Know about the Multihead Weigher Working Principles | Smart Weigh

Multihead weighers have become indispensable in modern production lines across various industries. These advanced machines play a crucial role in accurately measuring and distributing products for packaging. In this article, we will delve into the intricacies of multihead weighers, exploring their components, working principle, benefits, considerations, and frequently asked questions. Let's uncover the inner workings of this technology and understand how it revolutionizes the weighing and packaging process.

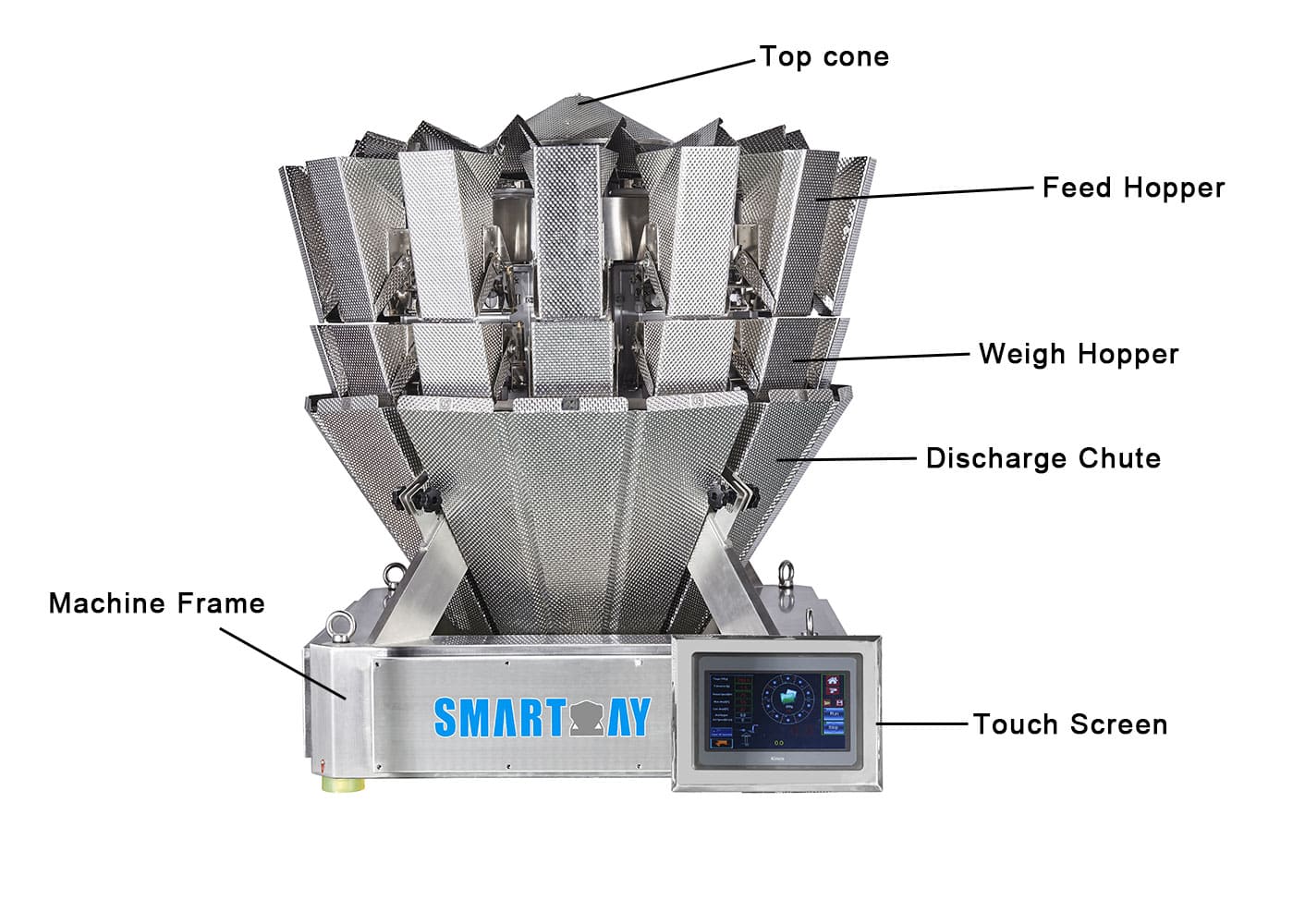

What are the Basic Components of a Multihead Weighing Machine?

To comprehend how a multi head weigher functions, we need to familiarize ourselves with its key components. The main body and frame provide stability and support for the machine, while the hopper system acts as a reservoir for the product. Vibratory feeders ensure smooth and consistent product flow, while weighing buckets or heads accurately measure the desired quantity. Lastly, the control panel and software facilitate operation and data processing.

What is the Working Principle of Multihead Weighers?

Step 1: Product Distribution

In this phase, the multihead weigher efficiently distributes the product to each weighing bucket. Vibratory feeders play a crucial role here, ensuring a consistent and controlled flow of the product. Optimization techniques are employed to enhance the distribution process, achieving optimal speed and accuracy.

Step 2: Product Weighing

Once the product is evenly distributed, the weigh hoppers come into action. Load cells, integrated within each bucket, measure the weight of the product accurately. Precise measurements are crucial to ensure the desired quantity in each package. The multihead weigher utilizes various strategies to achieve exceptional weighing accuracy.

Step 3: Data Processing and Calculations

The control panel and software are the brain behind the multihead weigher's operation. They process the data from the load cells and perform calculations to determine the optimal combination of hoppers that will fulfill the target weight requirement. Real-time adjustments and feedback loops further enhance the accuracy and efficiency of the weighing process.

Step 4: Product Discharge and Packaging

Once the correct combination of buckets is determined, the product is discharged into the packaging machine. Different discharge mechanisms are utilized depending on the product and packaging requirements. Integration with packaging machines ensures a seamless transition, resulting in consistent and reliable packaging outcomes.

What are Benefits and Advantages of Using a Multihead Scale?

The adoption of multihead weighing packaging machine brings numerous benefits to production systems:

1. Increased Efficiency and Productivity: Multi head weighers can handle high-speed weighing and packaging, significantly improving production efficiency.

2. Enhanced Accuracy and Consistency: With high accuracy weighing and filling, multihead weighers deliver consistent package weights, minimizing product giveaway.

3. Flexibility in Handling Various Product Types: Multihead weighers are adaptable and can handle a wide range of industry, including snack, dry, sticky, fragile, and granular food or non-food.

4. Reduction in Labor Costs: Automated operation reduces the need for manual labor, leading to cost savings and increased productivity.

5. Minimization of Product Waste and Giveaway: Accurate measurements minimize product waste, resulting in cost savings and improved profitability.

What are the Factors to Consider When Choosing a Multihead Weigher solutions?

When selecting a multihead weigher for your specific needs, several factors should be considered:

1. Production Requirements and Capacity: Evaluate the required throughput and capacity to ensure the chosen multihead weigher can handle the desired production levels.

2. Product Characteristics and Packaging Needs: Consider the size, shape, and properties of your products, as well as the desired packaging formats.

3. Machine Customization Options: Determine if the multihead weigher can be customized to meet your unique requirements and integrate seamlessly into your existing production line.

4. Hygiene and Cleaning Considerations: For industries with strict hygiene standards, choose a multihead weigher with easy-to-clean components and sanitary designs.

5. Maintenance and After-Sales Support: Assess the availability of spare parts, technical support, and maintenance services to ensure uninterrupted operation and longevity of the machine.

Conclusion

Multihead weighers have transformed the weighing and packaging process in numerous industries, offering increased efficiency, accuracy, and flexibility. Understanding the components and working principle of a multihead weigher provides valuable insights into its capabilities. By considering factors such as production requirements, product characteristics, and maintenance needs, you can choose the right multihead weigher for your specific application. Embracing this advanced technology empowers businesses to optimize their production processes, minimize waste, and deliver consistent, high-quality products to consumers.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine