easy-operating electronic weighing machine or inquire now for food labeling

1. Smart Weigh pack electronic weighing machine is manufactured adopting advanced machines. These machines mainly include punching machine, bending machine, stamping machine, milling machine, cutting machine, etc. An increased efficiency can be seen on the smart Weigh packing machine

2. Guangdong Smart Weigh Packaging Machinery Co., Ltd is dedicated to making continuous customer service improvement a priority. Smart Weigh sealing machine offer some of the lowest noise available in the industry

3. electronic weighing machine is widely used in the field increasingly because of its unique advantages such as and so on. Smart Weigh packing machine features precision and functional reliability

Model | SW-ML14 |

Weighing Range | 20-8000 grams |

Max. Speed | 90 bags/min |

Accuracy | + 0.2-2.0 grams |

Weigh Bucket | 5.0L |

Control Penal | 9.7" Touch Screen |

Power Supply | 220V/50HZ or 60HZ; 12A; 1500W |

Driving System | Stepper Motor |

Packing Dimension | 2150L*1400W*1800H mm |

Gross Weight | 800 kg |

※ Features

◇ IP65 waterproof, use water cleaning directly, save time while cleaning;

◆ Four side seal base frame ensure stable while running, big cover easy for maintenance;

◇ Modular control system, more stability and lower maintenance fees;

◆ Rotary or vibrating top cone can be selected;

◇ Load cell or photo sensor checking to satisfy different requirements;

◆ Preset stagger dump function to stop blockage;

◇ 9.7' touch screen with user friendly menu, easy to change in different menu;

◆ Checking signal connection with another equipment on the screen directly;

◇ Food contact parts disassembling without tools, which is easier to clean;

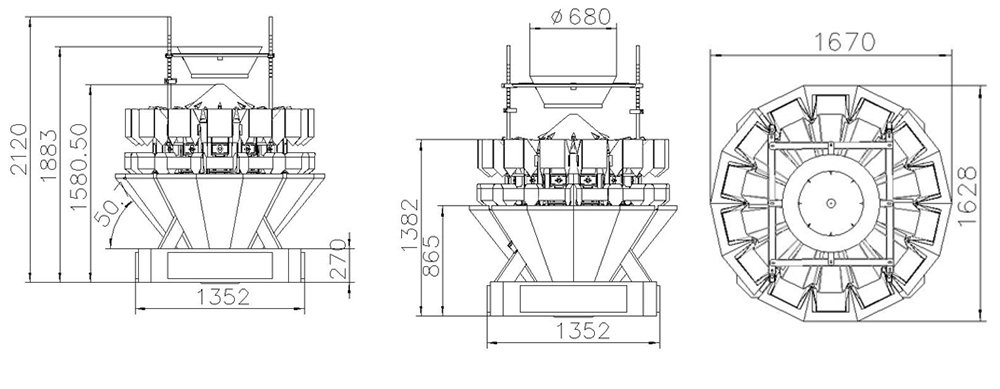

※ Dimensions

※ Application

It is mainly apply in automatic weighing various granular products in food or non-food industries, such as potato chips, nuts, frozen food, vegetable, sea food, nail, etc.

※ Function

※ Product Certificate

Company Features

1. Guangdong Smart Weigh Packaging Machinery Co., Ltd is an ambitious and fast-growing manufacturing company. We specialize in the design and production of . Our factory features a reasonable layout. From the delivery of raw materials to final despatch, our highly efficient route throughout the factory means everything is clear and defined.

2. The factory has a Target Operating Model System (TOMS) which helps the factory define what specific resources and capabilities it needs. This will help realize the company's defined vision, goals, and objectives for its customers.

3. Perfect quality control system 100% guarantees the quality of . Hopefully, our will be successful in reaching out to the world. Please contact.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425