Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

Sus304 food safe grade protein powder packing machine

Whey protein powder filling machine with vertical packaging machine is the mature automation packaging technology that help you save material cost, reduce labor cost and improve efficiency.

About Smart Weigh

Smart Package Beyond Expected

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

Send Your Inqulry

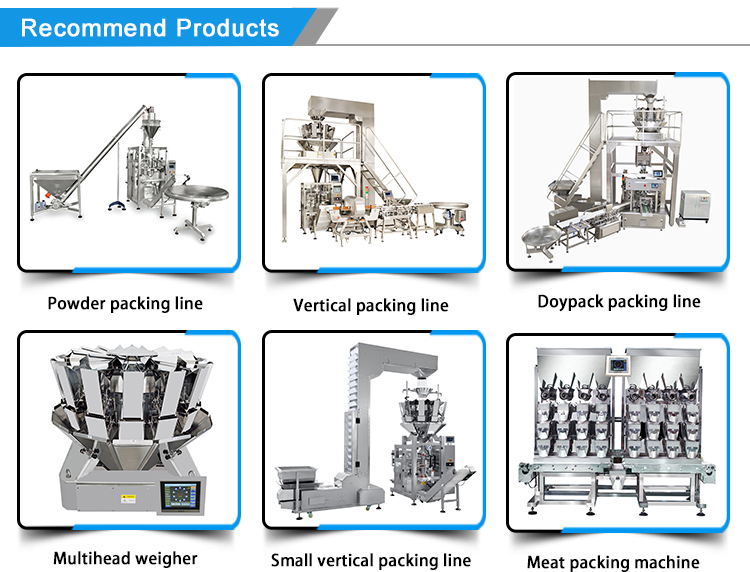

More Choices

Whey protein powder filling machine with vertical packaging machine is the mature automation packaging technology that help you save material cost, reduce labor cost and improve efficiency. This powder packaging machine is not only fit for protein powders, but also for glucose powder, coffee powder, milk powder and more.

Feature:

1). Fully-automatically procedures from material feeding, filling and bag-making, date-printing to finished products output;

2). Because of the unique way of mechanical transmission, so its simple structure, good stability and strong ability to over loading.;

3). Multi-languages touch screen for various clients, English, French, Spanish, etc;

4). Servo motor driving screw is characteristics of high-precision orientation, high-speed, great-torque, long-life, setup rotate speed, stable performance;

5). Side-open of the hopper is made of stainless steel and is consist of glass,damp. material movement at a glance through the glass,air-sealed to avoid the leak, easy to blow the nitrogen, and the discharge material mouth with the dust collector to protect the workshop environment;

6). Double film pulling belt with servo system;

7). Only control touch screen to adjust bag deviation. Simple operation.

Specifications:

Model | SW-PL2 |

Weighing Range | 10 - 1000 g |

Bag Size | 80-350mm(L) ; 50-250mm(W) |

Bag Style | Pillow Bag; Gusset Bag; Four side seal |

Bag Material | Laminated film; Mono PE film |

Film Thickness | 0.04-0.09mm |

Speed | 40 - 120 times/min |

Accuracy | 100 - 500g,≤±1%; > 500g,≤±0.5% |

Hopper Volume | 45L |

Control Penal | 7" Touch Screen |

Air Consumption | 0.8Mps 0.4m3/min |

Power Supply | 220V/50HZ or 60HZ; 15A; 4000W |

Driving System | Servo Motor |

Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425