Automatic Snack Foods Packing Machine Made Of Stainless Steel 304

Smart Weigh chips packing machine is an advanced packaging solution designed specifically for the efficient and precise handling of chips and snack food products. Combining cutting-edge technology with user-friendly operation, this machine streamlines the packaging process from weighing and filling to sealing and labeling, ensuring product integrity, optimal shelf appeal, and adherence to industry standards. Automatic snack foods packaging machine for potato chips, banana chips, popcorn, tortilla, and other snack. Automatic process from product feeding, weighing, filling and packing.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

More Choices

Vertical packaging machine with multihead weigher is one of common snack packing machine solutions, it can weigh and pack a variety snack foods efficiently, including potato chips, banan chips, nuts, tortilla, prawn chips, stick snack, popcorn and others.

Smart Weigh chips packaging machine enabling rapid and accurate measurement of product weight. With its dual discharge capability, it ensures continuous and swift filling, minimizing product giveaway and maximizing production throughput. The scale's calibration and adjustment features allow for seamless adaptation to various chip sizes, shapes, and target weights, ensuring consistency in package contents across batches.Flexible packaging formats the snack food packaging machine offers compatibility with a wide range of packaging formats, catering to diverse market demands and branding requirements.

It seamlessly handles pre-made pouches such as gusset bags, mini doypacks, and stand-up zippered pouches, providing a professional, modern look that appeals to consumers. The machine's adaptability extends to different pouch sizes and materials, including barrier films for enhanced product freshness and shelf life.Efficient filling & sealing equipped with state-of-the-art filling mechanisms, the machine gently and accurately deposits snack food into pouches without causing damage or breakage.

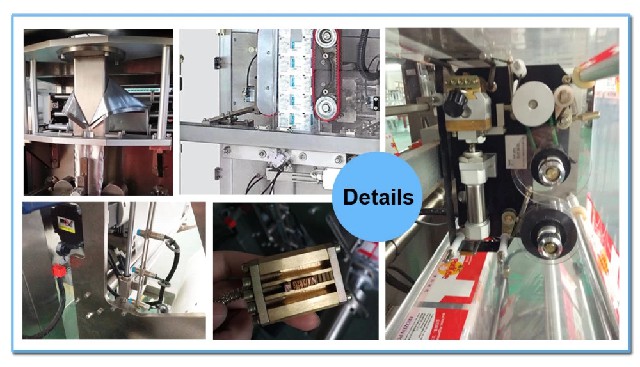

The chips packet machine can handle various sealing techniques, such as heat-sealing for plastic films or ultrasonic sealing for more delicate materials, guaranteeing secure closures that meet stringent quality and safety standards.Integrated printing & inspection incorporating an in-line printing module, the Smart Weigh potato chip bagging machine with multihead machine enables real-time printing of critical information onto the packaging, including batch codes, expiration dates, nutritional facts, and barcodes.

Additionally, the potato chips packing machine may incorporate advanced vision systems for automated inspection, verifying correct fill levels, seal integrity, and label placement before products leave the line, thereby reducing the risk of product recalls and enhancing overall quality control. User-friendly operation & maintenance designed with operator convenience in mind, the snack packaging machine with VFFS machine boasts an intuitive touchscreen interface that simplifies setup, monitoring, and data management. It provides real-time production statistics, alarm notifications, and diagnostic tools to facilitate proactive maintenance and minimize downtime.

Products Description

Model | SW-PL1 | ||||||

System | Multihead weigher vertical packing system | ||||||

Application | Granular product | ||||||

Weigh range | 10-1000g (10 head); 10-2000g (14 head) | ||||||

Accuracy | ±0.1-1.5 g | ||||||

Speed | 30-50 bags/min (normal) 50-70 bags/min (twin servo) 70-120 bags/min (continuous sealing) | ||||||

Bag size | Width=50-500mm, length=80-800mm(Depends on packing machine model) | ||||||

Bag style | Pillow bag, gusset bag, quad-sealed bag | ||||||

Bag material | Laminated or PE film | ||||||

Weighing method | Load cell | ||||||

Control penal | 7” or 10” touch screen | ||||||

Power supply | 5.95 KW | ||||||

Air consumption | 1.5m3/min | ||||||

Voltage | 220V/50HZ or 60HZ, single phase | ||||||

Packing size | 20” or 40” container | ||||||

Application

Multihead Weigher

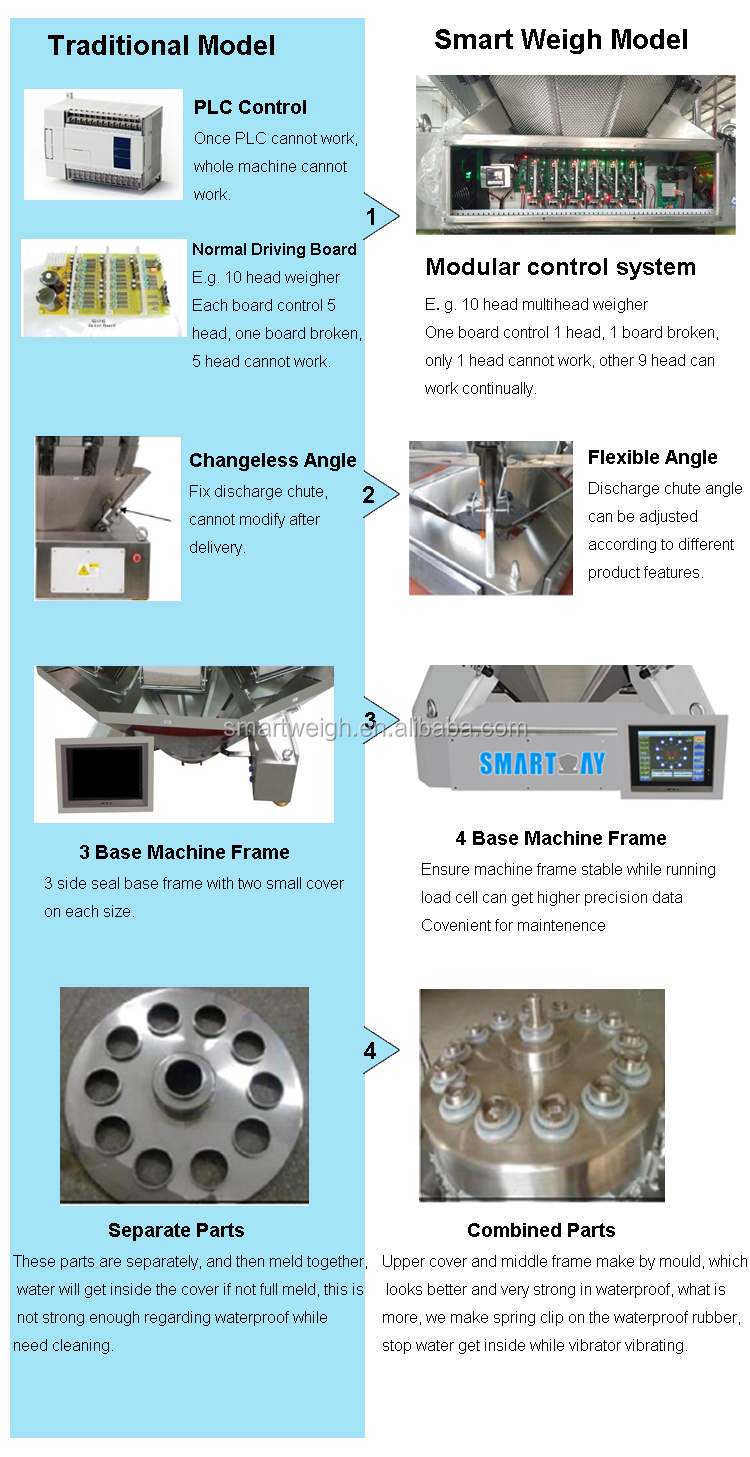

* Modular control system, more stability and lower maintenance fees;

* Production records can be checked at any time or download to PC;

* Load cell or photo sensor checking to satisfy different requirements;

* Preset stagger dump function to stop blockage;

* Design linear feeder pan deeply to stop small granule products leaking out;

* Refer to product features, select automatic or manual adjust feeding amplitude;

* Food contact parts disassembling without tools, which is easier to clean;

* Multi-languages touch screen for various clients, English, French, Spanish, etc;

* PC monitor production status, clear on production progress (Option).

Vertical Packing Machine

finished in one operation;

* Separate circuit boxes for pneumatic and power control. Low noise, and more stable;

* Film-pulling with servo motor for precision, pulling belt with cover to protect moisture;

* Open door alarm and stop machine running in any condition for safety regulation;

* Film centering automatically is available (Optional);

* Only control touch screen to adjust bag deviation. Simple operation;

* Film in roller can be locked and unlocked by air, convenient while change film

Packing&Shipping

Payment: TT, 50% deposit, 50% before shipment; L/C;

based on your project details and requirements.

warranty Old machine parts can be replaced no matter how long you have bought our machine

* Oversea sevice is provided.

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Quick Link

Packing Machine