Custom filling equipment for business Manufacturer | Smart Weigh

Over the years, Smart Weigh has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. filling equipment Smart Weigh have a group of service professionals who are responsible for answering questions raised by customers through the Internet or phone, tracking the logistics status, and helping customers solve any problem. Whether you'd like to get more info on what, why and how we do, try our new product - Hot Selling filling equipment for business, or would like to partner up, we'd love to hear from you.Smart Weigh filling equipment is designed with reasonable and optimized dehydrating structure by our professional designers who have many years of experience in creating different types of food dehydrators for various applications.

The machine is composed of granule filling head, chain plate conveyer belt and positioning device. It can complete automatic positioning, filling and measuring work of the bottle. Using servo (or step) motor and PLC touch screen, the operation is simple and the stability is high. It can be made up of a full set of filling line with the bottle cutting machine, the rotating cover machine and the labeling machine. Suitable for packing of powder and granule materials, such as powder, small granules medicine, veterinary medicine, glucose, spices, solid beverage, carbon powder, talcum powder, pesticide etc.. It can be installed on the basis of different materials, and can also produce two, three and four equipment according to the requirements of the packing speed.

Weighing range | 10-1500g 10-3000g |

Weighing accuracy | 0.1-1.5g 0.2-2g |

Max filling speed | 60cans/min |

Hopper capacity | 1.6L/2.5L |

Power supply | AC220V 50/60Hz |

Machine size | L1960*W4060*H3320mm |

Weight | 1000kg |

※ Features

Factory price Gum Candy PET Jar Packing Machine Snack Food Granule Jar Filling Capping Labeling Machine

1. | Fast filling speed and high accuracy | |||

2. | Advanced man-machine interface operation, PLC control | |||

3. | Stainless steel appearance material, fully in line with food hygiene standards; | |||

4. | This equipment is suitable for weighing and filling those materials, such as, rice, dried fruit, Chinese medicine slices, biscuits etc. which has wide range of applications | |||

1.Seaming rollers are made of stainless steel with high hardness and never rusty with excellent sealing performance.

non rotation of can body in the process of sealing ,which avoids shift and scatter of product put well in the can.

1. Weighing range: 10-1500g 10-3000g

2. Weighing accuracy: 0.1-1.5g 0.2-2g 3. Max. filling speed: 60cans/min 4. Hopper capacity: 1.6L/2.5L 5. Control System: MCU 6. Touch screen: 7 inches 7. Power supply: AC220V 50/60Hz 8. Size: L1960*W4060*H3320mm9. Weight: 1000kg

10.Machine power: 3 kw(about)

For more information, please feel free to contact me.......

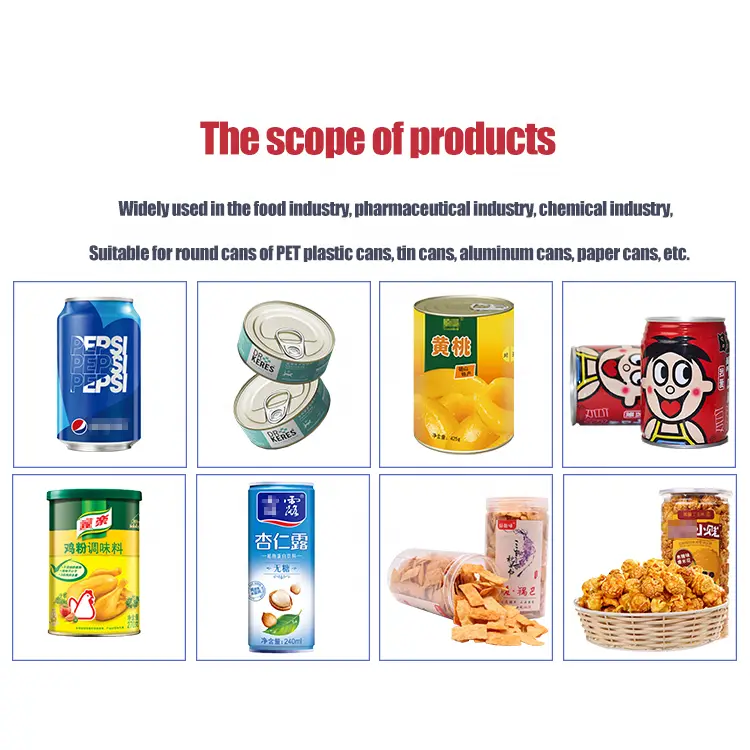

※ Application

Scope of application: Laundry gel beads, wolfberry, nuts and other granular quantitative weighing packaging;

Filling containers: bottles; plastic cans; glass cans; tinplate cans; cartons, etc.

※ Function

※ Product Certificate

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425