain a Packaging Machine?

Regular maintenance is essential for ensuring the longevity and efficiency of a salad packaging machine. Here are some key maintenance tips to keep your machine in top condition:

1. Regular Cleaning

You have to clean the machine after every use to avoid any accumulation of waste as well as maintain cleanliness. This involves washing all surfaces, conveyors, and any sealing adherent materials. Most of the machines are provided with detachable components that always help ensure that they are cleaned and no remnants are left.

2. Lubrication

It is essential to apply lubricants on any moving parts ( as suggested by the manufacturer) to reduce friction complications. Timely lubrication helps to save on costs associated with repairs or breakdown of operations which can be frustrating.

3. Inspect Components

Always assess for damages on the parts especially in cover belts, or seals because these parts can sustain significant damage. Taking care of worn-out or damaged elements will help avoid bigger complications later.

4. Calibrate Settings

Periodically calibrate the machine to ensure accurate measurements and optimal performance. Calibration helps maintain the quality and consistency of your packaged salads.

5. Follow Manufacturer Guidelines

Utilize the maintenance schedule as well as follow the measures that have been provided in the manual. Special cares are also normally given by the manufacturers of the equipment which would help in providing better ware and increased performance of the machine.

6. Staff Training

Make sure that machine operators undergo appropriate training which includes operating and care of the tools. Not only does this improve operations, but it also gives operators the ability to foresee problems that could arise and prevent anyone from being hurt.

What to Look for Before Choosing The Best Salad Packaging Machine?

When choosing the best salad packing machinery, several key factors should be considered. You have to ensure it meets your specific needs and enhances your operational efficiency. Here’s a comprehensive guide on what to look for:

1. Type of Packaging

Format Compatibility: Determine whether you need a machine that can handle bags, bowls, clamshells, or other packaging formats. Make sure the machine you choose is versatile enough for your product range.

Size and Weight: Consider the size and weight of the salads you plan to package. Ensure the machine can accommodate the specific dimensions and weight limits.

2. Automation Level

Manual vs. Automatic: Make up your mind as to whether you want a machine that is manual, semi-automatic or fully automatic. A fully automatic machine may save time and effort but it can be expensive.

Integration with Existing Systems: Check if the machine can be integrated with your current production line or if it requires additional modifications.

3. Speed and Efficiency

Output Rate: Examine how fast the machine is when it comes to packing the goods. It is imperative that production rates are higher in order to satisfy demands.

Cycle Time: Consider the time it takes for the machine to complete a packaging cycle, including filling, sealing, and labeling.

4. Ease of Use

User-Friendly Interface: You have to buy those machines that come with intuitive controls and easy-to-understand settings. This will minimize training time and operational errors.

Quick Changeovers: Machines that allow for fast adjustments between different packaging formats or sizes can enhance productivity.

5. Maintenance and Support

Ease of Maintenance: It is essential to select a machine, which has a simple structure so that it can be easily cleaned and maintained. Observe if the machine has detachable parts for better access.

Manufacturer Support: Examine the customer satisfaction policy of the manufacturer. This includes. Potential for the availability of spare parts and any other kind of customer support.

Material Quality: Select devices that are constructed from good material that can resist daily stress and wear and tear in a bid to promote durability.

Build Quality: Assess the construction and design of the machine for robustness and reliability.

6. Hygiene and Food Safety

Compliance with Regulations: Make sure to check whether the machine meets local and international food safety standards, such as NSF, FDA, or CE certifications.

Hygienic Design: Machines must minimize contamination risks and offer smooth surfaces and easy-to-clean components.

7.Cost and ROI

Determine your budget and consider the overall cost of the machine, including installation and any additional features.

Are you looking for affordable and efficient automated salad packaging, machines? Smart Weigh offers advanced salad packaging solutions for salads and fresh produce. It designed to meet the highest international standards. Our machines are CE-certified, ensuring safety, reliability, and precision in packaging operations.

Conclusion

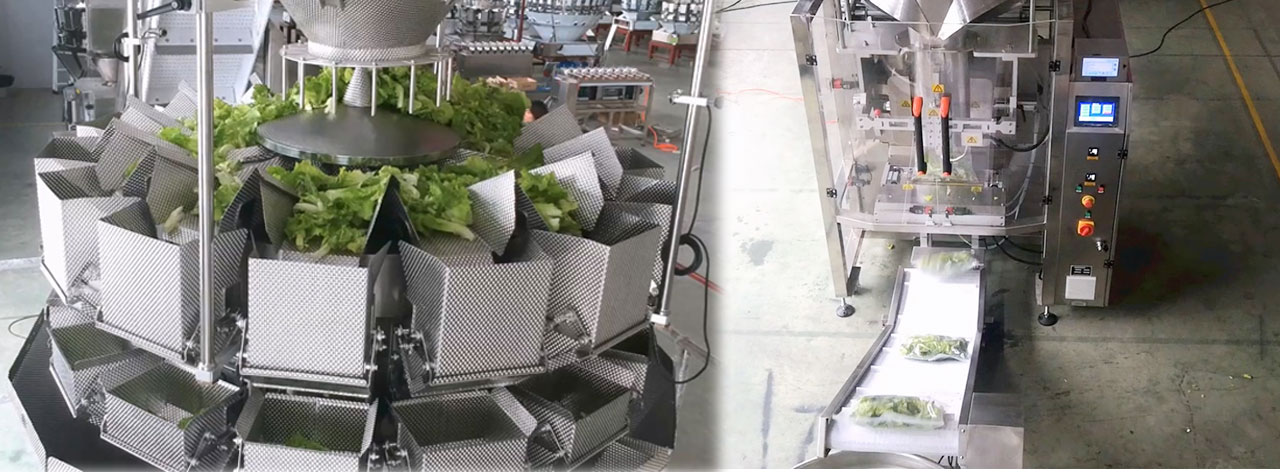

The Weighing Packaging Machine for Pillow Bags is a proficient system for the packing of a number of fruits and vegetables such as salads, lettuce, and garlic among others. This system is equipped with a multihead weigher and vertical form-fill-seal machine. It can be used to automatically make pillow bags from sheeting roll in a way that is safe and cost-efficient.

Our Salad Container Filling Machines accept many container types including plastic trays, clamshells, cups and even biodegradable containers. This adaptive machine can be modified so that it can handle various salad types and containers without affecting production line productivity and efficiency.

For companies which plan to invest in a salad packaging machine, the results will be quite impressive as it will eliminate unnecessary work processes while optimizing performance and maintaining high standards of quality.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine