stand up pouch doypack bag packing snacks and banana chips packaging machine

Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

SmartWeigh automatic rotary doypack premade bag nachos packaging machine for snack chips

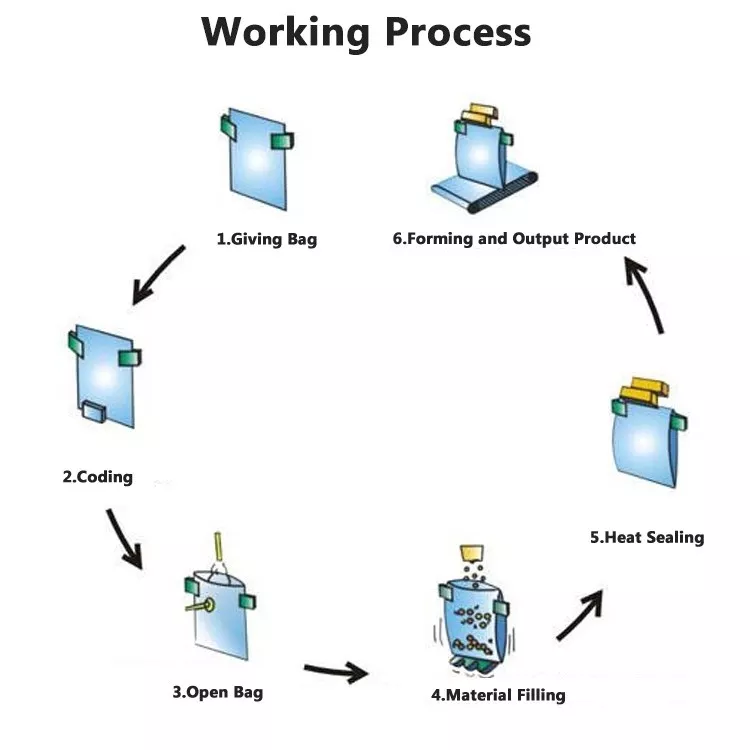

Working flow:giving bag→coding →opening →filling 1 →filling 2→ auxiliary→ exhaust→heat sealing→ .forming and output product

1. It uses stainless steel 304 shell for food grade required.

2. Automatic detection. No pouch or pouch is not opened completely, no filling, no sealing.

3. Horizontal Infeed conveyor suits for bags with zipper, max. put 300pcs each time.

4. Zipper Openner System: Servo motor (Yaskawa / Japan) controlled.

5. Independent temperature control system (Omron/Japan).

6. PLC adjust bag width clamping: Only needs 2mins by auto PLC for adjust different bag width sizes.

7. Automatic lubrication system: PLC control the lubrication time,automatically lubricate the machine parts instead of by manual.

8. It includes ribbon type date code: 3 lines * 17 characters.

9. Guarding: Glass Door Alarm / Air Pressure Abnormal

10. Internal grooved cam design: The technology with high precision, suits for max. packing

speed: 50 cycles/min with stable running.

11. Use free oil vacuum pump, avoid polluting the environment in the production.

1.Code printer

2.PLC control system

3.Bag opening device

4.Vibration device

5.Cylinder

6.Electromagnetic valve

7.Temperature controller

8.Vacuum pump

9.Inverter

10.Output system

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425