bulk production plastic pouch packaging machine quality assurance | Smart Weigh

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. plastic pouch packaging machine We promise that we provide every customer with high-quality products including plastic pouch packaging machine and comprehensive services. If you want to know more details, we are glad to tell you.When it comes to our plastic pouch packaging machine, we are proud to say that we utilize only the best in refrigeration technology. Our system incorporates top-of-the-line compressors and electrical components, ensuring optimal performance and efficient cooling capabilities. With a speedy cooling time, you'll never have to wait long for refreshing coolness. Trust us to provide you with a reliable and high-performing refrigeration system that meets all your needs.

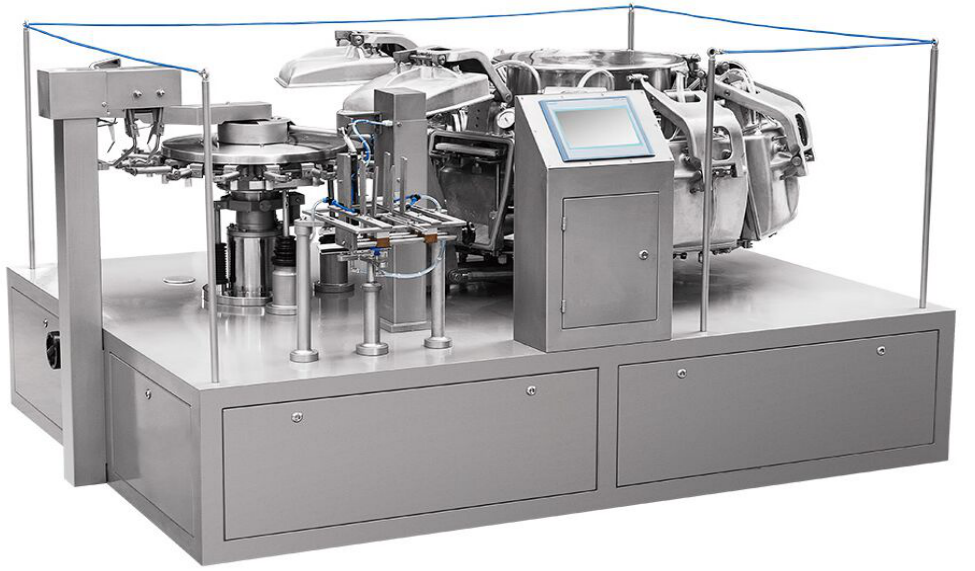

A wet pet food vacuum pouch packing machine is an advanced packaging solution designed to efficiently package moist pet foods, such as chunks in gravy or pâtés, into vacuum-sealed pouches. This technology ensures product freshness, extends shelf life, and maintains the nutritional quality of the pet food by removing air and preventing contamination.

Automated Operation: Streamlines the packaging process by automatically filling, sealing, and labeling pouches, enhancing production efficiency and consistency.

Multihead Weigher Precision: Incorporates a multihead weighing system that ensures precise measurement of wet pet food portions, even for sticky or irregularly shaped products. This precision minimizes product giveaway and ensures consistent package weights, enhancing both cost efficiency and customer satisfaction.

Vacuum Sealing Technology: Removes air from the pouch, preventing oxidation and inhibiting bacterial growth, which helps preserve the food's quality and flavor.

Versatility in Pouch Types and Sizes: Capable of handling various pouch sizes and types, including stand-up pouches and retort bags, accommodating different product volumes and marketing preferences.

Hygienic Design: Constructed with food-grade materials and designed for easy cleaning to meet stringent sanitation standards in pet food production.

| Weight | 10-1000 grams |

| Accuracy | ±2 grams |

| Speed | 30-60 packs/min |

| Pouch Style | Premade Pouches, stand-up pouches |

| Pouch Size | Width 80mm ~ 160mm, length 80mm ~ 160mm |

| Air Consumption | 0.5 cubic meter/min at 0.6-0.7 MPa |

| Power & Supply Voltage | 3 Phase, 220V/380V, 50/60Hz |

Types of Wet Pet Foods: Suitable for packaging a range of products, such as tuna meat with liquid or jelly.

Industry Use Cases: Applicable for medium and large-scale pet food manufacturers and large production facilities.

●Enhanced Product Shelf Life: Vacuum sealing significantly extends the shelf life of tuna meat with liquid or jelly.

●Reduced Spoilage and Waste: Precise weighing and sealing minimize product waste and spoilage, leading to cost savings.

●Attractive Packaging: High-quality packaging options enhance product appeal on store shelves, attracting more customers.

Multihead Weigher Handle Well The Wet Pet Food

Our multihead weigher is designed to handle the precise weighing of sticky products such as tuna meat. Here’s how it stands out:

Accuracy and Speed: Utilizing advanced technology, our multihead weigher ensures accurate weight measurement at high speeds, reducing product giveaway and enhancing efficiency.

Flexibility: It can handle a variety of product types and weights, making it ideal for different packaging sizes and formats.

User-Friendly Interface: The machine features an intuitive touchscreen interface for easy operation and quick adjustments.

Vacuum Pouch Packing Machine for Wet Pet Food

Pairing the multihead weigher with our vacuum pouch packing machine ensures that the wet pet food packing is packed to the highest standards of freshness and quality:

✔Vacuum Sealing: This technology removes air from the pouch, extending the shelf life of the product and preserving its nutritional value and flavor.

✔Versatile Packaging Options: Our machine can handle different types of pouches, including stand-up pouches, flat pouches, and quad seal bags, providing flexibility for various market needs.

✔Hygienic Design: Made from stainless steel, the machine is easy to clean and maintain, ensuring compliance with food safety standards.

✔Customizable Features: Options for additional features such as resealable zippers and tear notches enhance consumer convenience.

Quick Link

Packing Machine