Manufacturers of Vertical Form Fill Seal (VFFS) Machines in China

The global demand for efficient and reliable packaging solutions is ever-increasing. For factory managers and production teams, especially in the food industry, selecting the right Vertical Form Fill Seal (VFFS) machine is a critical decision impacting throughput, product integrity, and overall operational costs. Chinese manufacturers have become formidable players in this arena, offering technologically advanced machinery that provides a strong return on investment. This article delves into some of the leading VFFS machine manufacturers in China, helping you identify partners who can meet your specific packaging challenges.

Manufacturers of Vertical Form Fill Seal (VFFS) Machines in China

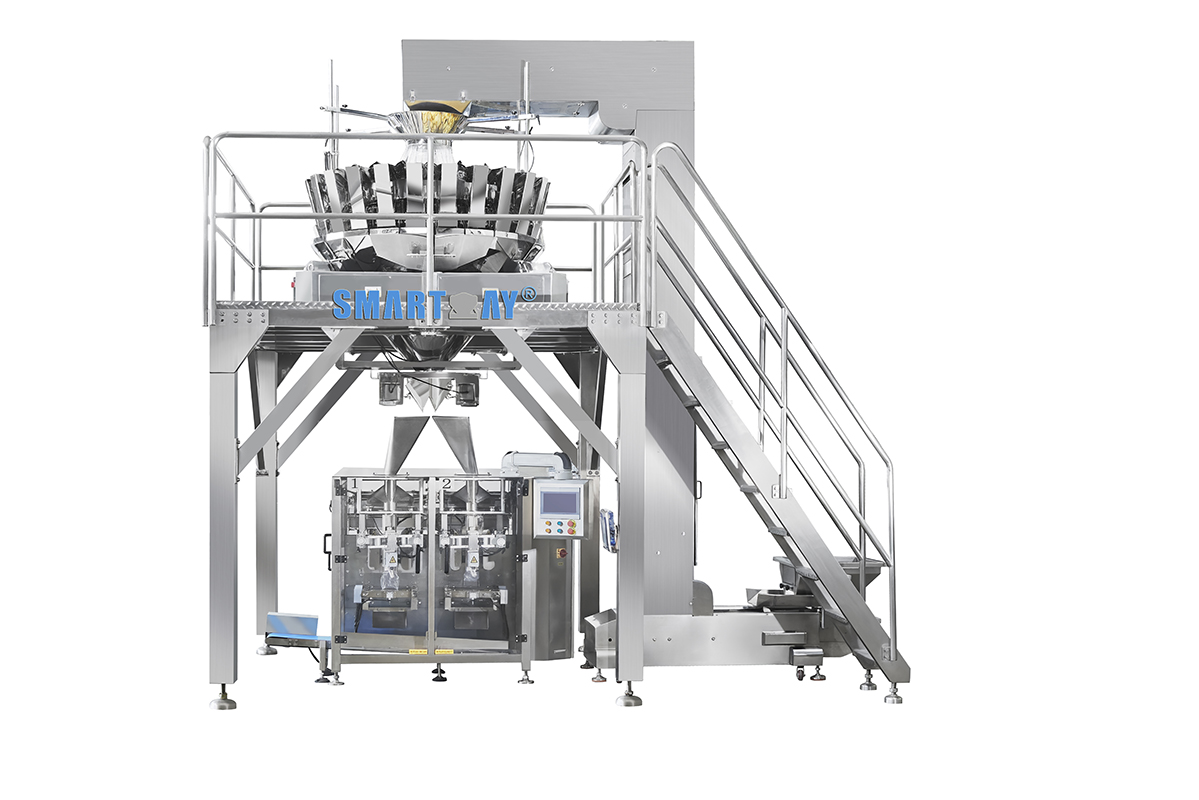

1. Guangdong Smart Weigh Packaging Machinery

Core Competencies & Standout Features:

Smart Weigh excels in providing fully integrated and customized packaging lines, not just standalone machines. Their strength lies in combining high-precision multihead weighers seamlessly with robust VFFS systems and intelligent downstream equipment like checkweighers, metal detectors, and carton packing solutions. This holistic approach ensures optimal line efficiency and minimal product giveaway.

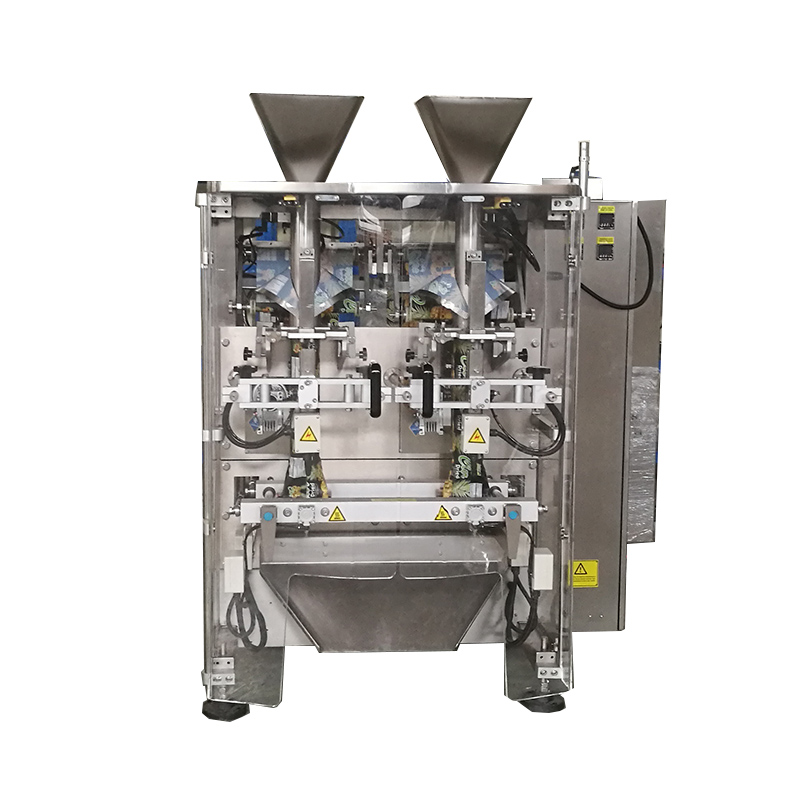

Dual VFFS Model & Performance:

Their standout VFFS solution is the SW-DP420 Dual Vertical Form Fill Seal Machine. This innovative system features two independent VFFS units operating in parallel, fed by a central multihead weigher.

Speed: Each side of the dual system can achieve 65-75 bags per minute, leading to a combined total output of 130-150 bags per minute. This significantly boosts throughput for high-volume production.

Accuracy: When paired with Smart Weigh's multihead weighers, the system maintains exceptional weighing accuracy, often within ±0.1g to ±0.5g depending on the product. This precision can reduce product giveaway by up to 40% compared to less sophisticated weighing methods, translating directly to raw material savings.

Versatility: The SW-DP420 can handle various bag types (pillow, gusseted, quad seal) and film materials.

Industry Applications & Benefits for Manufacturers:

Smart Weigh's solutions are particularly well-suited for:

Snack Foods: (chips, pretzels, nuts) where high speed and accuracy are paramount.

Frozen Foods: (vegetables, dumplings, seafood) requiring durable sealing for cold-chain integrity.

Granular Products: (coffee beans, rice, sugar, pet food) where precise weighing minimizes waste.

Powders: (flour, spices, milk powder) with options for auger fillers for accurate dosing.

Smart Weigh's commitment extends beyond machine supply. They offer comprehensive project consultation, installation, training, and responsive after-sales support. Their user-friendly HMI interfaces, often multi-lingual, simplify operation and reduce operator training time. Furthermore, their design philosophy focuses on easy cleaning and quick changeovers, minimizing downtime between product runs – a critical factor for manufacturers with diverse product portfolios.

2. Hangzhou Youngsun Intelligent Equipment Co., Ltd.

Core Competencies & Standout Features:

Youngsun is recognized for its broad range of packaging machinery, including VFFS systems that incorporate advanced servo-driven technology. This allows for precise control over film pulling and sealing, contributing to consistent bag quality and reduced energy consumption.

Key Technology & Performance:

Their VFFS machines often feature adaptive tension control for film handling, which optimizes film usage and can accommodate variations in packaging material properties. For liquid or semi-liquid products, some models offer ultrasonic sealing technology, ensuring highly reliable, leak-proof seals crucial for dairy, beverages, and sauces.

Industry Applications & Benefits for Manufacturers:

Youngsun has a strong presence in:

Liquid & Paste Packaging: (sauces, dairy, juices) where seal integrity is non-negotiable.

Pharmaceuticals & Chemicals: Requiring precision and often specialized material handling. Their patented quick-change forming collar systems can reduce format changeover times by up to 75% compared to older designs, a significant boost to production flexibility for manufacturers handling multiple SKUs.

Youngsun's focus on intelligent automation and system integration makes them a go-to for companies looking to upgrade their packaging lines with smart, efficient solutions.

3. Ruian Honetop Machinery Co., Ltd.

Core Competencies & Standout Features:

Honetop offers a wide array of VFFS machines known for their versatility in handling diverse product types – from fine powders and granules to irregularly shaped solid items. Their machines are built with robust construction, designed for durability in demanding production environments.

Key Technology & Performance:

They often incorporate reliable PLC control systems with intuitive touch-screen interfaces. Options for various dosing systems (volumetric cup, auger filler, multihead weigher) allow for tailored solutions depending on product characteristics.

Industry Applications & Benefits for Manufacturers:

Honetop machines are frequently found in:

Hardware & Small Parts: Where counting or volumetric filling is efficient.

Chemicals & Non-Food Powders: Offering cost-effective solutions for bulk packaging.

Basic Food Grains & Pulses: Providing reliable performance for staple goods.

Honetop provides dependable, workhorse VFFS machines that offer a good balance of performance and cost-effectiveness, particularly for small to medium-sized enterprises seeking straightforward and durable packaging solutions.

4. Shanghai Boevan Packaging Machinery Co., Ltd.

Core Competencies & Standout Features:

Boevan specializes in VFFS machines that often integrate advanced features like nitrogen flushing systems, critical for extending the shelf life of oxygen-sensitive products. Their engineering focuses on achieving high-quality seals and consistent package presentation.

Key Technology & Performance:

Their machines often utilize precise temperature control and sealing jaw designs to ensure hermetic seals, vital for modified atmosphere packaging (MAP). They also offer solutions compatible with various laminate films requiring specific sealing parameters.

Industry Applications & Benefits for Manufacturers:

Boevan is a strong contender for:

Coffee & Tea: Where aroma preservation and freshness are key.

Nuts & Dried Fruits: Prone to oxidation if not packaged correctly.

Pharmaceutical Powders & Granules: Requiring high barrier protection.

For manufacturers prioritizing product freshness and extended shelf life through controlled atmosphere packaging, Boevan offers specialized VFFS solutions with advanced sealing and gas flushing capabilities.

5. Foshan Jintian Packaging Machinery Co., Ltd.

Core Competencies & Standout Features:

Foshan Jintian Packaging Machinery has established itself as a provider of a comprehensive range of VFFS machines and auxiliary packaging equipment, catering to diverse industries. They are known for offering reliable and cost-effective solutions, often appealing to small and medium-sized enterprises (SMEs) as well as larger companies looking for straightforward, efficient packaging lines. Their portfolio typically includes machines for various bag types and sizes.

Industry Applications & Benefits for Manufacturers:

Foshan Jintian's VFFS machines are commonly employed in packaging:

Granular Products: Such as rice, sugar, salt, seeds, and coffee beans.

Powder Products: Including flour, milk powder, spices, and detergent powder.

Snack Foods & Small Hardware: Items like chips, candies, screws, and small plastic parts.

Liquids & Pastes: With appropriate piston or pump filler integration for products like sauces, oils, and creams.

Manufacturers benefit from Jintian's offerings through access to dependable packaging technology at a competitive price point, allowing for automation of packaging processes to improve efficiency and reduce labor costs. Their machines often emphasize ease of operation and maintenance.

Foshan Jintian provides a solid value proposition for businesses seeking functional, reliable VFFS packaging solutions without the premium cost associated with highly specialized or top-tier international brands. They offer a good balance of performance, affordability, and adaptability for a wide range of common packaging needs, making them a popular choice in both domestic and international markets.

6. Baopack Auto Packaging Machine Co., Ltd.

Core Competencies & Standout Features:

Baopack is known for its VFFS systems that demonstrate exceptional film handling capabilities, crucial for minimizing material waste, especially when working with thinner or more challenging film types. Their precision tension control systems are a key feature.

Key Technology & Performance:

Their machines often incorporate servo-driven film transport and robust sealing mechanisms that ensure consistent bag lengths and strong seals even at higher speeds. They offer solutions for a variety of bag styles, including quad seal bags.

Industry Applications & Benefits for Manufacturers:

Baopack systems are frequently chosen for:

Confectionery & Bakery Items: Where gentle handling and attractive packaging are important.

Powders & Granules: Requiring accurate dosing and reliable sealing.

Baopack's expertise in film handling and precise control translates into reduced film waste and consistently well-formed packages, contributing to better aesthetics and cost savings.

7. Foshan Land Packaging Machinery Co., Ltd.

Core Competencies & Standout Features:

Land Packaging designs its VFFS machines with a strong emphasis on sanitary construction and contamination prevention, making them suitable for industries with stringent hygiene requirements.

Key Technology & Performance:

Their machines often feature stainless steel construction, smooth surfaces, and easily accessible components to facilitate thorough cleaning. Options for dust extraction and control are also available for powder packaging.

Industry Applications & Benefits for Manufacturers:

Well-suited for:

Medical Supplies & Disposable Hygiene Products: Where cleanliness is paramount.

Food Products with High Sanitary Standards: Such as infant formula or specialized nutritional powders.

For industries where hygiene and ease of sanitation are top priorities, Land Packaging offers VFFS solutions designed to meet these rigorous standards.

8. Wenzhou Kingsun Machinery Industrial Co., Ltd.

Core Competencies & Standout Features:

Kingsun has carved a niche by developing specialized VFFS solutions for products that are traditionally difficult to handle, such as sticky, oily, or highly irregular items. They often customize feeding and dosing systems.

Key Technology & Performance:

Their expertise lies in integrating VFFS machines with specialized weighers or counters designed for challenging products. This might include vibration feeders or belt weighers adapted for specific product characteristics.

Industry Applications & Benefits for Manufacturers:

Notable success in:

Gummy Candies & Sticky Confectionery:

Hardware & Irregularly Shaped Industrial Parts:

Certain Frozen Foods or Oily Snacks:

Value Proposition: Kingsun is a problem-solver for manufacturers facing unique packaging challenges with difficult-to-handle products, offering customized systems where standard VFFS machines might struggle.

9. Shanghai Xingfeipack Co., Ltd.

Core Competencies & Standout Features:

Xingfeipack often integrates vision systems and advanced quality control mechanisms into their VFFS lines. This focus on in-line inspection helps reduce defect rates and ensure consistent package appearance.

Key Technology & Performance:

Their "smart" detection systems can identify issues like incorrect sealing, misaligned printing, or empty bags, automatically rejecting defective packages while maintaining line speeds, which can be up to 100 bags per minute on some models.

Industry Applications & Benefits for Manufacturers:

Particularly strong in:

Retail-Ready Consumer Goods: Where package appearance is critical for shelf appeal.

High-Value Products: Where minimizing defects and ensuring quality is essential.

Xingfeipack appeals to quality-conscious manufacturers who need to ensure every package meets stringent standards, reducing the risk of rejects and enhancing brand image.

10. Zhejiang Zhuxin Machinery Co., Ltd.

Core Competencies & Standout Features:

Zhuxin specializes in high-capacity, heavy-duty VFFS systems designed for industrial applications where large volumes and robust performance are critical. Their machines are built to withstand demanding production environments.

Key Technology & Performance:

They focus on reinforced frame designs, durable components, and powerful drive systems to handle larger bag sizes and heavier product weights reliably. Their systems are often engineered for continuous, high-throughput operation.

Industry Applications & Benefits for Manufacturers:

Strong presence in:

Bulk Material Packaging: (construction aggregates, industrial chemicals, agricultural fertilizers).

Large-Format Pet Food & Animal Feed:

Industrial Powders & Granules:

Value Proposition: For manufacturers needing to package large volumes of bulk materials in demanding industrial settings, Zhuxin offers robust, high-capacity VFFS solutions built for endurance and high throughput.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Quick Link

Packing Machine