standard pouch packing machine manufacturer factory | Smart Weigh

After years of solid and rapid development, Smart Weigh has grown into one of the most professional and influential enterprises in China. pouch packing machine manufacturer Today, Smart Weigh ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product pouch packing machine manufacturer and our company by directly contacting us.Smart Weigh goes through rigorous quality and safety testing. To ensure its durability, our quality control team conducts salt spray and high-temperature tests on its food tray, examining its ability to withstand corrosion and heat. Trust that your Smart Weigh products are built to last.

Screw weigher rotary packing line can be used to weigh a variety of sticky foods, including pickle products, kimchi, preserves, etc.

Bag types:zipper bags, stand up pouch, flat bags, doypack bags, etc.

Viscous material weighing and pickle pouch packing machine.

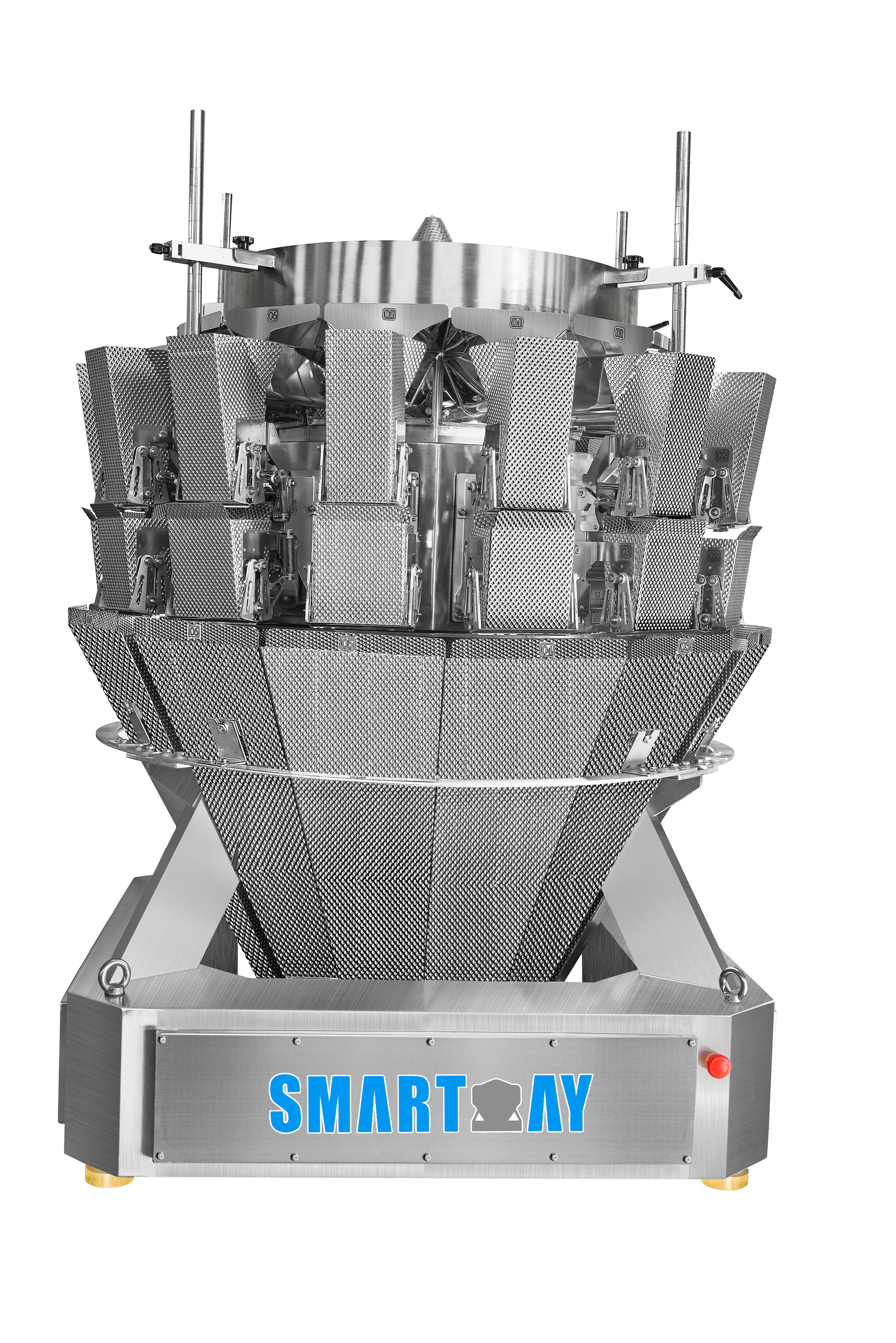

Screw multihead Head Weigher has a long service life and is simple to maintain. Flexible hopper design, simple disassembly, IP65 waterproof rating, and simple cleaning. Clean and hygienic SUS304 stainless steel, no contamination. Screw feeding weigher is protected by heating accessories to ensure smooth operation in humid conditions or low temperature.

n IP65 waterproof, use water cleaning directly, save time while cleaning.

n Auto feeding, weighing and delivery sticky product into bagger smoothly.

n Screw feeder pan handle sticky product moving forward easily.

n Scraper gate prevents the products from being trapped into or cut. The result is more precise weighing.

n Modular control system, more stability and lower maintenance fees.

n Production records can be checked at anytime or download to PC.

n Rotary top cone to separate the sticky products onto linear feeder pan equally, to increase speed & accuracy.

n All food contact parts can be take out without tool, easy cleaning after daily work.

n Special heating design in electronic box to prevent high humidity and frozen environment.

n Multi-languages touch screen for various clients, English, French, Spanish, Arabic etc.

n PC monitor production status, clear on production progress (Option).

CE Automatic Pickle Food Fried Rice Cooked Rice Vacuum Packing Machine

Using high technology such as a microcomputer display and a graphic touch panel, the machine can be easily performed operation and maintenance

Packing machine rotates intermittently to fill the product easily and vacuum machine rotates continuously to enable smooth running, it means high performance and high durability.

All grippers’width of packing machine can be adjusted at once by a motor but all grippers in the vacuum chambers are no need to adjust. Main sections are made of stainless steel for excellent durability and hygiene.

Weighing machine and liquid &paste meters can be combined with this machine Status in the vacuum chamber can be checked through the transparent plastic vacuum shell lids.

function | Giving bag, coding, opening, fill consolidate1, fill consolidate2, vacuum and sealing, output products |

Packing materials | Preformed bag |

Bag size | W:150-200mm L:150~300mm |

Filling Accuracy | ±0.1-3.5 grams |

Filling volume | 10-1500g (depending on type of product and pouch size) |

speed | 20-30bags/min(the speed depends on the products status and filling weight) |

Total power | 220V/380V,3phase,50/60Hz,16kw |

Compress air requirement | 350N liter/min, 6Kg/cm2 |

Smart Weight provides you with an ideal weighing and packaging solution. Our weighing machine can weigh particles, powders, flowing liquids and viscous liquids. The specially designed weighing machine can solve the weighing challenges. For example, the multi head weigher with dimple plate or Teflon coating is suitable for viscous and oily materials, the 24 head multi head weigher is suitable for mixture flavor snacks, and the 16 head stick shape multi head weigher can solve the weighing of stick shape materials and bags in bags products. Our packaging machine adopts different sealing methods and is suitable for different bag types. For example, vertical packaging machine is applicable to pillow bags, gusset bags, four side seal bags, etc., and the premade bag packaging machine is applicable to zipper bags, stand up pouches, doypack bags, flat bags, etc. Smart Weigh can also plan the weighing and packaging system solution for you according to the actual production situation of customers, so as to achieve the effect of high precision weighing, high efficiency packing and space saving.

Quick Link

Packing Machine