Since 2012 - Smart Weigh is committed to helping clients increase productivity at a reduced cost.

How should six different types of mixed candies be weighed and packaged?

High-precision automatic 6 flavor mixed jelly gummies weighing and packaging line from Smart Weigh has been introduced for international markets. This system can pack 35 bags per minute. Each bag contains about 6g of candy, allowing for flexible adjustment of the weight ratio of the various tastes.

Then, a Polish customer placed an order for mixed cbd confectionary packing systems to automate the weighing and packaging procedure, ensuring the sanitation and safety of food throughout manufacturing and boosting profit margins.

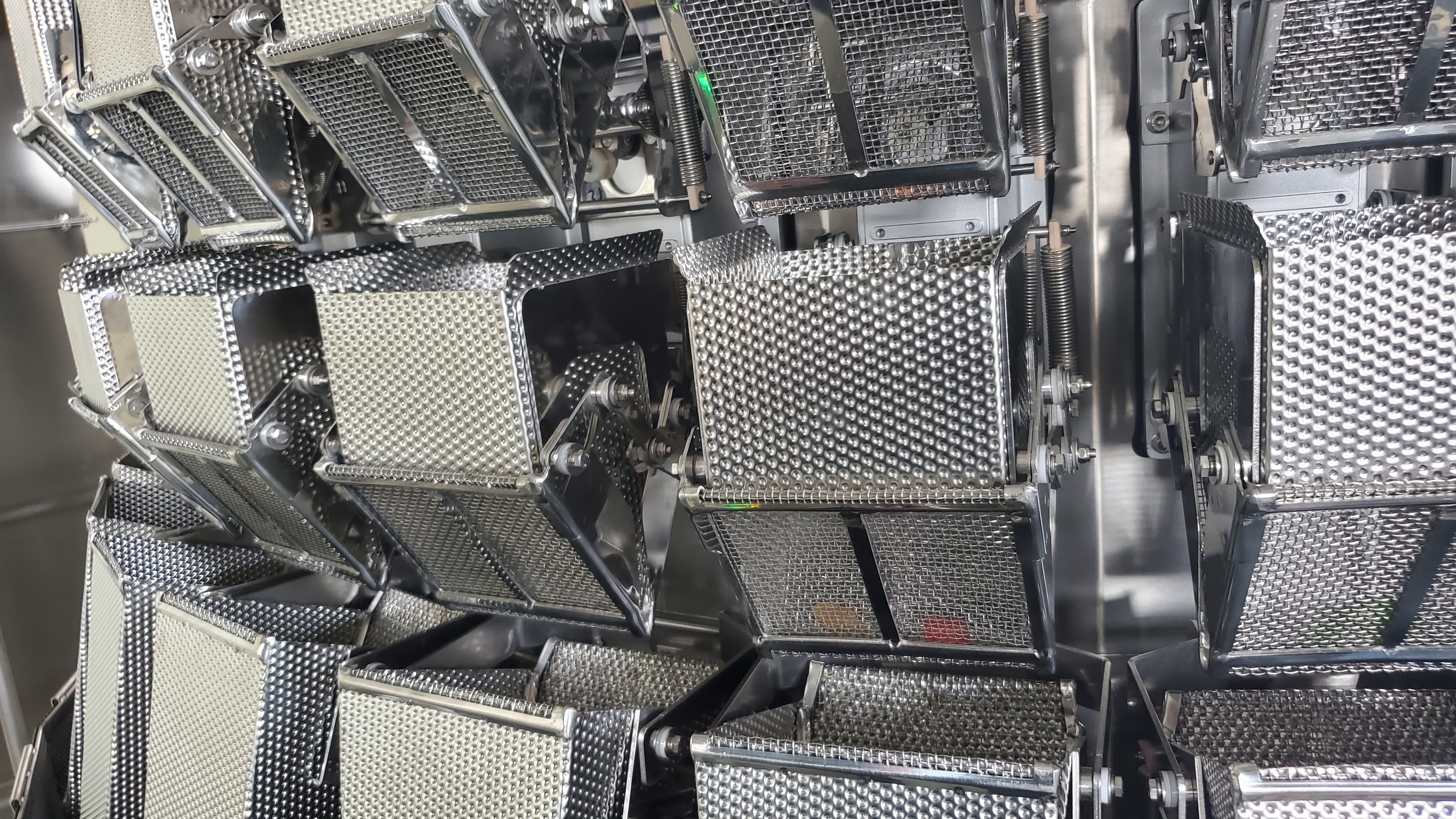

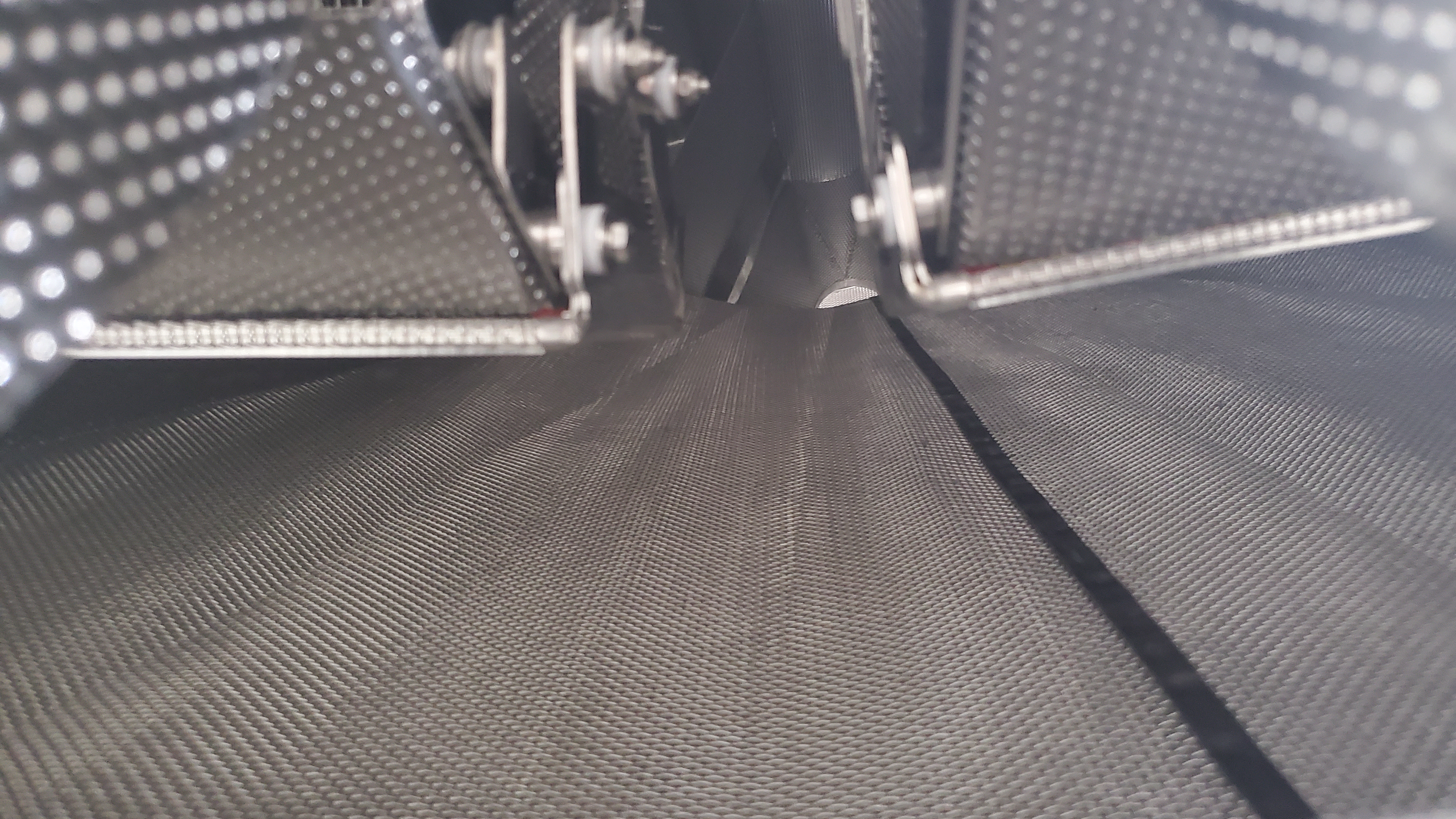

To keep the jelly gummies from sticking, the food contact area is reticulated.

There are 6 rejection channels for rejecting products with unacceptable weights and recycling to cut waste.

Packing line for sticky jelly gummies cbd confectionary

Product | Gummy candies, hard candies, nuts, and mixed-packaged foods |

Target weight | 6 mixture:14g/50g/70g/150g/350g/750g/1kg |

Bag style | Pillow bag |

Bag size | 135*177mm(50g) 120*155mm(70g) 165*205/250mm(150g/350g) 225*310m(750g,150g/1kg) |

Speed | 35 bags per minute |

1. Mixing 4 or 6 kinds of product into one bag with high speed (Up to 50bpm) and precision.

2. 3 weighing mode for selection: Mixture, twin & high speed weighing with one bagger.

3. Discharge angle design into vertically to connect with twin bagger, less collision & higher speed.

4. Select and check different program on running menu without password, user-friendly.

5. One touch screen on twin weigher, easy operation.

6. Central load cell for ancillary feed system, suitable for different product.

7. All food contact parts can be took out for cleaning without tool.

8. Check weigher signal feedback to auto adjust weighing in better accuracy.

9. PC monitor for all weigher working condition by lane, easy for production management.

10. Optional CAN bus protocol for higher speed and stable performance.

Smart Weigh is a global leader in high-precision weighing and integrated packaging systems, trusted by 1,000+ customers and 2,000+ packing lines worldwide. With local support in Indonesia, Europe, USA and UAE, we deliver turnkey packaging line solutions from feeding to palletizing.

E-mail: export@smartweighpack.com

Tel: +86 760 87961168

Fax: +86-760 8766 3556

Address: Building B, Kunxin Industrial Park, No. 55, Dong Fu Road , Dongfeng Town, Zhongshan City, Guangdong Province, China ,528425