Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost. Contact us Now!

Customize design weigh or count sticky gummy candy into bags and pouches with over 10 years experience.

SEND INQUIRY NOW

Smart Weigh specializes in providing two distinct types of gummy packaging machines, each designed to cater to different packaging needs.

The first type is specifically engineered for creating pillow bags, a popular choice for their compact and convenient design, which is ideal for a variety of gummy products. This machine is adept at efficiently packing gummies into these pillow bags, ensuring a consistent and reliable packaging process.

The second type of machine offered by Smart Weigh is designed for filling premade pouches. This machine is particularly suitable for businesses that prefer using pouches that are already shaped and require filling and sealing. The premade pouch packing machine is versatile and can handle a range of pouch sizes and styles, making it a flexible solution for different packaging requirements.

Both types of gummy packing machines from Smart Weigh are built with advanced technology, ensuring precision, speed, and reliability in the packaging process. They are designed to meet the varying needs of the confectionery industry, providing efficient and effective solutions for gummy packaging. Whether it's the compact pillow bags or the versatile premade pouches, Smart Weigh's machinery is equipped to deliver high-quality packaging performance.

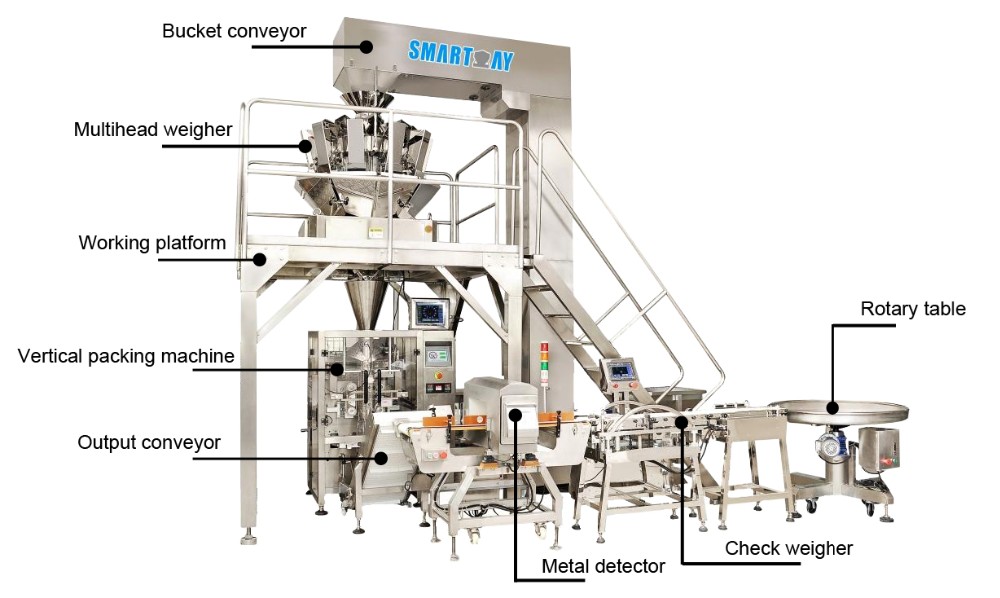

◆ Gummy Packaging Machine can realize full automation of material conveying, weighing and measuring, coding, filling, bag forming and cutting, sealing and output for hard or soft candy;

◇ Multihead weigher modular control system keep production efficiency;

◆ High weighing precision by load cell weighing;

◇ Open door alarm and stop machine running in any condition for safety regulation;

◆ Vertical gummy packaging machine can make bags quickly, and is suitable for pillow bag and pillow bag with gusset.

◇ All parts can be taken out without tools.

Weighing Range | 10-2000 grams |

Bag Style | Pillow bag, gusset bag, four side seal bag |

Bag Size | Length: 120-400mm Width: 120-350 mm |

Bag Material | Laminated film, Mono PE film |

Film Thickness | 0.04-0.09 mm |

Max. Speed | 20-80 bags/min |

Accuracy | ±0.1-1.5 grams |

Weigh Bucket | 1.6L or 2.5 L |

Control Penal | 7" or 9.7 " Touch Screen |

Air Consumption | 0.8 Mps, 0.4m3/min |

Driving System | Step motor for scale, servo motor for packing machine |

Power Supply | 220V/50 Hz or 60 Hz, 18A, 3500 W |

1. Weighing Equipment: 10/14/20 heads multihead weigher.

2. Infeed Bucket Conveyor: Z-type infeed bucket conveyor, big bucket elevator, inclined conveyor.

3.Working Platform: 304SS or mild steel frame. (Color can be customized)

4. Packing machine: Vertical packing machine.

5.Take off Conveyor: 304SS frame with belt or chain plate.

◆ Premade Pouch Gummy Packing Machine can realize full automation of material conveying, weighing, empty pouches picking up, date printing, pouch opening, pouch filling, sealing and output;

◇ Multihead weigher modular control system keep production efficiency;

◆ High weighing precision by load cell weighing;

◇ Open door alarm and stop machine running in any condition for safety regulation;

◆ Pouch sizes are adjustable on touch screen, easy operation.

Smart Weight provides you with an ideal weighing and packaging solution to pack gummy products. Besides, our weighing machine can weigh particles, powders, pickle food, meat and etc. The specially designed weighing machine can solve the weighing challenges. For example, the multi head weigher with dimple plate or Teflon coating is suitable for viscous and oily materials, the 24 head multi head weigher is suitable for mixture flavor snacks, and the 16 head stick shape multi head weigher can solve the weighing of stick shape materials and bags in bags products. Our packaging machine adopts different sealing methods and is suitable for different bag types. For example, vertical packaging machine is applicable to pillow bags, gusset bags, four side seal bags, etc., and the premade bag packaging machine is applicable to zipper bags, stand up pouches, doypack bags, flat bags, etc. Smart Weigh can also plan the weighing and packaging system solution for you according to the actual production situation of customers, so as to achieve the effect of high precision weighing, high efficiency packing and space saving.

How does the customer check the quality of the machine?

Before delivery, Smart Weight will send you photos and videos of the machine. More importantly, we welcome customers to check the operation of the machine on site.

How does Smart Weight meet customer requirements and demands?

We provide customized services for you, and answer customers' questions online 24 hours at the same time.

What is the payment method?

Direct telegraphic transfer through bank account

L/C at sight.

CONTACT US

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Get Free Quotation Now!

Copyright © Guangdong Smartweigh Packaging Machinery Co., Ltd. | All Rights Reserved