Automatic Nuts Dried Fruits Packaging Machine Line | Smart Weigh

Vertical packaging machines for nuts dried fruits.The dry fruits packing machine is capable of automatically scaling to fill and package dried fruits in custom premade bags. Automatic dry fruits packing machine for nuts and dried fruits,aslo can be used to pack various solid materials, such as beans, puffed food, potato chips, pistachios, peanuts, jelly, preserves, walnuts, almonds etc. Our dried fruit packaging machine can pack different bag widths and net weights. The width of the laminate roll of bags changes as the bag width changes, and the shape and size of the bag forming chute changes accordingly.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Automatic Dried Fruits Packaging Machine

The dried fruit and nuts packaging solution is more than just a piece of equipment; it’s a testament to the innovation driving the food packaging industry forward. For businesses looking to enhance their packaging efficiency, maintain high quality, and meet the dynamic production demands of the market, this dry fruit packing machine is not just an investment but a step into the future of food packaging. The dried fruit packaging machine is a sophisticated and efficient solution designed to streamline the packaging process of various dry fruits. This automated system excels in precision, ensuring accurate weighing and packaging to maintain product integrity. Equipped with advanced technology, these machines offer customizable packaging options, allowing businesses to meet specific size and weight requirements. The user-friendly interface facilitates easy operation, and the high-speed capabilities enhance productivity in packaging operations. Additionally, many dry fruit packing machines are designed to maintain the freshness and quality of the products, incorporating features such as vacuum sealing and nitrogen flushing. This technology not only extends the shelf life of the dry fruits but also enhances their overall presentation, making the Dry Fruit Packing Machine an essential asset for food processing and packaging industries.

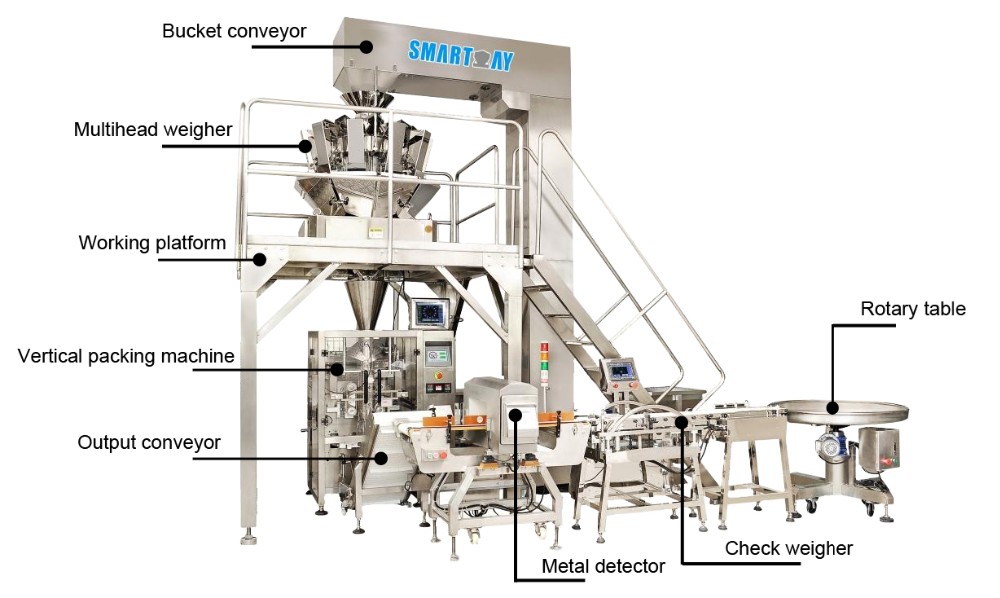

Dried Fruit Packaging Machine List & Working Procedure:

1. Bucket conveyor: feed product to multihead weigher automatically;

2. Multihead weigher: auto weigh and fill products as preset weight;

3. Working platform: stand for multihead weigher;

4. Vertical packing machine: auto make bags and pack products as preset bag size;

5. Output conveyor: convey finished bags to next machine;

6. Metal detector; detect if there is metal in bags for food safety;

7. Checkweigher: auto check bags weight again, reject overweight and overlight bags;

8. Rotary table: auto collect finished bags for next procedure.

Nuts Packaging Machines are pivotal in the food packaging industry, offering a comprehensive solution for efficiently packaging various nuts. Crafted with high-quality materials, these machines ensure durability and compliance with hygiene standards. Equipped with advanced performance features like multi-head weighers and precision dosing, they guarantee accurate and consistent packaging, accommodating different nut types and sizes. The user-friendly interfaces facilitate easy operation and swift product changeovers. Automatic dry fruits packing machine is specifically designed to pack different types of nuts and dry fruits efficiently and hygienically. Including Almonds, Cashews, Pistachios, Walnuts, Peanuts, Hazelnuts, Pecans, Macadamia Nuts, Trail Mix, Raisins, Dried Apricots, Dates, Dried Figs, Prunes, Dried Cranberries, Dried Mango, Dried Pineapple, Dried Papaya, Dried Berries (like Goji Berries, Blueberries), Sun-dried Tomatoes (though not a fruit in the traditional sense, they are often processed in similar facilities)

The advantages of nuts packaging machines lie in their ability to enhance productivity by minimizing manual labor, reducing packaging time, and ensuring uniform packaging quality. While primarily used for nuts and dry fruits, this nuts packaging machine could potentially be adapted for other similar food items such as:

* Seeds (like pumpkin seeds, sunflower seeds)

* Granola and trail mix components

* Small confectionery items (like chocolate-covered nuts or fruits)

* Specialty snack items

Model | SW-PL1 |

Weighing Range | 10-2000 grams |

Bag Size | 120-400mm(L) ; 120-400mm(W) |

Bag Style | Pillow Bag; Gusset Bag; Four side seal |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 20-100 bags/min |

Accuracy | + 0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5L |

Control Penal | 7" or 10.4" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 18A; 3500W |

Driving System | Stepper Motor for scale; Servo Motor for bagging |

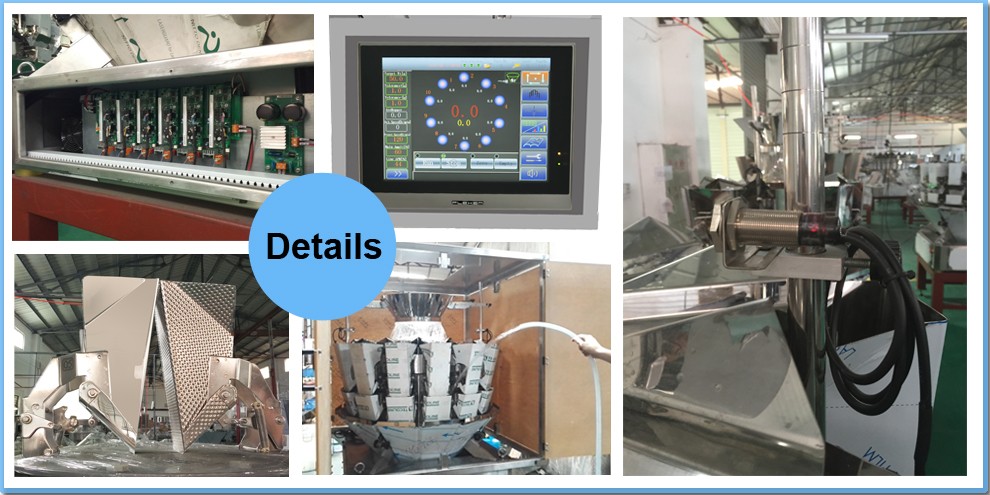

Multihead Weigher

IP65 waterproof

PC monitor production data

Modular driving system stable & convenient for service

4 base frame keep machine running stable & high precision

Hopper material : dimple( sticky product) and plain option( free flowing product)

Electronic boards exchangeable between different model

Load cell or photo sensor checking are available for different products

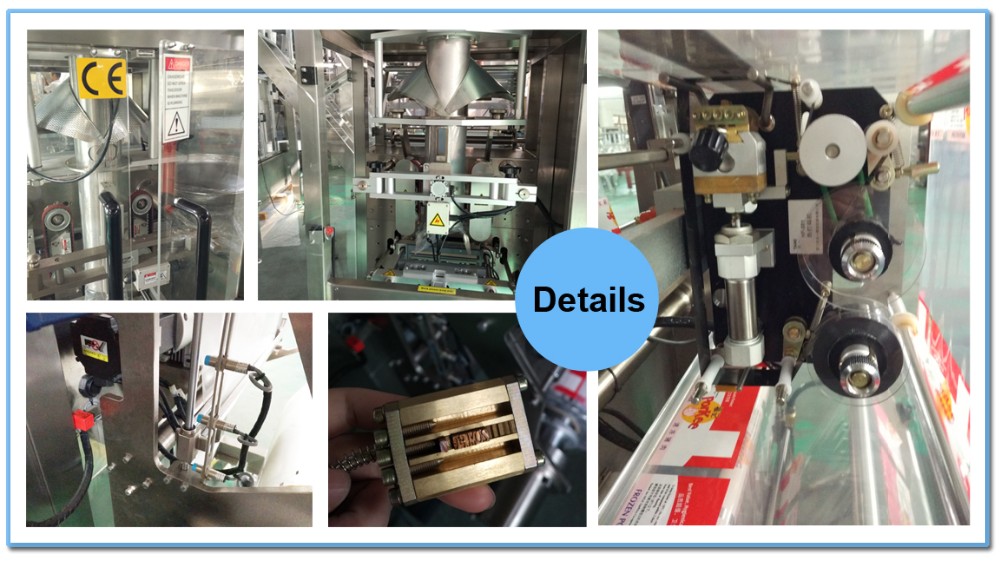

Vertical Dried Fruit Packaging Machine

* Complete control by branded PLC, stable high speed performance, reduce downtime

* Film auto centering while running

* Air lock film easy for loading new film

* Free production and EXP date printer

* Customize function & design can be offered

* Strong frame ensure running stable every day

* Lock door alarm and stop running ensure safety operation

There are customers prefer another type dried fruit packaging machine, this complete fruit packaging equipment solution handles stand up pouches, zipper pouches, doypack and other premade pouches. The advantages of dry fruits and nuts rotary packaging machine are:

1. Fully-automatically procedures from material feeding, weighing, filling and bag-making, date-printing to finished products output.

2. Fit for different bag size and bag width, adjustable on touch screen, easy and quick changeover for operator.

3. Different weight only need to preset on touch screen of multihead weigher.

Turnkey Solutions Experience

Exhibition

1. How can you meet our requirements and needs well?

We will recommend the suitable model of machine and make the unique design based on your project details and requirements.

2. Are you manufacturer or trading company?

We are manufacturer; we are specializing in packing machine line for many years.

3. How can we check your machine quality after we place an order?

We will send the photos and videos of the machine to you to check their running situation before delivery. What’s more, welcome to come to our factory to check the machine by your own

4. Why we should choose you?

² Professional team 24 hours provide service for you

² 15 months warranty

² Old machine parts can be replaced no matter how long you have bought our machine

² Oversea service is provided.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine