How to Choose a Multihead Weigher Manufacturer: Making the Right Decision?

Navigating the world of multihead weighing machines manufacturers can be a daunting task. If you are a packing machine manufacturer, food manufacturer, or a food packaging agency in food industry, you need a partner who understands your needs and can provide efficient solutions. As a seasoned multihead combination weigher factory from China, with over a decade of experience, we're here to guide you through this process.

When choosing a multihead weigher manufacturer, it's essential to consider the range of product offerings, customization capabilities, and the provision of end-to-end solutions. At Smart Weigh, we excel in all these areas, ensuring our clients receive top-notch service and products.

What should you look for in multi head weigher manufacturer?

Firstly, consider the breadth of product offerings. A manufacturer should be able to provide a variety of multihead weighers to cater to different needs. At Smart Weigh, we manufacture standard multihead weighers suitable for a range of products, including snacks and chips. But that's not all.

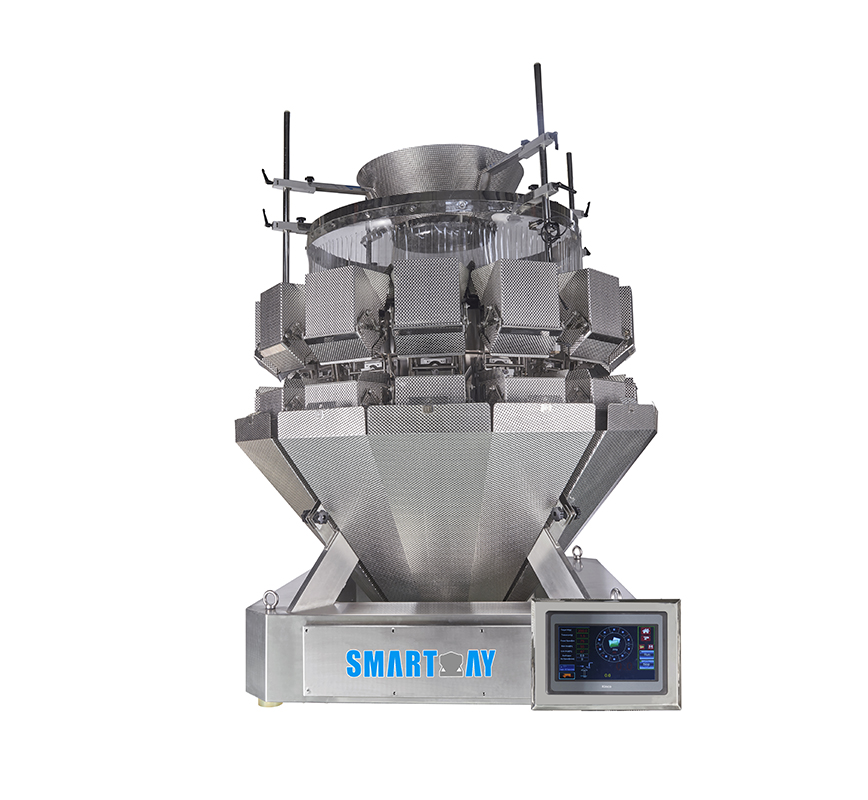

Standard 10 head multihead weigher

Standard 10 head multihead weigher Mini 14 head weigher

Mini 14 head weigher

Trail mix multihead weigher

Trail mix multihead weigherCan the manufacturer customize the weighers to suit your specific needs?

At Smart Weigh, we not only offer standard, high speed and mixture multihead weighing machines for snacks, chips, frozen food, candy, nuts, dry fruits, cereals, oats, vegetables, and other products; but also support Original Design Manufacturing (ODM) services, enabling us to tailor our weighers specifically for various products such as meat, ready meals, kimchi, screws and hardware. This adaptability ensures our clients find solutions that perfectly fit their unique needs.

Does the manufacturer provide comprehensive solutions that cover the entire production process?

At Smart Weigh, we offer automation integrated weighing packaging machinery solutions that encompass everything from feeding and weighing to filling, packing, double weight checking, metal inspecting, cartoning, and even palletizing. This end-to-end service ensures seamless integration and efficiency for our clients' operations.

Multihead Weigher Vertical Form Fill Seal Machine Line

Multihead Weigher Vertical Form Fill Seal Machine Line

Multihead Weigher Jar Packaging Machine Line

Multihead Weigher Jar Packaging Machine Line Multihead Combination Weigher Tray Denesting Line

Multihead Combination Weigher Tray Denesting LineIf you need multi head weigher only, no worries the its connection with your existing packing equipment. Just share us your current machines' signal mode, we will use the right connection.

What does this mean for you as a packing machine manufacturer, a food manufacturer, or a food packaging agency?

Choosing Smart Weigh as your multihead weigher manufacturer means partnering with a company that understands your needs, provides customized solutions, and helps streamline your operations. We are now having multihead weigher vertical packaging machine, It signifies a commitment to your success. But don't just take my word for it. Check out some of our customer testimonials to see how we've helped businesses like yours thrive.

Case 1:

One of our clients, a renowned snack food manufacturer, was struggling with updating their existing weighing and packing system. Old weighing packing machines were inefficient and often resulted in inaccurate portioning. After switching to our customized twin 10 head multihead weigher with vertical form fill seal machine, they saw a significant improvement in their production process with lower cost. The weigher was able to accurately portion their product, reducing waste and increasing efficiency. This is just one example of how our tailored solutions can make a difference.

Case 2:

Another client, a packing machine manufacturer in overseas, was looking for flexibile multihead weighing machines to work with their packaging machines. They needed a stable weighing machine that could handle most of food in the current market, and we exported them some standard models for snacks, candy, cereals & oats, vegetables & salad. It provided a seamless, efficient process that significantly improved their operations.

Ready to take the next step?

If you're prepared to elevate your packaging process operations and ready to collaborate with a partner who can equip you with the necessary tools and expertise to excel, we would be delighted to start a conversation. We are confident that our collaboration can yield exceptional results.

In conclusion, selecting a multihead weigher manufacturer is a significant decision that can greatly impact your business operations. At Smart Weigh, we are ready to be the partner that helps drive your success. Let's work together to outperform the competition.

Frequently Asked Questions

1. What is a multihead weigher?

A multihead weigher is a type of computer weighing machine that is commonly used in the food packaging industry. It uses multiple weigh heads to accurately measure out portions of a product.

2. What is the difference between multihead weigher and linear weigher?

The biggest difference is their working principle.

Multihead weighers work on the principle of combination weighing. The process begins by distributing the product to be weighed across the multiple weigh hoppers or heads of the machine. The weigher's computer then analyzes the weights of all the portions and identifies the combination of hoppers that gets closest to the desired target weight. The selected hoppers then open simultaneously, and the weighed product is dispensed into the package.

Linear weighers do not have the combination process. The product to be weighed is fed into the top of the weigher, where it is separated and moved along multiple linear paths (feeding lanes). Vibrations along these lanes control the flow of product into the weigh buckets. Once a weigh bucket fills to a pre-defined weight, the vibration pans stop, and then buckets open and discharged into the package.

3. What is Original Design Manufacturing (ODM)?

Original Design Manufacturing, or ODM, is a type of manufacturing where the manufacturer designs and builds a product as per the customer's specifications. At Smart Weigh, we offer ODM services, allowing us to create multihead weighers that are specifically tailored to your products.

4. How can I get in touch with Smart Weigh for more information?

We would be delighted to answer any further questions you may have. You can reach us through our at export@smartweighpack.com or send inquries on the contact page.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine