Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing

The material of Guangdong Smart Weigh Packaging Machinery Co., Ltd will not take any bad effect on people during use. An increased efficiency can be seen on the smart Weigh packing machine

brand

smartweigh

country of origin

china

material

sus304

certificate

ce

loading port

zhongshan port, china

moq

1

payment

tt, lc

Company Advantages

1. The material of Guangdong Smart Weigh Packaging Machinery Co., Ltd will not take any bad effect on people during use. An increased efficiency can be seen on the smart Weigh packing machine

2. Works can get rid of jobs that are dirty dull. They will take more interest in their work and their efficiency will increase. Auto-adjustable guides of Smart Weigh packaging machine ensure precise loading position

3. The product is offered after testing against various quality measures. Smart Weigh vacuum packaging machine is set to dominate the market

4. Advanced testing equipment and perfect quality assurance system ensure the automated packaging systems ltd 's high performance. Smart Weigh pouch is a great packaging for grinned coffee, flour, spices, salt or instant drink mixes

5. The product performance has been greatly improved by our innovative R&D team. Smart Weigh's uniquely designed packing machines are simple to use and are cost effective

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 6]()

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 7]()

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 8]()

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 9]()

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 10]()

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 11]()

![Smartweigh Pack best-selling automated packaging systems ltd factory for food weighing 12]()

Company Features

1. Smartweigh Packing Machine is a professional high-tech enterprise, specialized in manufacturing automated packaging systems ltd . We have a top R&D team to keep improving quality and design for our automatic packing system .

2. The cutting-edge technology adopted in advanced packaging systems helps us win more and more customers.

3. We are not the only one company to produce luggage packing system , but we are the best one in term of quality. Our company bears social responsibilities. We manufacture products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.

1. The material of Guangdong Smart Weigh Packaging Machinery Co., Ltd will not take any bad effect on people during use. An increased efficiency can be seen on the smart Weigh packing machine

2. Works can get rid of jobs that are dirty dull. They will take more interest in their work and their efficiency will increase. Auto-adjustable guides of Smart Weigh packaging machine ensure precise loading position

3. The product is offered after testing against various quality measures. Smart Weigh vacuum packaging machine is set to dominate the market

4. Advanced testing equipment and perfect quality assurance system ensure the automated packaging systems ltd 's high performance. Smart Weigh pouch is a great packaging for grinned coffee, flour, spices, salt or instant drink mixes

5. The product performance has been greatly improved by our innovative R&D team. Smart Weigh's uniquely designed packing machines are simple to use and are cost effective

Lettuce Leafy Vegetables Vertical Packing Machine

This is the vegetable packing machine solution for the height limit plant. lf your workshop is with a high ceiling, another solution is recommended - One conveyor: complete vertical packing machine solution.

MACHINE LIST

1. Incline conveyor

2. 5L 14 head multihead weigher

3. Supporting platform

4. Incline conveyor

5. Vertical packing machine

6. Output conveyor

7. Rotary table

SPECIFICATION

Model | SW-PL1 |

Weight (g) | 10-500 grams of vegetables |

Weighing Accuracy(g) | 0.2-1.5g |

Max. Speed | 35 bags/min |

Weigh Hopper Volume | 5L |

| Bag Style | Pillow bag |

| Bag Size | Length 180-500mm, width 160-400mm |

Control Penal | 7" Touch Screen |

Power Requirement | 220V/50/60HZ |

APPLICATION

Leafy vegetables

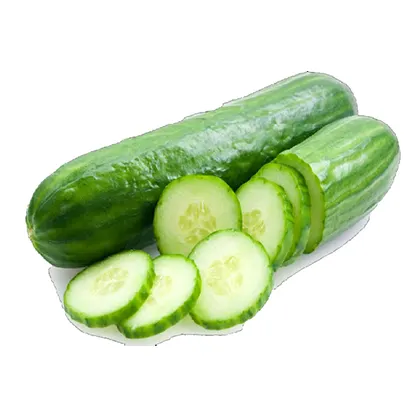

Cucumbers

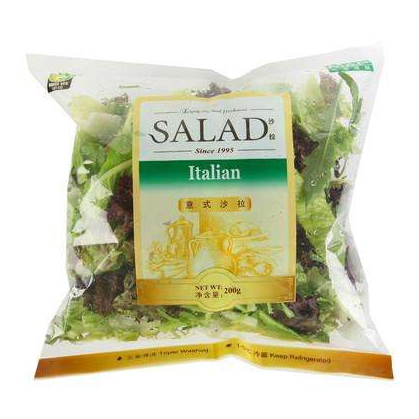

Salad Pillow Bag

FEATURES

The salad packaging machine fully-automatically procedures from material feeding, weighing, filling, forming, sealing, date-printing to finished product output.

1

Incline feeding vibrator

The incline angle vibrator makes sure the vegetables flow earlier. Lower cost and efficient way compared with belt feeding vibrator.

2

Fixed SUS vegetables separate device

Firm device because it is made of SUS304, it could separate the vegetable well which is feed from the conveyor. Well and continuous feeding is good for weigher accuracy.

3

Horizontal sealing with the sponge

The sponge could eliminate the air. When the bags is with nitrogen, this design could ensure the nitrogen percent as much as possible.

Company Features

1. Smartweigh Packing Machine is a professional high-tech enterprise, specialized in manufacturing automated packaging systems ltd . We have a top R&D team to keep improving quality and design for our automatic packing system .

2. The cutting-edge technology adopted in advanced packaging systems helps us win more and more customers.

3. We are not the only one company to produce luggage packing system , but we are the best one in term of quality. Our company bears social responsibilities. We manufacture products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources.

{{scoreAvg}}

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

Contact Us

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

Contact us

Leave your inquiry, we will provide you with quality products and services!

Contact us

whatsapp

Contact customer service

Contact us

whatsapp

cancel

Customer service