Smart Weigh | High End food tray sealing machine

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. food tray sealing machine Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product food tray sealing machine or our company, feel free to contact us. attaches great importance to product quality, regards quality as the life of the enterprise, and strictly controls quality in various links such as raw material selection, spare parts processing, manufacturing, assembly test machine, delivery inspection, etc., to ensure that food tray sealing machine produced are of stable quality, Quality safe and reliable products.

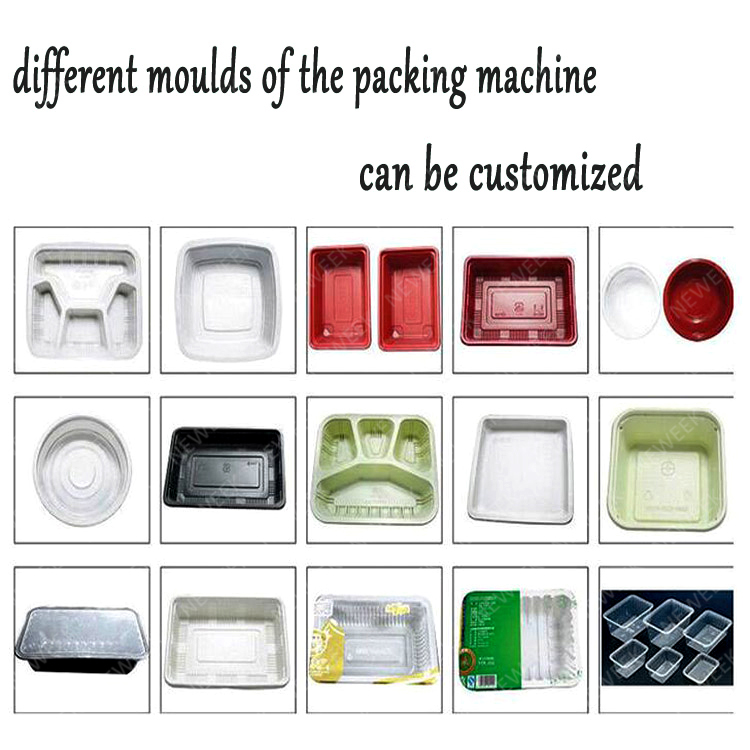

Automatic Feeding and Filling Tray Denester Tray Packing Machine

| Model | SW-T1 |

| Tray Size | L=100-280 W=85-245 |

| Speed | 30-60 trays/min(can feed 400 trays per time) |

| Tray Shape | Square, round type |

| Tray Material | Plastic |

| Control Panel | 7" touch screen |

| Power | 220V, 50HZ or 60HZ |

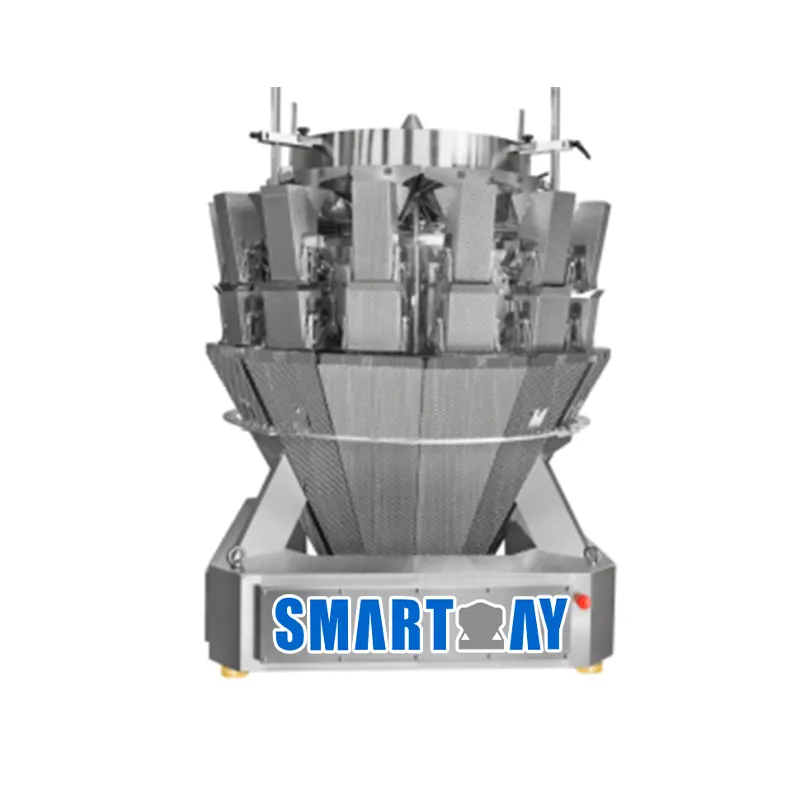

Multihead Weigher For Fresh Vegetable Mushroom

IP65 waterproof, use water cleaning directly, save time while cleaning;

Modular control system, more stability and lower maintenance fees;

Production records can be checked at anytime or download to PC;

Load cell or photo sensor checking to satisfy different requirements;

Preset stagger dump function to stop blockage;

Design linear feeder pan deeply to stop small granule products leaking out;

Refer to product features, select automatic or manual adjust feeding amplitude;

Food contact parts disassembling without tools, which is easier to clean;

Multi-languages touch screen for various clients, English, French, Spanish, etc;

PC monitor production status, clear on production progress (Option)

tray denester

tray denesterThe tray feeding belt can load more than 400 trays, reduce the times of feeding tray;

Different tray separate way to fit for different material's tray, rotary separate or insert separate type for option;

The horizontal conveyor after the filling station can keep the same distance between every tray.

Auto separate tray or cup filling individually

Full stainless steel 304 frame with water proof design, to working in high humidity environment;

Different tray dimension replacement without tool, save production time;

Automatic or manual lifting material is available, carry speed also can be adjusted;

Carry belt is make of good grade PP, suitable to work in high or low temperatur

Tray denesting and dispensing

Quick Link

Packing Machine