How To Improve Efficiency And Reduce Downtime With VFFS Machines

VFFS machine, or vertical form fill seal machines, are widely used packaging equipment in various industries. They assist in increasing the packaging flow yet maintain product quality and homogeneity.

Suppose only we tackle these issues and gain practical tips on doing things better and faster. In that case, first-hand information can go a long way in managing various concerns of enhancing operations’ efficiency and minimizing downtimes.

Similarly, essential solutions include improving all parameters and conditions related to machine settings or regular maintenance. The VFFS technologies of Smart Weigh bring advancements in packaging operations to a new edge.

Jump in to learn more about vertical form fill seal machines and how they can revolutionize packaging.

Understanding VFFS Machines

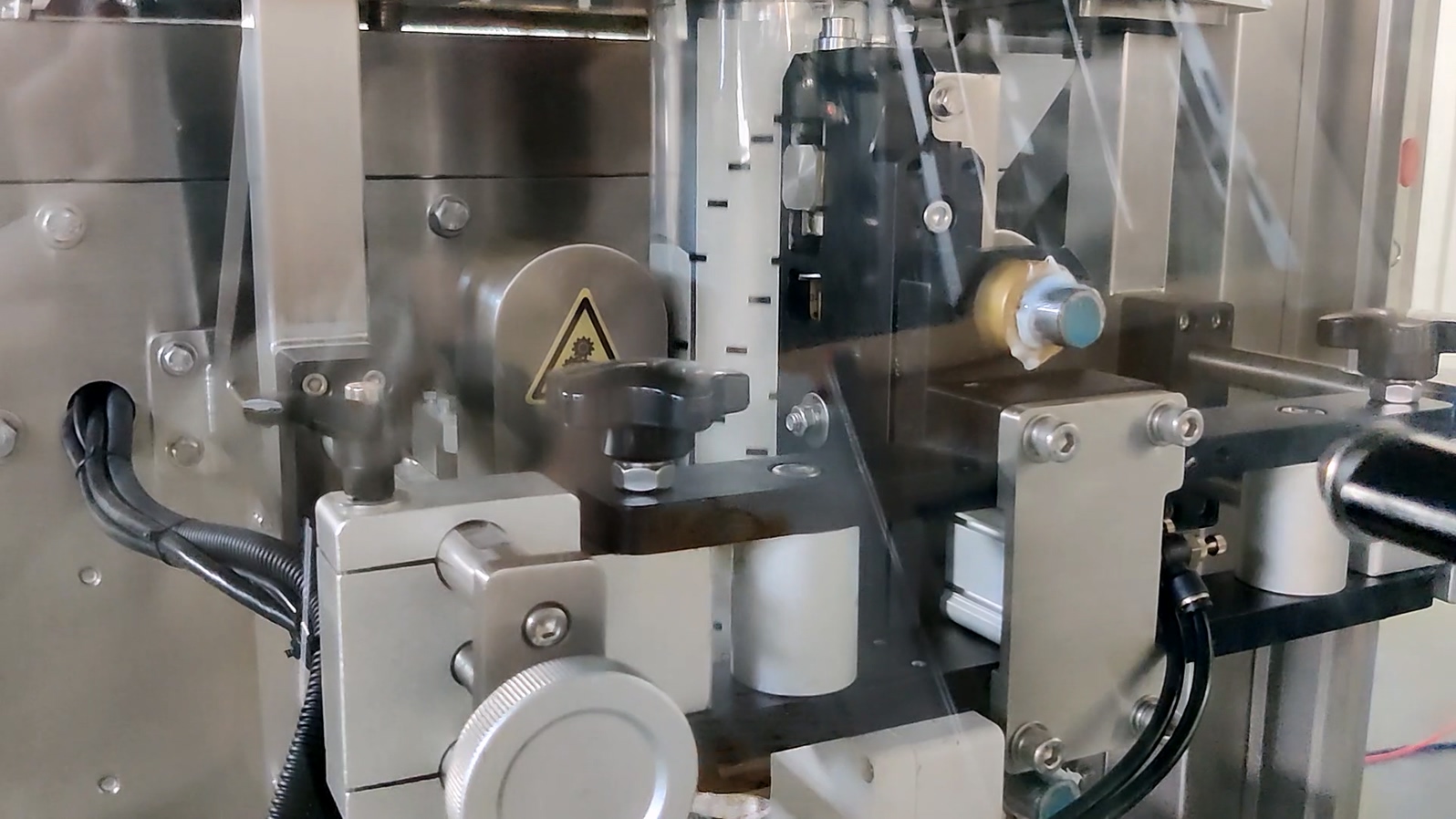

Vertical Form Fill Seal (VFFS) machines are specific form-fill-seal machines that package products. It is a vertical continuous forming, filling, and sealing method for creating many products simultaneously.

They assist in enclosing products rapidly and without much hustle. The machine can employ a roll of film in creating the bags or pouches that they fill with the product and seal. First, this automatic process shortens the packaging time, and second, it creates identical and quality packages.

Components Of A Vertical Form Fill And Seal Machine

Many components make up a vertical packaging machine to successfully finish packaging. These include:

✔Film Roll: The source material used to make the packaging.

✔Former: Shapes the flat film into a tube.

✔Product Filler: Put the product into the formed tube.

✔Sealing Jaws: Heat-seal the package's top and bottom to seal it properly.

✔Cutting Mechanism: Cuts the sealed package to separate it from the next one.

✔Control Panel: Allows operators to set and monitor the machine's settings.

✔Sensors: Ensure correct alignment and operation throughout the process.

Benefits Of Using Vertical Form Seal Machines

The advantages of using vertical form fill seal packaging machines make them popular.

●Enhanced Efficiency In The Packaging Process.

VFFS packing machines enhance packaging through automated form, fill, and seal techniques. This automation eliminates the time to package the products and ensures production goes on faster.

In this case, one can sell more goods at a certain period and optimize production volume to guarantee good quality.

●Reduction In Packaging Material Waste.

Vertical form fill seal machine are always properly managed to avoid the wastage of the films being used in packaging. Some are updated so that only the right measure of packaging material required for a specific product is used with benefits such as cutting costs.

This is a more efficient and environmentally friendly choice and is most beneficial to you in the long run.

●Flexibility In Packaging Different Product Types.

Another aspect of VFFS machines is the versatility of this type of equipment when dealing with many types of products.

These packing machines can, therefore, be easily modified to fit into packing materials that may be powders, granules, liquids, or solids. This flexibility makes them ideal for businesses that provide many goods and services related to various fields and industries.

●Consistent And High-Quality Sealing.

Meeting the packaging needs is a concern, and vertical form fill and seal machines do so consistently. They give dependable and superior-quality seals to every package to help people maintain their products' quality, freshness, and safety.

Continuity of the sealing decreases potential leakage or contamination of products, creating protection for your products.

Increasing Efficiency With VFFS Machines

A few measures can help increase the efficiency of vertical form filling machines. For beginners, adjust the machine settings, such as temperature and speed, depending on the product and packaging material used.

Proper maintenance and calibration of the machine ensure that it operates optimally, thus reducing breakdowns. Well-trained operators can easily identify faults and make the necessary corrections within a very short time.

Last but not least, implementing automation and IoT makes it possible to monitor processes, make data-based decisions, and minimize downtime. Therefore, you can derive maximum value from your vertical form seal machines by concentrating on these areas.

Minimizing Downtime With Vertical Form Fill Seal Packaging Machines

Reducing cycle time on vertical form fill seal packaging machine is important to prevent disruptions. You need to employ predictive maintenance to detect problems before they bring about system failure.

Using quick-changeover methods helps you save time changing products. High-quality components mean lower failure rates and longer between servicing or replacing the parts.

Finally, a maintenance checklist must be created to ensure that the machine is checked and serviced at the right time. With these strategies in mind, you can minimize disruptions and maintain continuous operation of your vertical form fill seal machines.

Smart Weigh’s VFFS Solutions

Vertical Form Fill Seal (VFFS) machines to help increase packaging performance. These solutions are part of their complete range of packaging solutions, which comprises multihead weighers and linear weighers.

Ideal for snacks, dried fruits, frozen foods, nuts, salads, meats, and ready-to-eat meals, the VFFS packing machines offered by Smart Weigh are suitable for various sectors. Today, Smart Weigh has installed over 1,000 systems in over 50 countries, making it the packing industry’s go-to provider.

The Final Say

VFFS stands for vertical form fill and seal machines, which are essential to advancing packaging processes. Maintenance downtime can be prevented using the predictive maintenance method, while quick-changeover enables the business to continue its operations.

Among the best VFFS machines, Smart Weigh has what you need. Offering high-quality packaging systems to suit various sectors.

Vertical form fill seal machines are versatile in accommodating different products and are considered eco-friendly regarding the amount of material used. Adopting these technologies enables organizations to achieve high-quality sealing and performance while meeting production requirements proficiently.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine