A Practical Guide to Checkweighers

In today's manufacturing landscape, maintaining product quality and compliance is crucial. Checkweighers play a vital role in this process by ensuring that each product meets specified weight criteria. Smart Weigh offers a range of innovative solutions designed to enhance your production line's efficiency and accuracy. This guide delves into the world of checkweighing, highlighting the processes, technical specifications, applications, compliance standards, and benefits of Smart Weigh's check weigher machine.

What are the Types of Check Weighers?

Static Checkweighers

Measure products that are stationary on the weighing part. These are ideal for manual operations or low-speed production lines where precision is critical, but speed is not a primary concern.

Dynamic Checkweighers

These weigh products as they move along a conveyor belt. Dynamic checkweighers are suitable for high-speed, automated production lines, ensuring continuous operation and minimal interruption.

Checkweighing Production Process

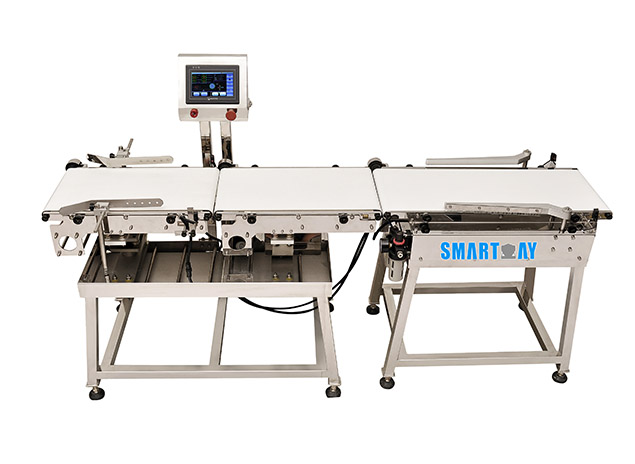

The standard checkweigher has 3 parts, they are infeed, weighing and outfeed part.

Infeed

The process begins at the infeed, where products are automatically directed into the check weigher machine. Smart Weigh’s static and dynamic checkweighers handle a variety of product shapes and sizes, ensuring a seamless transition and maintaining high throughput rates.

Weighing

At the core of checkweighing is precise measurement. Smart Weigh high speed checkweigher utilize advanced load cells and high-speed processing to deliver accurate results. For instance, the SW-C220 model offers high accuracy in a compact form factor, while the SW-C500 model caters to larger operations with its higher capacity and speed.

Outfeed

After weighing, products are sorted based on their compliance with weight specifications. Smart Weigh's systems feature sophisticated rejection mechanisms, such as pushers or air blasts, to efficiently remove non-compliant products. The combined metal detector and checkweigher model further ensures that products are both weight-compliant and contaminant-free.

All Our Check Weighing System Specification

As a professional automatic check weigher manufacturer, Smart Weigh provides a range of check weighers tailored to different production needs:

Standard checkweigher

SW-C220 Checkweigher: Ideal for smaller packages, offering high accuracy in a compact design.

SW-C320 Checkweigher: standard model for most of products including bags, box, cans and others.

SW-C500 Checkweigher: Suited for higher capacity lines, providing rapid processing speeds and robust performance.

| Model | SW-C220 | SW-C320 | SW-C500 |

| Weight | 5-1000 grams | 10-2000 grams | 5-20kg |

| Speed | 30-100bags/min | 30-100bags/min | 30 box /min depends on product feature |

| Accuracy | ±1.0 grams | ±1.0 grams | ±3.0 grams |

| Product Size | 10| 10 | 100 | |

| Mini Scale | 0.1 gram | ||

| Weigh Belt | 420L*220W mm | 570L*320W mm | Width 500 mm |

| Reject System | Reject Arm/Air Blast/ Pneumatic Pusher | Pusher Roller | |

High Speed Checkweigher solutions

This type, which incorporates Korean weighing technology, has a unique design that allows dynamic scales to operate with more precision and speed.

| Model | SW-C220H |

| Control System | Mother board with 7" touch screen |

| Weight | 5-1000 grams |

| Speed | 30-150 bags/min |

| Accuracy | ±0.5 grams |

| Product Size | 10 |

| Belt Size | 420L*220W mm |

| Rejection System | Reject Arm/Air Blast/ Pneumatic Pusher |

Combined Metal Detector and Checkweigher

This dual-function system ensures both weight accuracy and contaminant-free products, making it perfect for food and pharmaceutical applications.

| Model | SW-CD220 | SW-CD320 |

| Control System | MCU & 7" touch screen | |

| Weight Range | 10-1000 grams | 10-2000 grams |

| Speed | 1-40 bags/min | 1-30 bags/min |

| Weighing Accuracy | ±0.1-1.0 grams | ±0.1-1.5 grams |

| Detect Size | 10| 10 | |

| Mini Scale | 0.1 grams | |

| Belt Width | 220mm | 320mm |

| Sensitive | Fe≥φ0.8mm Sus304≥φ1.5mm | |

| Detect Head | 300W*80-200H mm | |

| Reject System | Reject Arm/Air Blast/ Pneumatic Pusher | |

Applications

Check weigher machine are versatile tools used across various industries. In the pharmaceutical sector, they ensure each dose meets regulatory standards. In food and beverage production, they prevent overfilling and underfilling, maintaining consistency and reducing waste. Logistics and manufacturing industries also benefit from the reliability and precision of Smart Weigh check weighers.

Benefits

The advantages of using Smart Weigh automatic check weighers are numerous. They improve accuracy, reduce product giveaway, and enhance overall production efficiency. By integrating these systems into your production line, you can achieve higher throughput and better quality control.

FAQ

1. What is a checkweigher?

Checkweighers are automated systems used to verify the weight of products in a production line.

2. How does a checkweigher work?

They operate by weighing products as they move through the system, using advanced load cells for precision.

3. What industries use check weighers?

Pharmaceuticals, food and beverage, logistics, and manufacturing.

4. Why is checkweighing important?

It ensures product consistency, compliance, and reduces waste.

5. How to choosing the right high precision checkweigher?

Consider factors like product size, production speed, and specific industry requirements.

6. Check weigher machine technical specifications

Key specs include speed, accuracy, and capacity.

7. Installation and maintenance

Proper setup and regular maintenance are crucial for optimal performance.

8. Checkweigher vs. traditional scales

Check weigher machine offer automated, high-speed, and precise weighing compared to manual scales.

9. Smart Weigh check weighers

Detailed features and benefits of models like SW-C220, SW-C320, SW-C500, and the combined metal detector/checkweigher.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine