Smart Weigh | stable weighing and packing machine quality assurance

Guided by scientific and technological innovation, Smart Weigh always keeps outward-oriented and sticks to the positive development on the basis of technological innovation. weighing and packing machine Having devoted a lot to product development and service quality improvement, we have established a high reputation in the markets. We promise to provide every customer throughout the world with prompt and professional service covering the pre-sales, sales, and after-sales services. No matter where you are or what business you are engaged in, we'd love to help you deal with any issue. If you want to know more details about our new product weighing and packing machine or our company, feel free to contact us.Smart Weigh is developed creatively by the R&D team. It is created with dehydrating parts including heating element, a fan, and air vents which are essential in the air circulating.

Main parameters: | |||

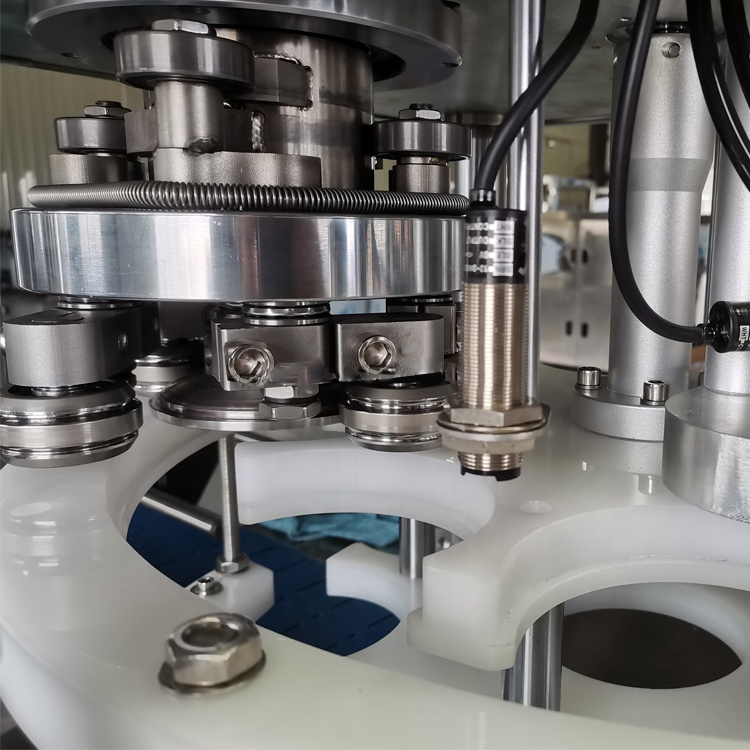

Number of sealing head | 1 | ||

Number of seaming rollers | 4 (2 first operation, 2 second operation) | ||

Sealing speed | 33 cans/ min (Not adjustable) | ||

Sealing height | 25-220mm | ||

Sealing can diameter | 35-130mm | ||

Working temperature | 0-45℃ | ||

Working humidity | 35-85% | ||

Working power supply | Single-phase AC220V S0/60Hz | ||

Total power | 1700W | ||

Weight | 330KG (about) | ||

Dimensions | L 1850 W 8404H 1650mm | ||

※ Features

Features: | ||||

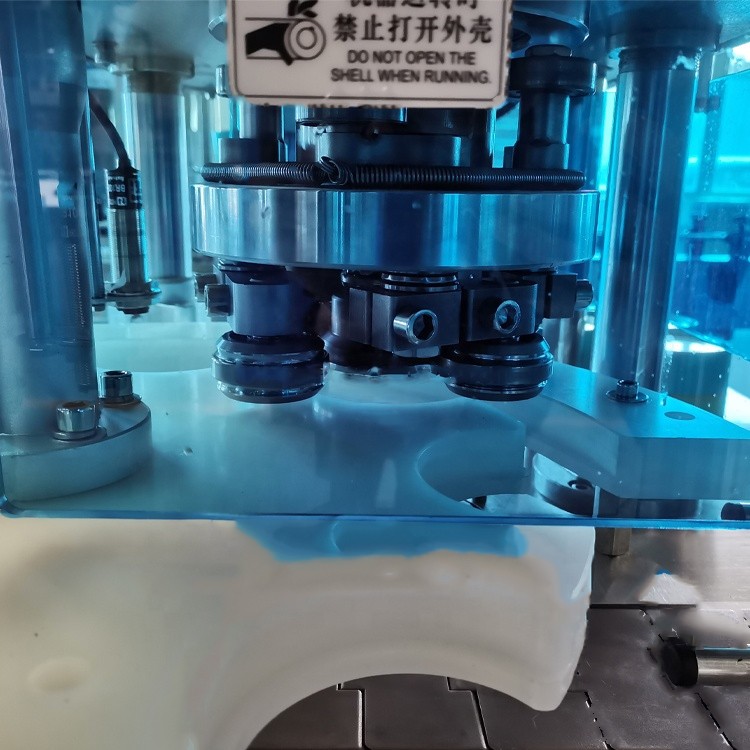

1. | Whole machine servo control makes the equipment run safer, more stable and smarter. The turntable only runs when there is a can, speed can be adjusted separately: when there is can stuck, the turntable will automatically stop. Ater one button reset, the error can be released and machine restart to run: When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial Equipment damage and safety accidents caused by incorre coperation of the equipment. | |||

2. | A total of a seaming rollers are completed at the same time to ensure high sealing performance | |||

3. | The can body does not rotate during the sealing process, which is safer and is especially,suitable for fragile and liquld products. | |||

4. | The sealing speed is fixed at 33 cans per minute, production is automated, which improvesproduction efficiency and saves labor costs. | |||

※ Features

Appliacation

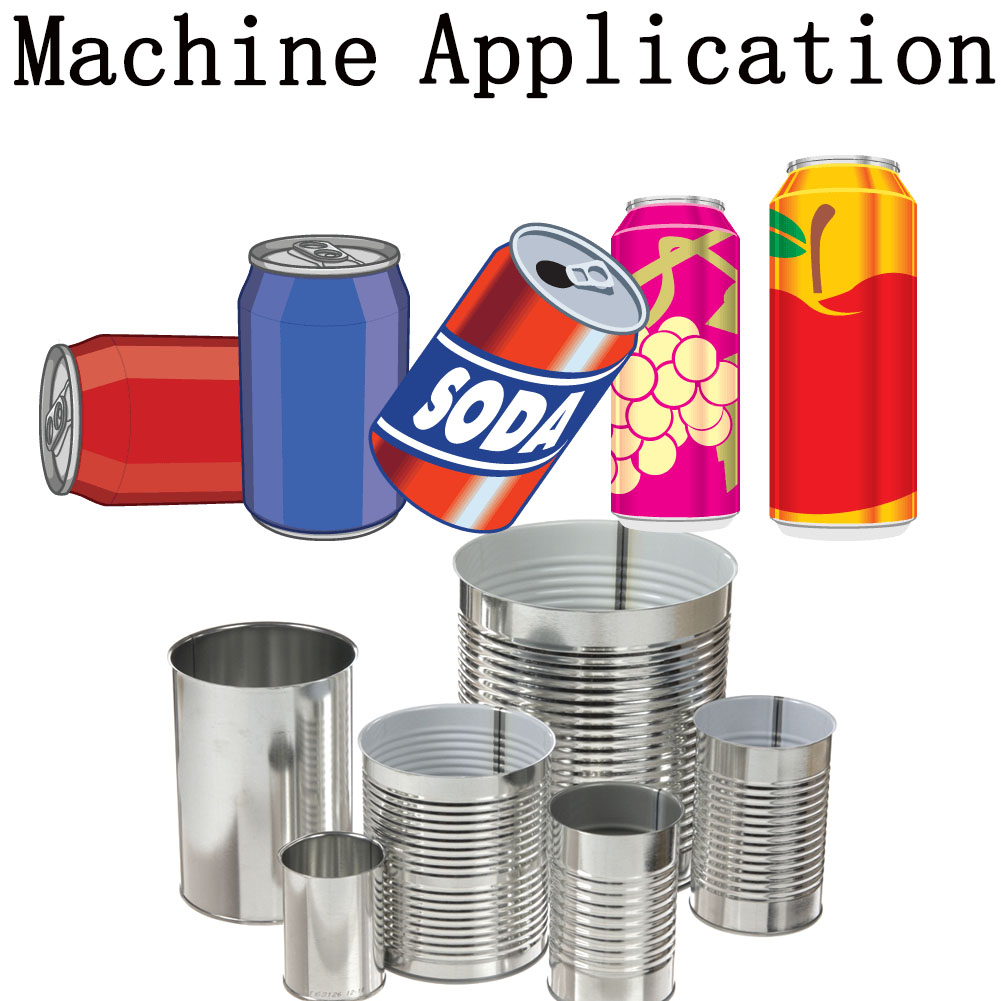

Applicable to tin cans, aluminum cans, plastic cans and composite paper can, it is the idea packaging equipment for food, beverage, Chinese medicine drinks, chemical industry etc.

※ Complete Solutions

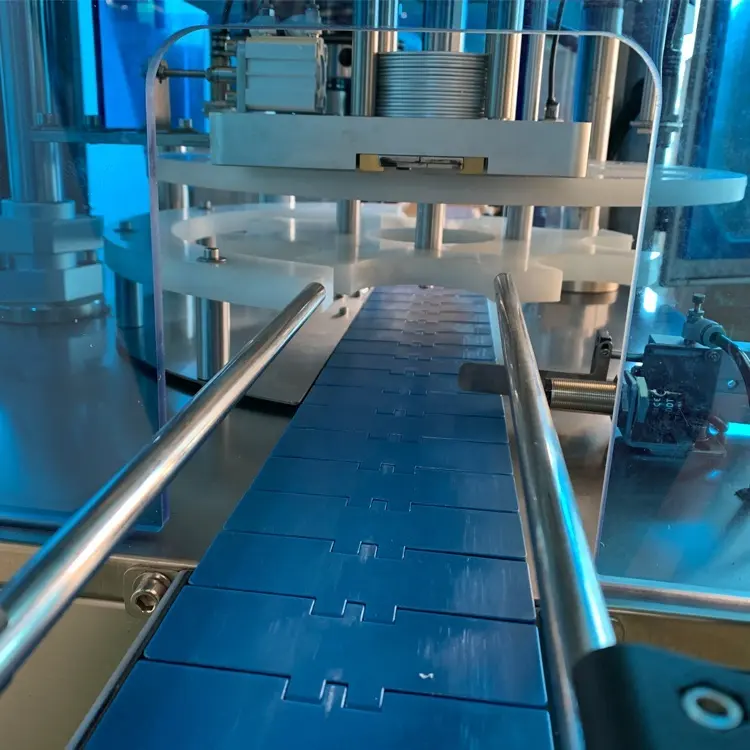

The tin sealing machines can equip with other packaging machines to be a complete solutions for tin cans, the whole line machine list: infeed conveyor, multihead weigher with tin can filler, empty tin cans feeder, tin sterilization(optional), can sealing machine, capping machine(optional), labeling machine and finished can collector.

The filling machine system (multihead weigher with tin can rotary filling machines) ensure the accurate and efficient performance for solid products(tuna, nuts, dried fruits), tea powder, milk powder and other industries products.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425