Automatic Ready Meal Packaging Machine With Gas Flush Modified Atmosphere Machine And Vacuum Tray Sealing Machine

Looking for an efficient solution to streamline your ready meal packaging process? A ground-breaking packing option for prepared meals is provided by Smart Weigh, which makes the weighing and filling of prepared meals automatic as well! Although every food product, packaging and process has different requirements and specifications, we will find professional ready meal packaging machine solution for your product. Through cooperation, Smart Weigh meal packaging machine will surely meet your requirements.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

The auto sealing and packing process is the main emphasis of the ready meal packaging machine on the market. As a ready to eat food packaging machine manufacturer, Smart Weigh offers comprehensive solutions for feeding, weighing, filling, packing, and sealing. We design and project manage the installation of entire ready meal packing machine lines, delivering automated full-line solutions that are flexible enough to meet your business needs and respond to changing markets.

| Name | Automatic Ready To Eat Food Packaging Machine |

| Capacity | 1000-1500 Trays/Hour |

| Filling volume | 50-500ML |

| Size | 2600mm×1000mm×1800mm / Customized |

| Weight | 600KG / Customized |

| Power | 5KW / Customized |

| Control | PLC |

| Sealing Type | Al-foil film / roll film |

| Air Consumption | 0.6 m3/min |

| The meal packaging machine can be Customized according to your Requirements. | |

※ Features

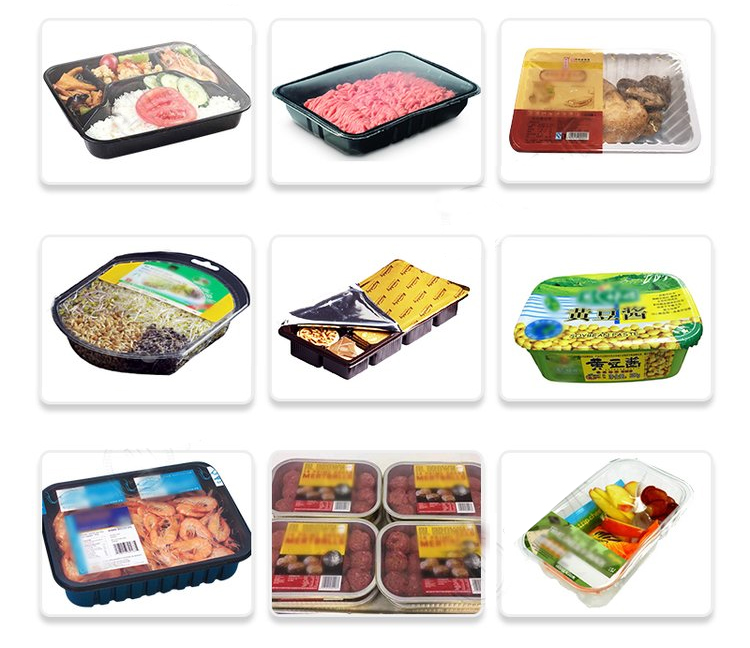

The ready meal packaging machine can be customized for all kinds of fastfood cook meals in tray, vegetable tray, sandwich tray, tofu tray and other container related food packing. It can automatic cup dropping(according to tray), filling(optional), roll film sealing, two side sealing, straight cutting, cup exiting. The ready to eat food packaging machine use Japan Omron programmable logic controller, CIP auto matic Cleaning Barrel, Taiwan pneumatic control components, Intelligent Digital Display Temperature Control System, seaing with high strength, good sealing, and low failure rate.

.

※ Ready Meal Packing Machine Solutions Detail

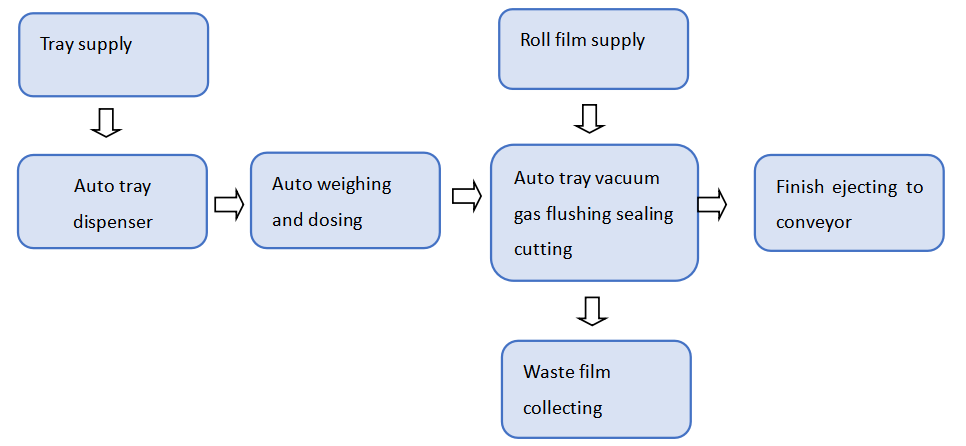

Fully automatic linear tray filling sealing machine can auto loading the empty trays, empty trays detecting, auto quantitative filling product into tray, automatic film pulling and waste collecting, auto tray vacuum gas flushing, sealing and film cutting,auto ejecting the finish product to conveyor. Its capacity 1000-1500trays per hour, suitable for the foods factory production needs. Less time and less labour for the same capacity. These systems are specifically designed to be integrated into automated production lines and can continuously form, fill, seal and label a variety of prepared food products. From frozen dinners and instant noodles to snack packs, ready-to-eat machines accommodate different food packaging styles such as plastic films, trays and boxes.

In order to meet the diverse packaging needs of the ready to eat meal packaging industry, Smart Weigh has various types of packaging machines to choose from. These machines are designed to handle different packaging formats, materials and production requirements. Some common types of meal packing machine include: gas flush modified atmosphere machine, vacuum tray sealing machine, and thermoforming packaging machines etc.

Vacuum gas flushing sealing cutting device

Vacuum gas flushing sealing cutting device

Tray dispenser

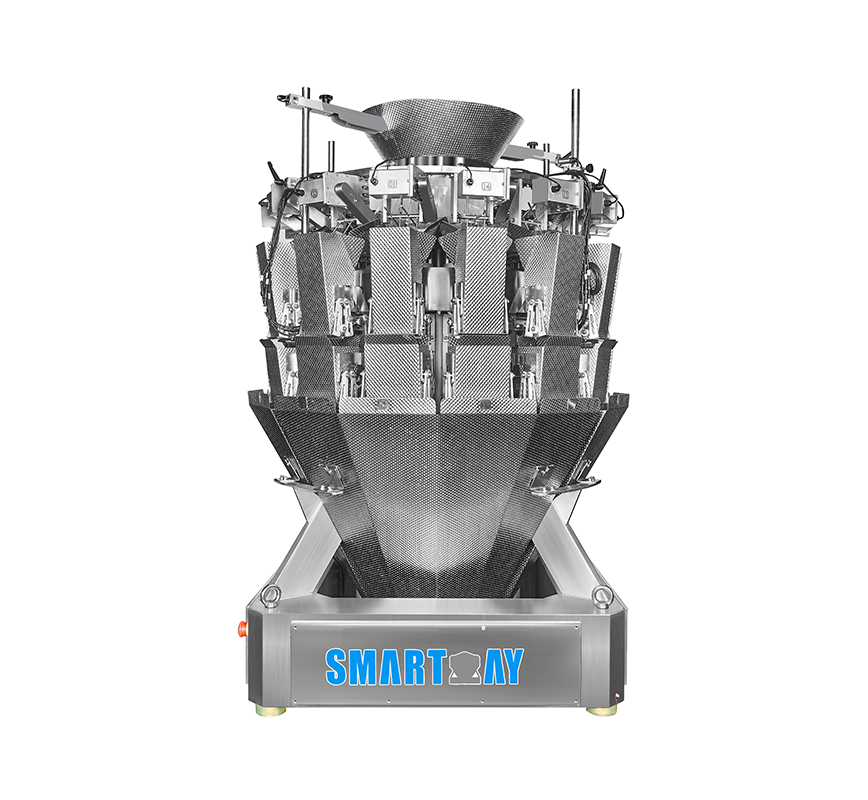

Multihead Weigher Ready Meal Packing Machine

※ Cooked Meal Packing Machine Flow Chart

Samples:

It is widely applicable to trays of various sizes and shapes. The following is part of the packaging effect show

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine